Intelligent evaluation method and system for supplier steel plate cutting

An evaluation system and supplier technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of low reliability, poor referenceability, and long time consumption of cutting evaluation results, so as to improve detection efficiency and system detection performance. Effectiveness, the effect of narrowing the scope of quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

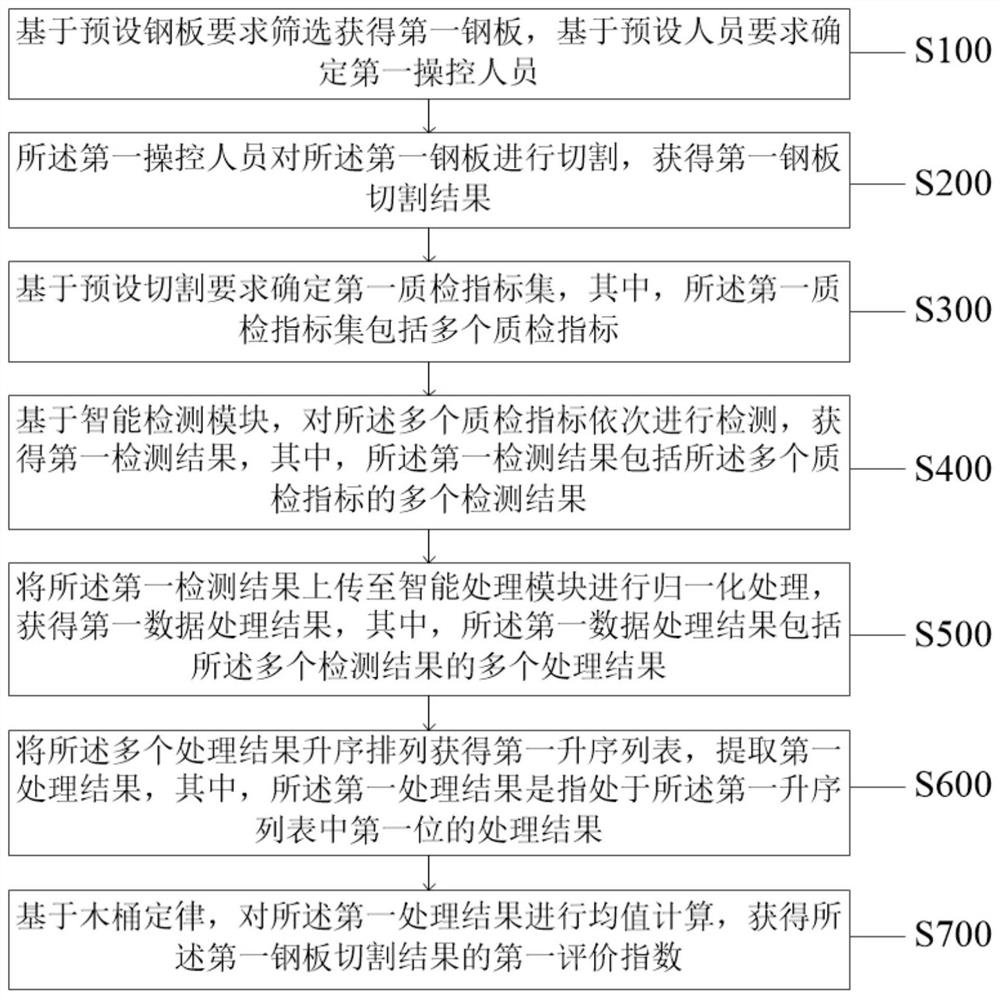

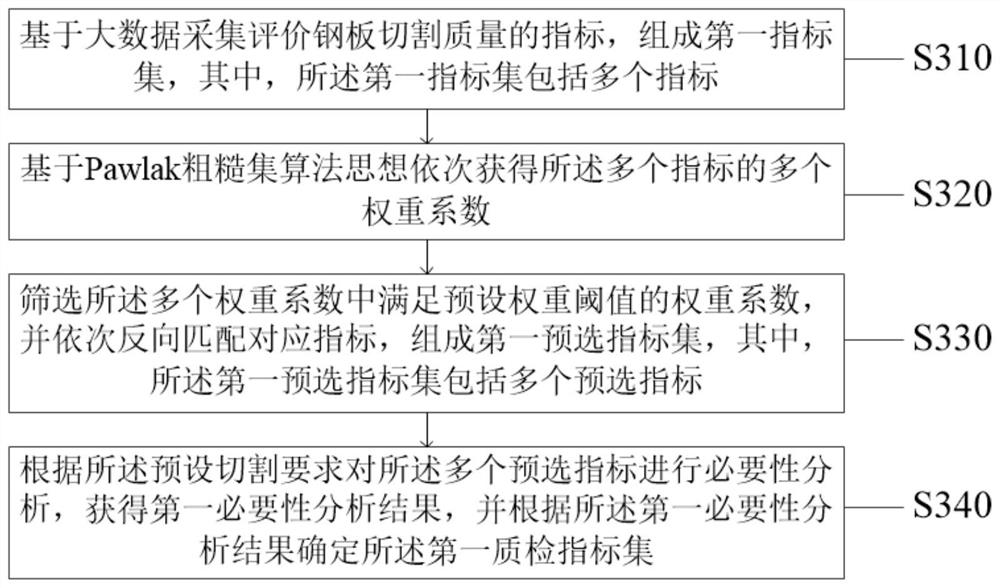

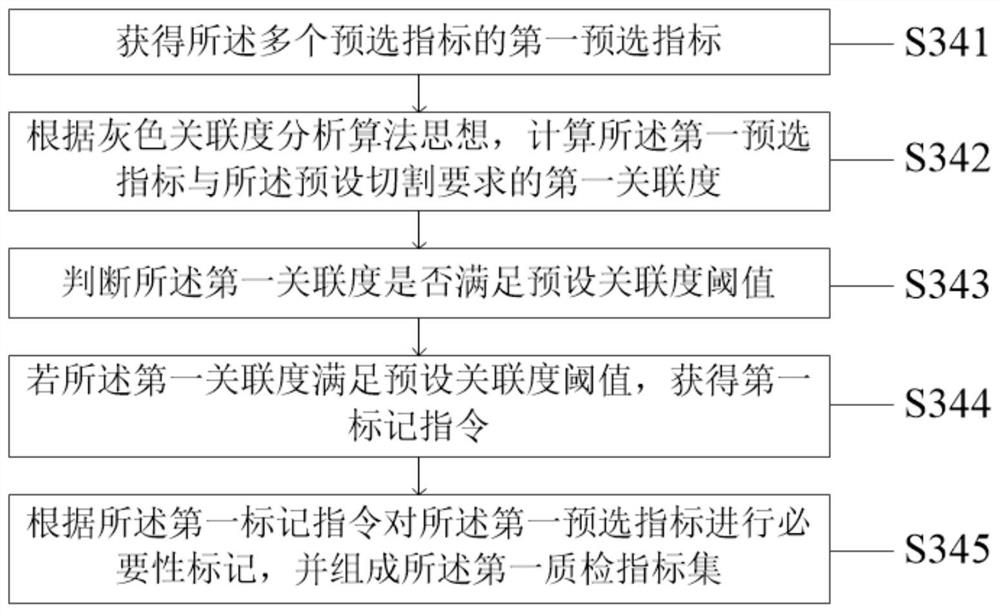

[0032] Please see attached figure 1 , The present invention provides an intelligent evaluation method for supplier steel plate cutting, wherein, the method is applied to an intelligent evaluation system for supplier steel plate cutting, and the method specifically includes the following steps:

[0033] Step S100: screening and obtaining a first steel plate based on a preset steel plate requirement, and determining a first operator based on a preset personnel requirement;

[0034] Specifically, the application of the intelligent evaluation method for supplier steel plate cutting to the intelligent evaluation system for supplier steel plate cutting can be consistent by controlling other variable factors other than the steel plate cutting itself that affect the cutting quality, and only Intuitive quantitative evaluation of the steel plate cutting effect itself.

[0035] Wherein, the preset steel plate requirements refer to the basic quality requirements of the steel plates to be...

Embodiment 2

[0108] Based on the same inventive concept as an intelligent evaluation method for supplier steel plate cutting in the foregoing embodiment, the present invention also provides an intelligent evaluation system for supplier steel plate cutting, please refer to the appendix Figure 5 , the system includes:

[0109] a first obtaining unit 11, the first obtaining unit 11 is configured to screen and obtain a first steel plate based on a preset steel plate requirement, and determine a first operator based on a preset personnel requirement;

[0110] The second obtaining unit 12, the second obtaining unit 12 is used for the first operator to cut the first steel plate to obtain the cutting result of the first steel plate;

[0111] a first determination unit 13, the first determination unit 13 is configured to determine a first quality inspection index set based on preset cutting requirements, wherein the first quality inspection index set includes a plurality of quality inspection indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com