Frameless liquid crystal module structure

A liquid crystal module, frameless technology, used in nonlinear optics, instruments, optics, etc., can solve the problems of poor appearance integrity, O/C degumming, etc., to achieve the effect of good integrity, simple and neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described below by accompanying drawing.

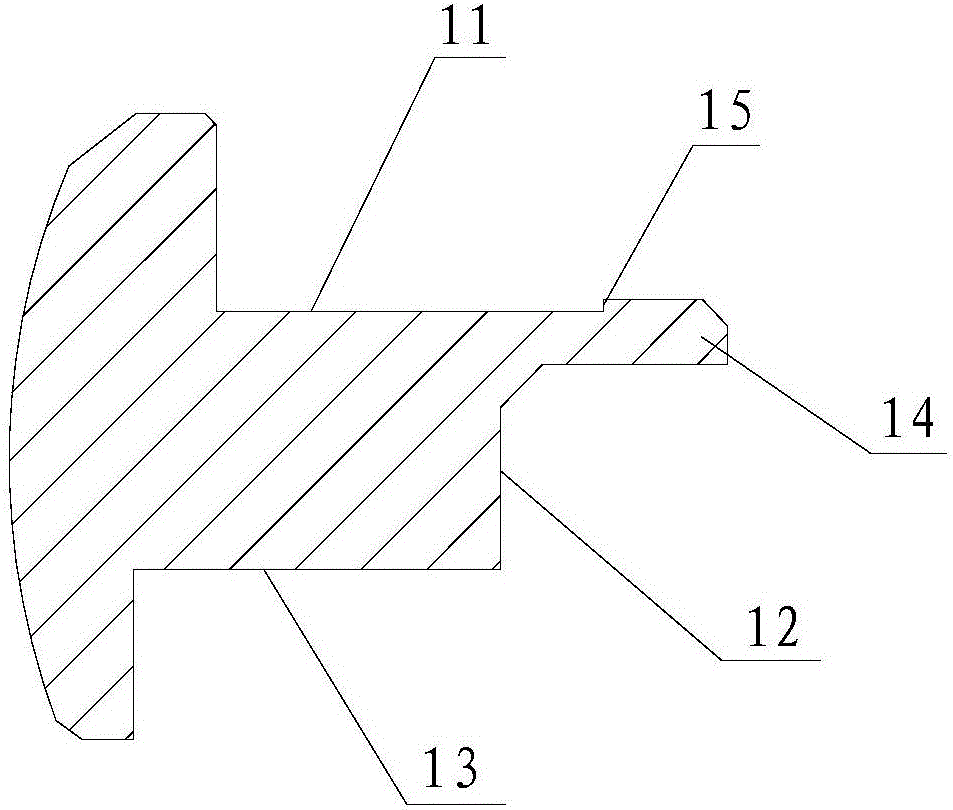

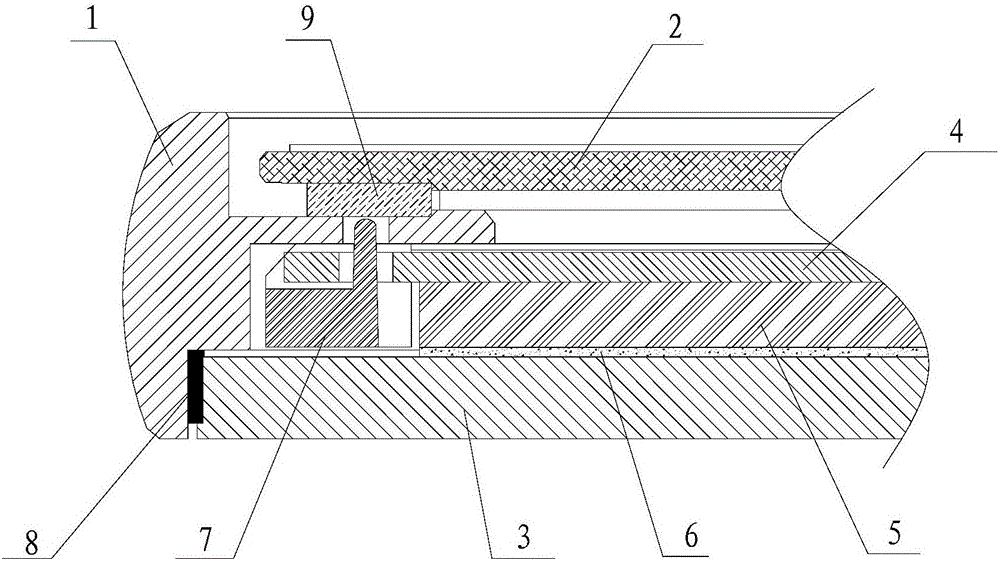

[0017] Such as figure 1 , figure 2 As shown, the present invention includes an aluminum profile surface frame 1 and a liquid crystal glass panel 2 installed in the aluminum profile surface frame 1, a reflective paper 6, a light guide plate 5 and a film 4, and the section of the aluminum profile surface frame 1 is provided with three The last step is the back plate step 13, which is used to locate the back plate 3, and the middle step is the diaphragm step 12, which is used to place the reflective paper 6, the light guide plate 5 and the diaphragm 4, and the diaphragm step 12 is higher than the back plate step 13, and the frontmost step is the panel step 11, which is used to place the liquid crystal glass surface 2. The panel step 11 is lower than the diaphragm step 12, and a partition is provided between the panel step 11 and the diaphragm step 12 The bar 14 is used to separate the liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com