Method and system for testing sliding resistance of pure electric vehicles

A sliding resistance and pure electric drive technology, which is applied in vehicle testing, machine/structural component testing, force/torque/power measuring instruments, etc., can solve the problem that the transmission system distribution and change law cannot be obtained, and the detection parameters can be controlled low sensitivity, difficult to improve the performance of the transmission system, etc., to achieve the effect of safe and controllable test method, easy operation and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

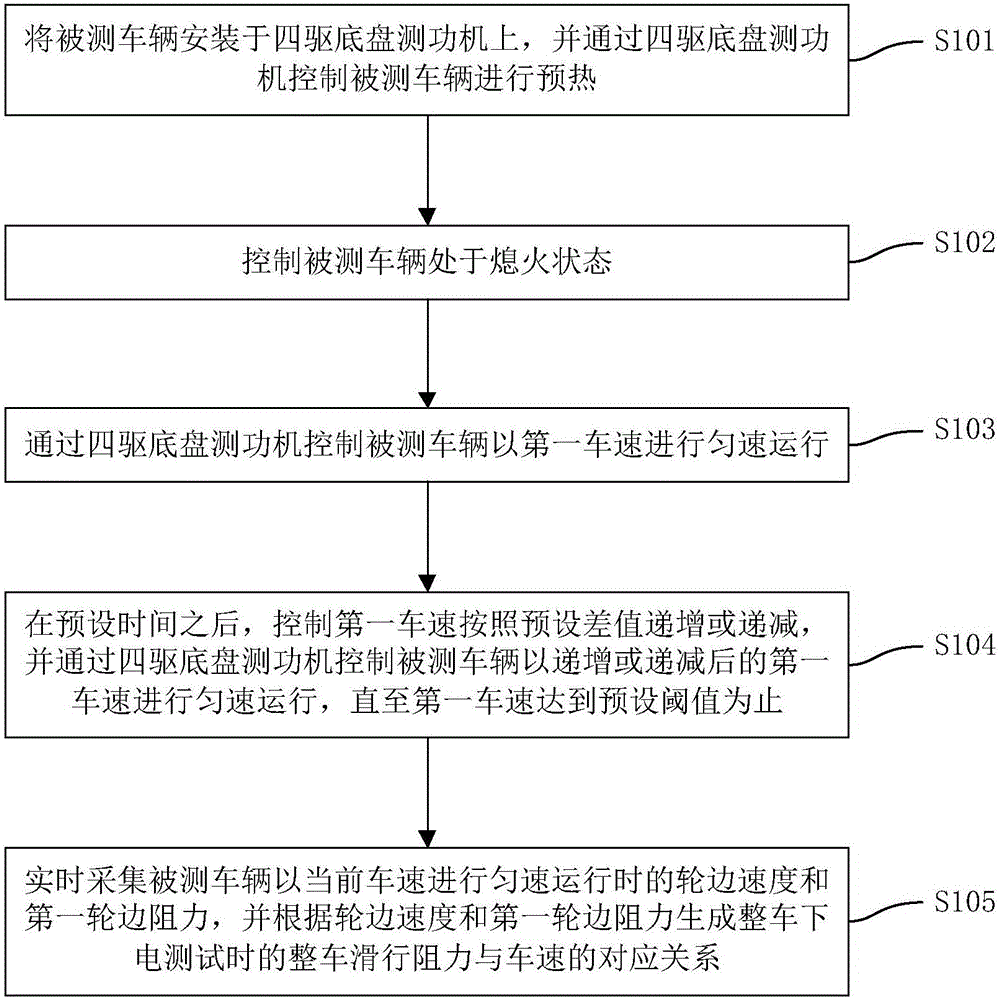

[0019] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0020] The method and system for testing the sliding resistance of a pure electric drive vehicle according to an embodiment of the present invention will be described below with reference to the accompanying drawings.

