Filter capacitor fixing device

A technology for fixing devices and filter capacitors, which is applied in the direction of capacitors and electrical components, and can solve problems such as space position restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

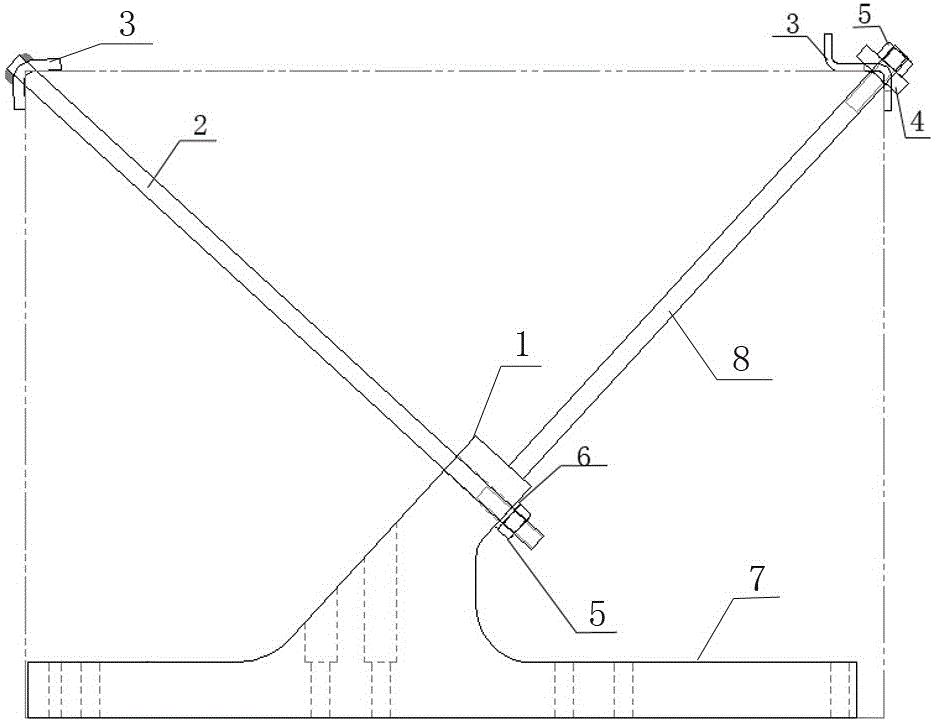

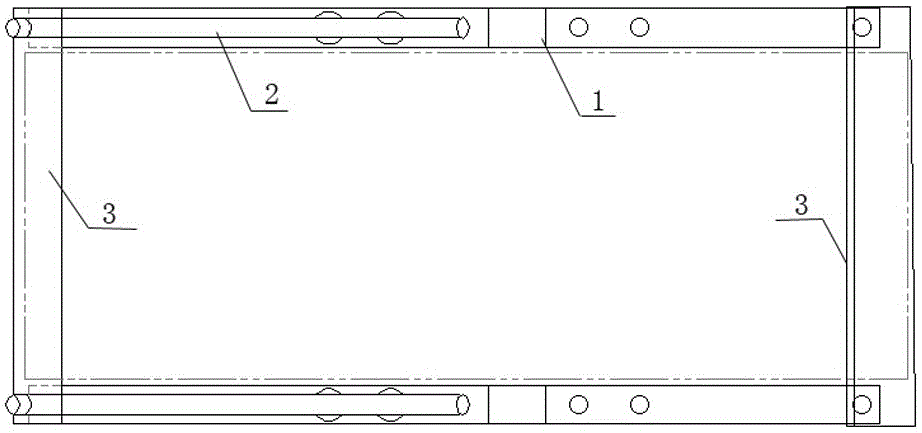

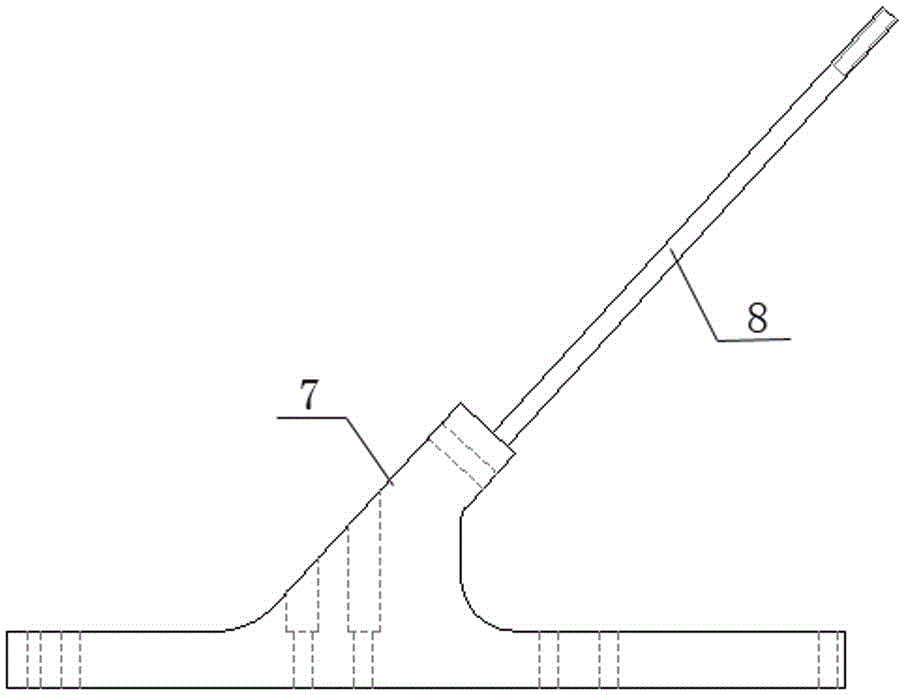

[0016] A filter capacitor fixing device, comprising a capacitor support 2 and a pair of capacitor fixing frames 1, the capacitor fixing frame 1 includes a fixing frame base 7 and an oblique pull rod 8 arranged on the fixing frame base, and the oblique pull rods on the two capacitor fixing frames The free ends of 8 are connected with a bending plate 3 that is bent at 90 degrees in the middle, and the free end of the oblique pull rod 8 is also provided with a pressing plate 4 and is pressed and fixed on the bending place of the bending plate by a nut 5. The inclination angle and length of the pull rod 8 are set according to the rectangular capacitor to be fixed, so that the free end of the oblique pull rod is located at an arc corner on the top surface of the rectangular capacitor, and the front and rear ends of the two fixed mount bases 7 A front fixing plate and a rear fixing plate are respectively connected between them. The capacitor support 2 includes two rods arranged in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com