Rubber pipe for turbo-charging air pump and manufacturing method thereof

A technology for turbocharging and manufacturing methods, applied in applications, hoses, pipes, etc., can solve the problems of TurboLag becoming larger, reducing the temperature of the supercharger, lengthening the heat dissipation path, etc., to improve stability, enhance strength, improve The effect of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

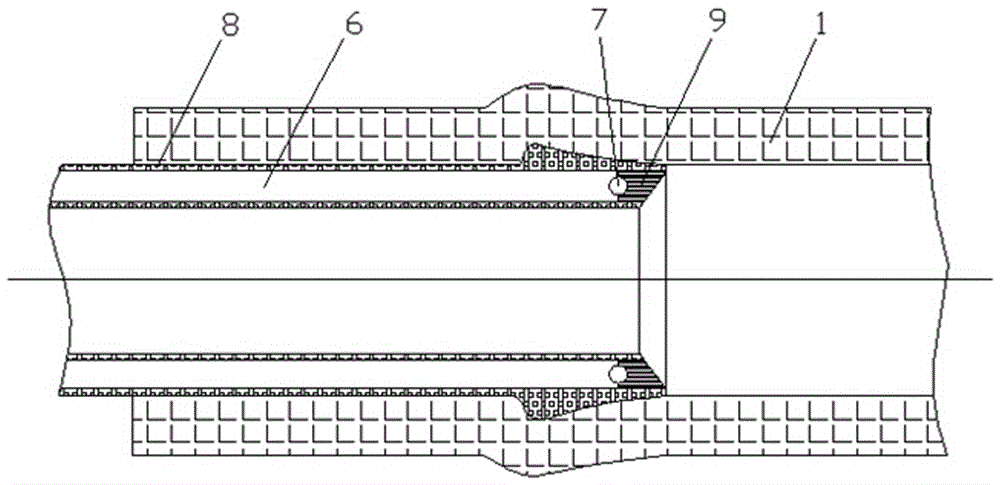

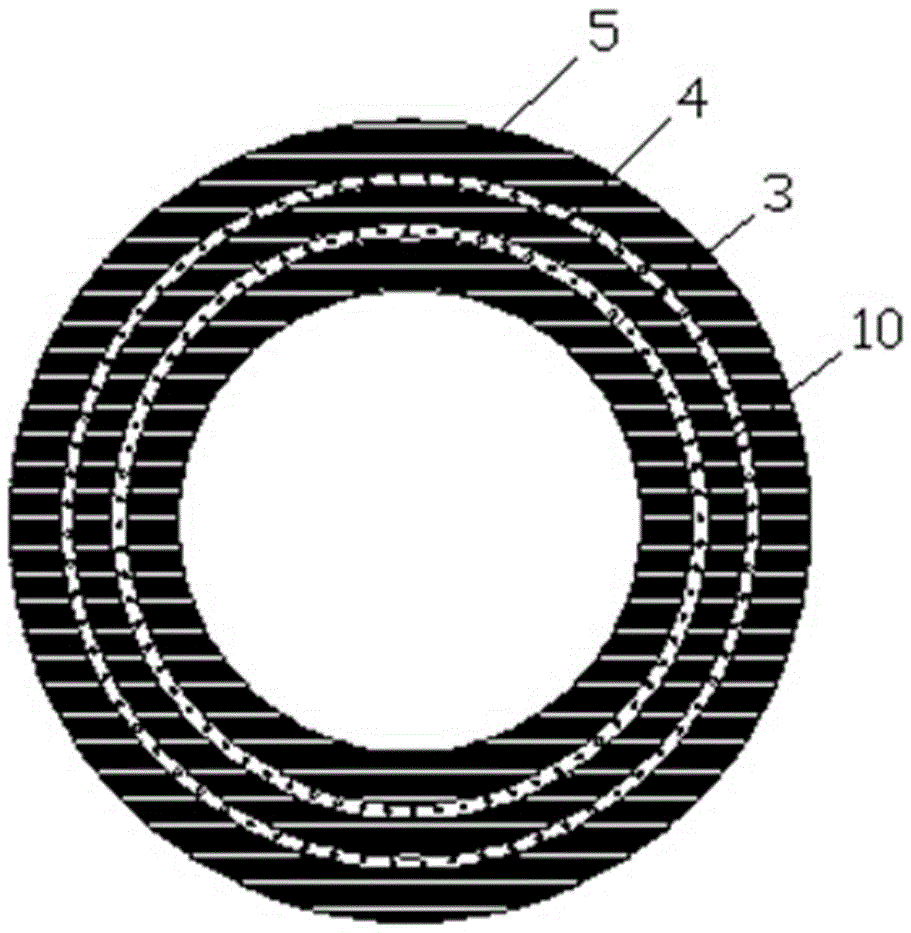

[0057] Such as Figure 1-4 As shown, it is a rubber tube for a turbocharged air pump described in this embodiment, which sequentially includes an inner rubber layer 3, a fiber thread reinforcement layer 4 and an outer rubber layer 5 from the inside to the outside, the inner rubber layer 3 and the outer rubber layer 5. Outer rubber layer 5 all comprises following component:

[0058] Fluorosilicone rubber 82 parts by weight

[0059] Vulcanizing agent double two four 2.8 parts by weight

[0060] Vulcanizing agent 225 1.2 parts by weight

[0061] 0.5 parts by weight of stearic acid

[0062] Camel powder 8 parts by weight

[0063] Butylbenzene 0.2 parts by weight

[0064] Zinc oxide 0.3 parts by weight

[0065] Anti-double agent AA-801 2 parts by weight

[0066] Heat resistant agent 2 parts by weight

[0067] 1 part by weight of antioxidant RD.

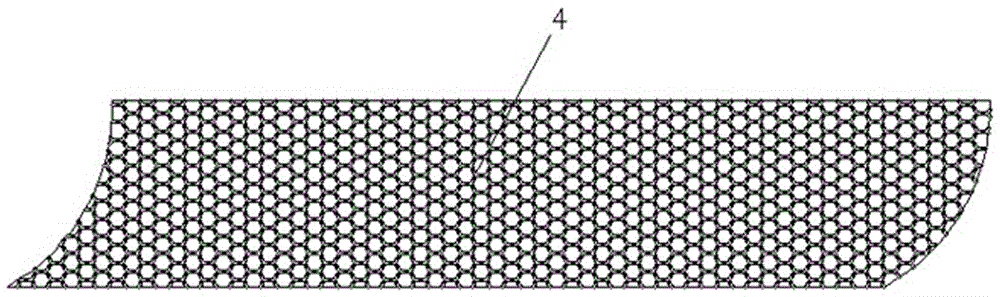

[0068] Specifically, expand as figure 1 and image 3 As shown, the fiber thread reinforcement layer 4 is an aramid thread laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com