Smoke-preventing combustion machine

A burner and flue gas technology, which is applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of flue gas diffusion and environmental pollution, and achieve the effect of avoiding flue gas diffusion and preventing backflow into the feeding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

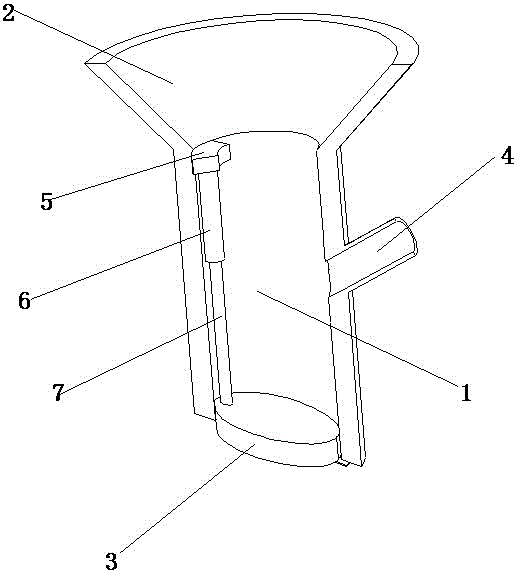

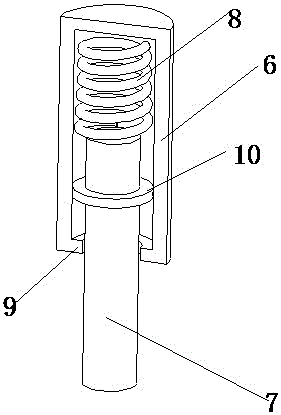

[0012] Such as figure 1 , 2 As shown, the present invention provides an anti-smoke burner, which includes a feed pipe 1, a sleeve rod 6, a linkage rod 7 and a flap 3. The lower end surface of the feed pipe 1 is a slope surface, and the flap 3 is located on the feed pipe 1, the flap 3 can completely cover the slope surface, the edge of the flap 3 is hinged to the low point of the slope surface, the inner wall of the feed pipe 1 has a fixed block 5, and the upper end of the sleeve rod 6 is fixed to the fixed block 5, the upper end of the linkage rod 7 is located in the sleeve rod 6, and the lower end is hinged with the flap 3 at the high point of the slope surface; there is a spring 8 in the sleeve rod 6, and the two ends of the spring 8 are respectively fixed on the top of the sleeve rod 6 And the upper end of linkage rod 7.

[0013] When the biomass granular material enters the flap 3 through the feed pipe 1, it overcomes the resistance of the spring 8 under the action of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com