Clutch system and clutch separation bearing assembly

A technology for separating bearings and clutches, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve problems such as difficulties in automatic centering, achieve the effects of reducing noise pollution, improving service life, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

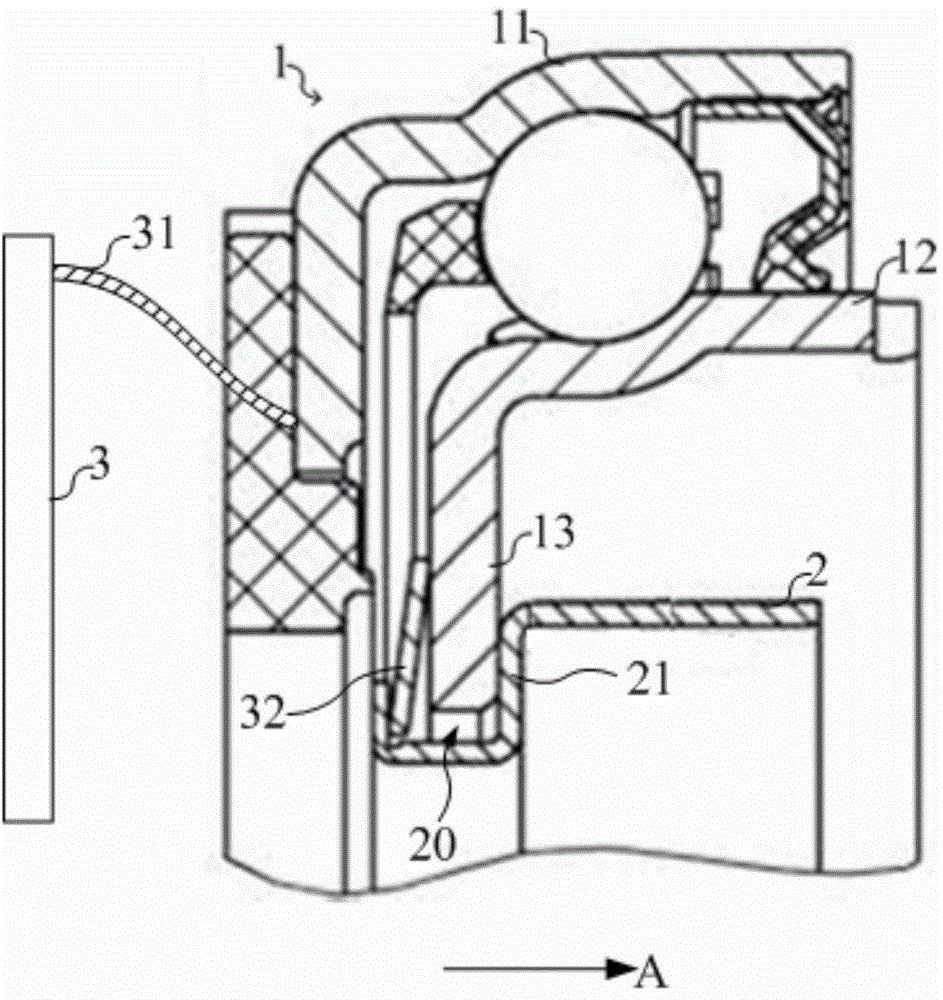

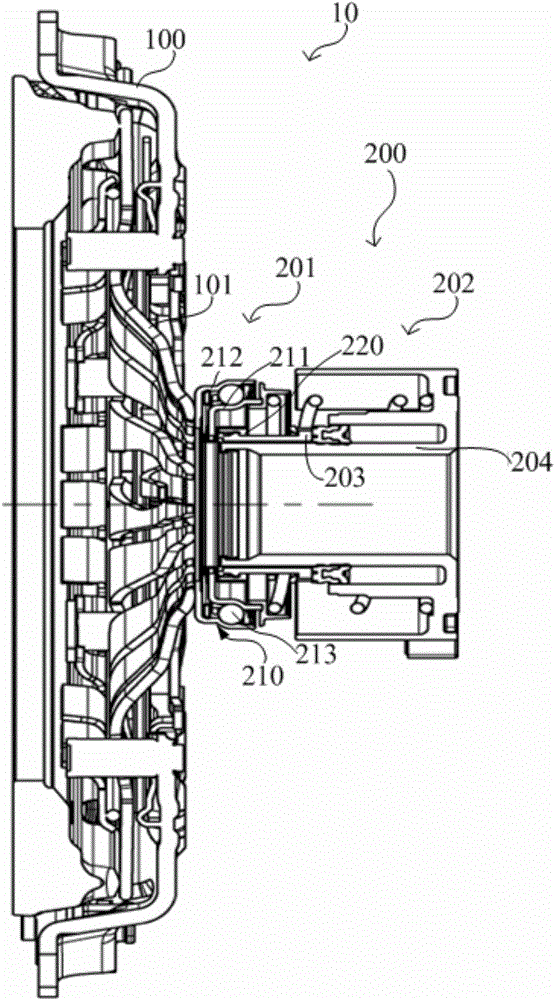

[0030] refer to image 3 , the present embodiment provides a clutch system 10, including: a clutch 100 including a diaphragm spring 101; a clutch operating mechanism 200 for controlling disengagement and engagement of the clutch 100. The clutch operating mechanism 200 includes: a release bearing assembly 201 ; and a coaxial slave cylinder (Concentric Slave Cylinder, CSC for short) 202 . The coaxial slave cylinder 202 includes: a guide sleeve 204, which has a through hole (not marked) for accommodating the input shaft of the gearbox; an annular piston 203 movably sleeved outside the guide sleeve 204, located along Axially away from the side of the clutch 100 .