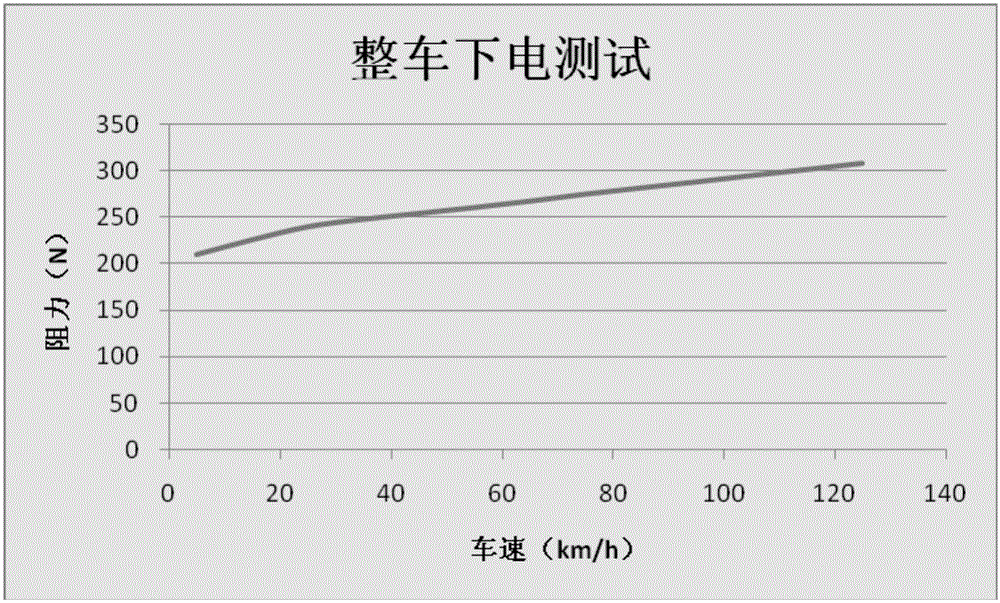

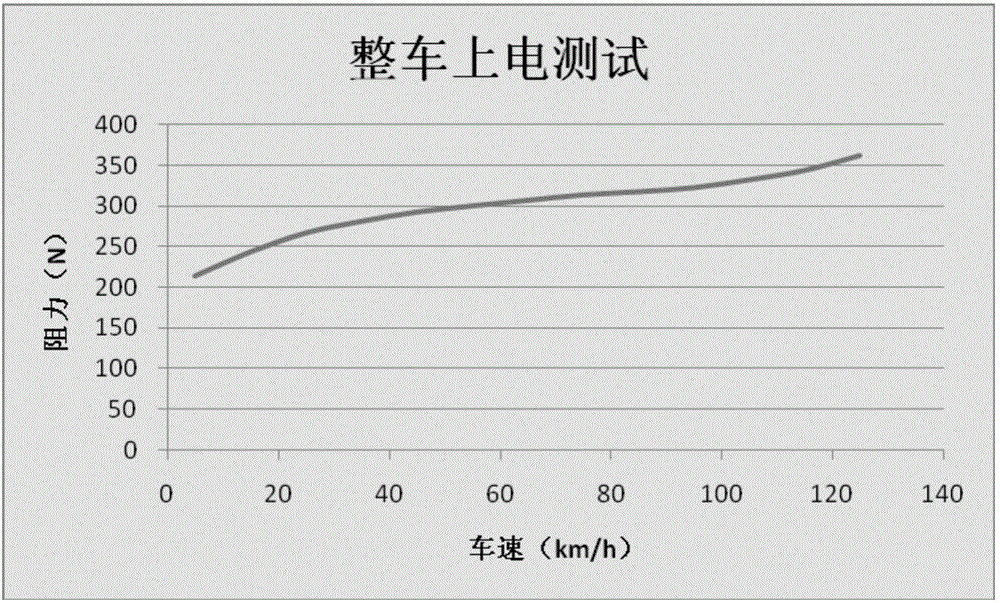

[0021] Because the sliding resistance of pure electric vehicles is very different from that of traditional vehicles, the engine can be disconnected from the transmission during the sliding process of traditional vehicles, while most pure electric vehicles use single-stage reducers. The mechanical connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com