Dry sterilizer based on flow guide speed increment

A drying sterilization and speed technology, which is applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of inconvenient cleaning and poor sterilization effect of the heating device, so as to improve the drying and sterilization effect and improve the drying effect. The effect of uniformity and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

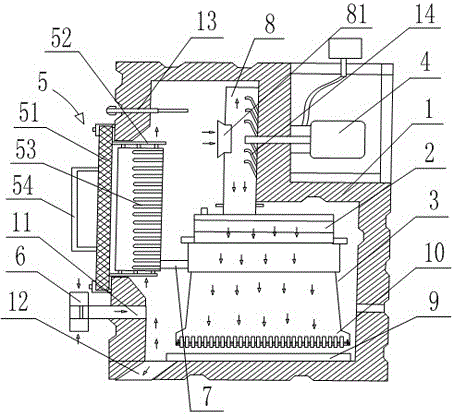

[0046] Such asfigure 1 , figure 2 As shown, the drying and sterilizing device based on increasing the diversion velocity includes a housing 1, which is provided with an air inlet 11 and an air outlet 12, and a conveying mechanism 9 is provided under the inside of the housing 1. A heating device 5 is arranged above the tuyeres 11, an air gathering tube 8 is arranged inside the housing 1, and an air inlet 81 cooperating with the heating device 5 is provided on the side wall of the housing 1. Cooperating heating laminar flow fan 4, the lower end of described air gathering tube 8 is provided with second filter 2, and the wind outlet end of second filter 2 is connected with gathering wind hood 3, and the wind outlet end of gathering wind cover 3 is connected with conveying The mechanism 9 cooperates; the heating device 5 includes a support plate 51, the inner wall of the support plate 51 is symmetrically provided with two fixed plates 52, the inner side of the fixed plate 52 is pr...

Embodiment 2

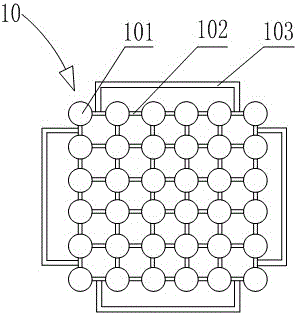

[0048] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the air inlet 11 is provided with a first filter 6; the housing 1 is provided with a temperature sensing device 13 at the air outlet of the heating device 5, and the temperature sensing Device 13 is a temperature sensor, and can also be a thermocouple; a baffle plate 7 is arranged between the heating device 5 and the wind gathering hood 3; the inner diameter of the wind gathering tube 8 is less than the inner diameter of the wind gathering hood 3; The outer wall of 51 is provided with a handle 54; the inner diameter of the exhaust pipe 101 is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com