[0031] refer to image 3 and Figure 4 , The release bearing assembly 201 includes: a support ring 220 connected to the piston 203 in the axial direction; an annular elastic member 230 sleeved outside the support ring 220 ; The release bearing 210 has an inner ring 211 and an outer ring 212 arranged coaxially, and a...

no. 2 example

[0049] Compared with the first embodiment, the second embodiment differs in that:

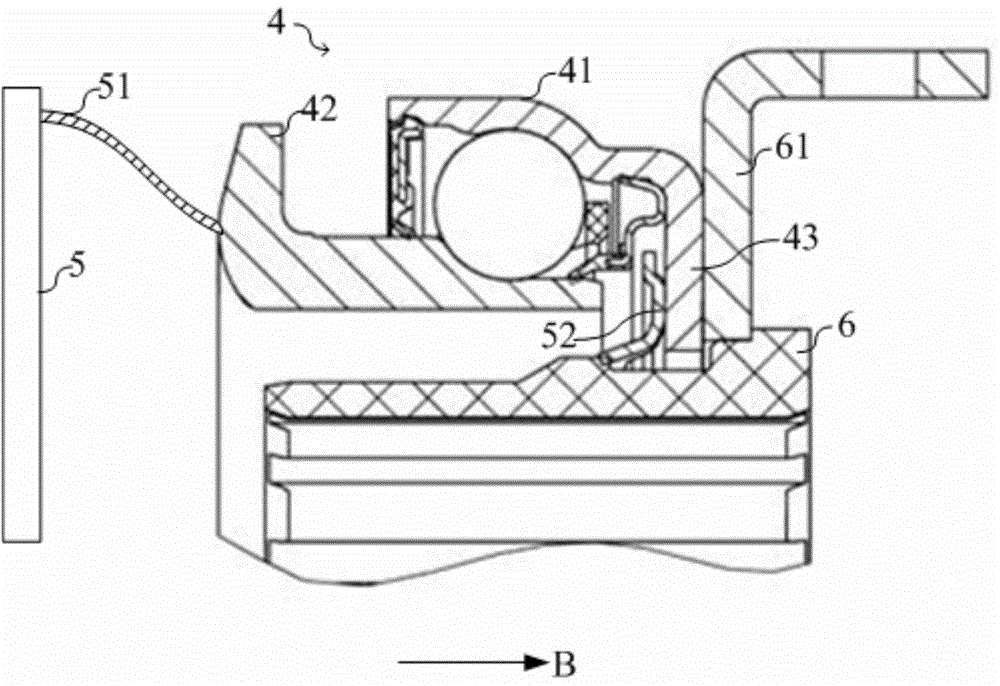

[0050] refer to Image 6 , in the release bearing 300, the inner ring 311 is a rotatable ring and the outer ring 312 is a non-rotating ring. The clutch 400 resists the inner ring 311 through the diaphragm spring 401, and the diaphragm spring 401 can rotate synchronously with the inner ring 311, wherein on the side of the release bearing 300 axially away from the clutch 400, the annular piston (not shown in the figure) ) is used to drive the outer ring 312 to move the release bearing 300 axially;

[0051] The outer ring 312 is provided with a first protrusion 314 protruding radially toward the support ring 320 and surrounding the support ring 320; the outer peripheral surface of the support ring 320 is provided with an annular protrusion 321 protruding radially toward the outer ring 312. 300 is provided with an annular stopper 322 on the side away from the clutch 400 in the axial direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com