High-temperature containment test technology for aeroengine casing

A high temperature and casing technology, applied in the field of high temperature containment test of aero-engine casing, can solve the problems of easy damage, increased test difficulty, low strength of electric furnace materials, etc., and achieves the effect of strong flexibility and improved reference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples.

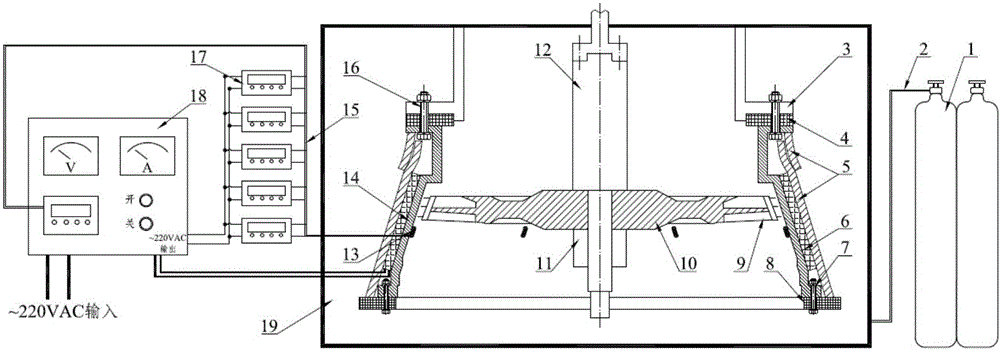

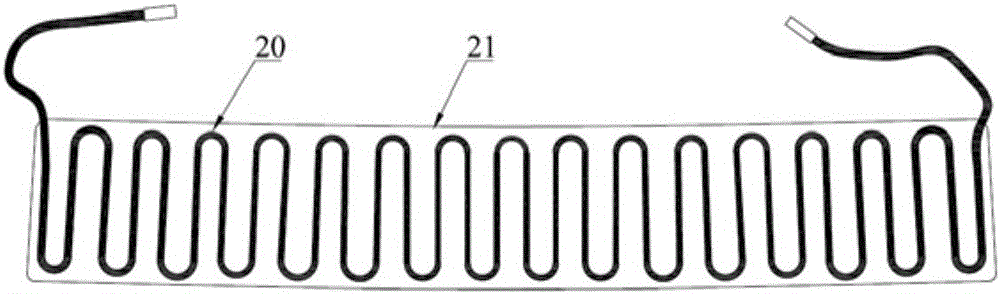

[0029] Such as figure 1 As shown, a casing high-temperature containment test device based on a contact heating method includes a contact electric heater 6, a thermocouple 13, a heating wire and a thermocouple lead wire 15, a temperature control cabinet 18, an upper heat shield 4, a lower partition Hot plate 8, thermal insulation blanket 5, temperature display instrument 17, etc.

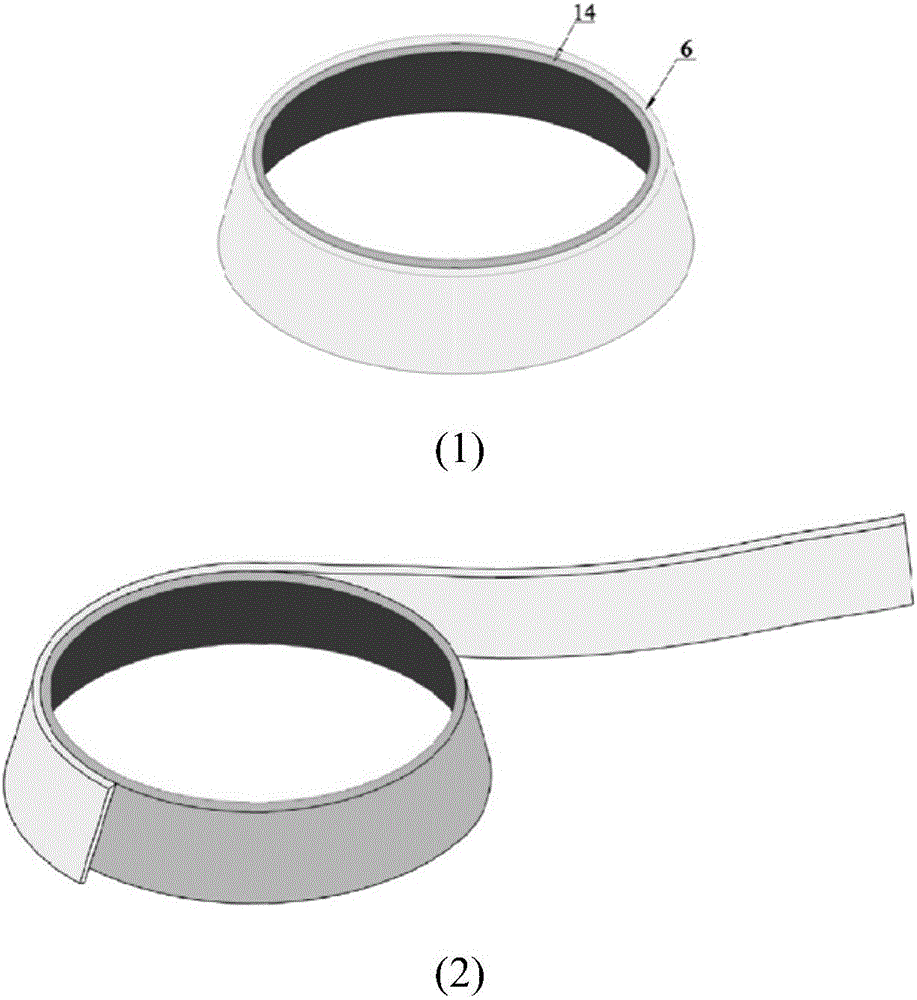

[0030] The case 14 acts as the main body for heating, and the outer wall is wound by the contact electric heater 6 for a circle, and the contact electric heater 6 is connected end to end; the upper heat shield 4 and the lower heat shield 8 are respectively located on the upper and lower installation sides of the case 14 and connected position; thermal insulation felt 5 is wound outside the contact electric heater 6 and according to the thermal insulation requirements and the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com