Quantum dot film and backlight module

A quantum dot film and film technology, applied in optics, optical elements, nonlinear optics, etc., can solve the problems of low backlight utilization, excitation light loss, loss, etc., and achieve the effect of improving backlight utilization and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

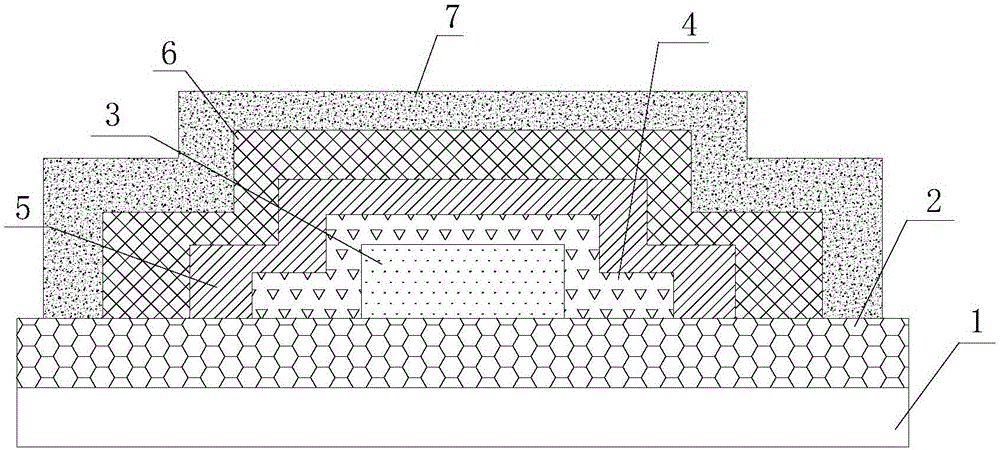

[0026] Implementation mode one: if figure 1 As shown, a quantum dot film includes in turn: a substrate layer 1, a buffer layer 2, a quantum dot layer 3, a protective layer 4, a water and oxygen barrier layer 5, a hardening layer 6, and a first anti-reflection layer 7; An antireflection layer 7 is antireflective to white light. The buffer layer 2 is equivalent to a layer of adhesive, which is used to bond and fix the quantum dot layer 3 and the substrate layer 1 , so as to increase the peeling force between the quantum dot layer 3 and the substrate layer 1 . The protection layer 4 is formed on the quantum dot layer 3 and encapsulates the quantum dot layer 3, so that all parts of the quantum dot layer 3 can be well protected. This is because the structure of the quantum dot layer 3 is unstable, so the protective layer 4 needs to be formed immediately after film formation for pre-protection. Apparently, the protection layer 4 is formed with materials capable of protecting the s...

Embodiment approach 2

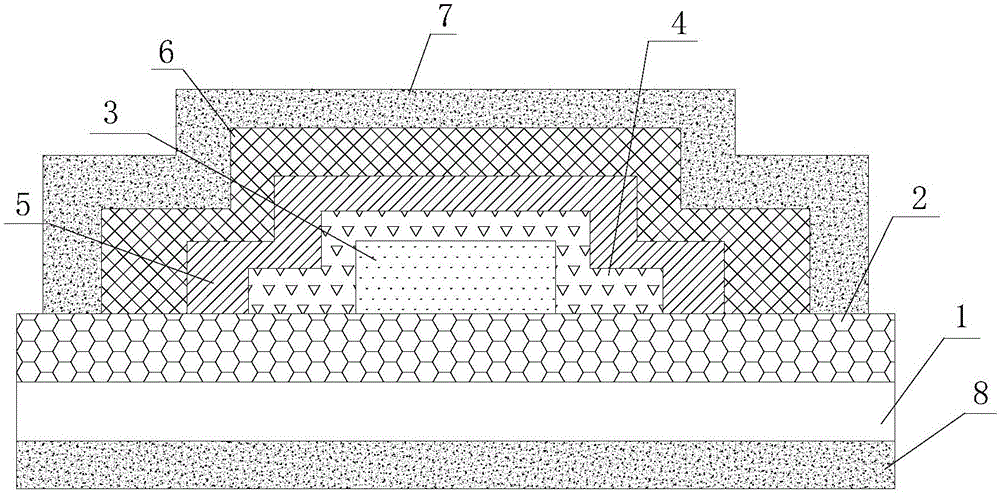

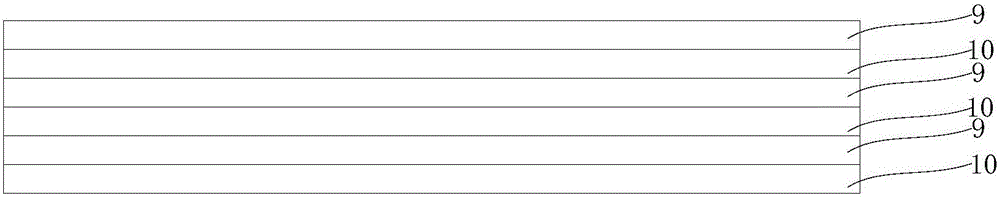

[0029] Implementation mode two: if figure 2 As shown, the quantum dot film includes a second anti-reflection layer 8, the second anti-reflection layer is disposed on the surface of the substrate layer not facing the buffer layer, and the second anti-reflection layer is anti-reflective to white light. The second anti-reflection layer is composed of six anti-reflection film layers, and the structure of the second anti-reflection layer is the same as that of the first anti-reflection layer. The light transmittance is also the same.

[0030] The present invention also provides a backlight module, the backlight module includes a quantum dot film, the quantum dot film is made by the above solution of this embodiment, and other structures of the backlight module adopt the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com