Continuously variable transmission for storing disc with radial-adjusted long holes on torque and speed in levers

A continuously variable transmission, disc technology, applied in the direction of elements with teeth, belt/chain/gear, mechanical equipment, etc., to achieve the effect of high torque and high efficiency continuous speed change, reduce power consumption, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

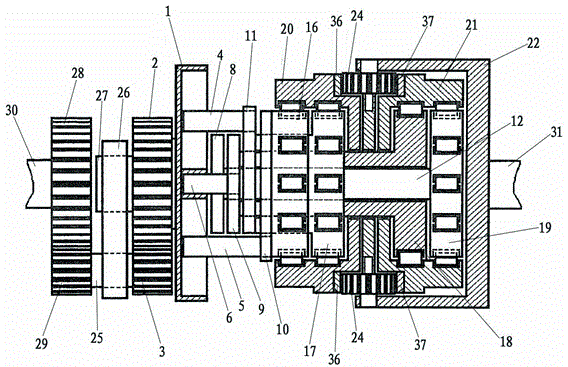

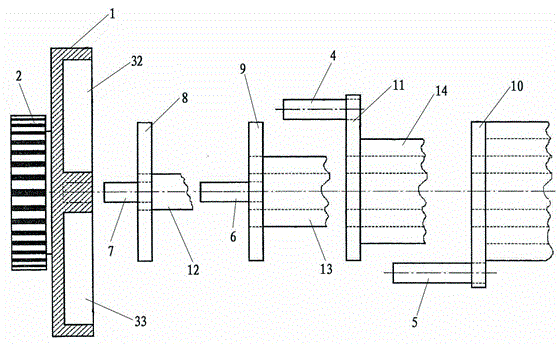

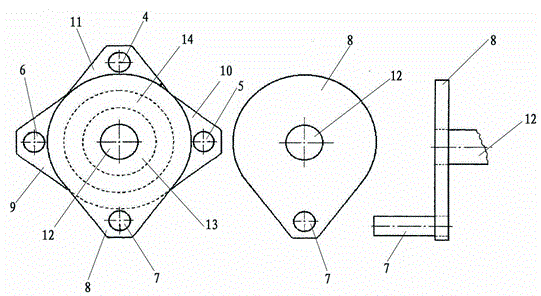

[0013] The present invention will be further described below in conjunction with accompanying drawing: be used for the continuously variable transmission that radially adjustable elongated hole disk is stored in lever on torque and speed, comprise: have at least two elongated holes and be directly or indirectly connected to driving Disc with shafts, with at least two gears and guides for the levers in the elongated disc, with at least two levers mounted eccentrically on the elliptical disc, with at least one shaft on which the elliptical disc is guided, with at least one flywheel , having at least one flywheel housing in which at least one flywheel is integrated and which is directly or indirectly coupled to the drive shaft.

[0014] figure 1 An example of a continuously variable transmission with variable speed and torque is shown. Such as Figure 4 As shown, the transmission has inside a slotted disc (1) on which there are four slotted holes (32,33,34,35) on which the leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com