A kind of superjunction mosfet structure and preparation method thereof

A silicon substrate, heavy doping technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor stability and complicated preparation process of super-junction MOSFETs, achieve small on-resistance and reduce manufacturing costs. cost, and the effect of improving breakdown resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

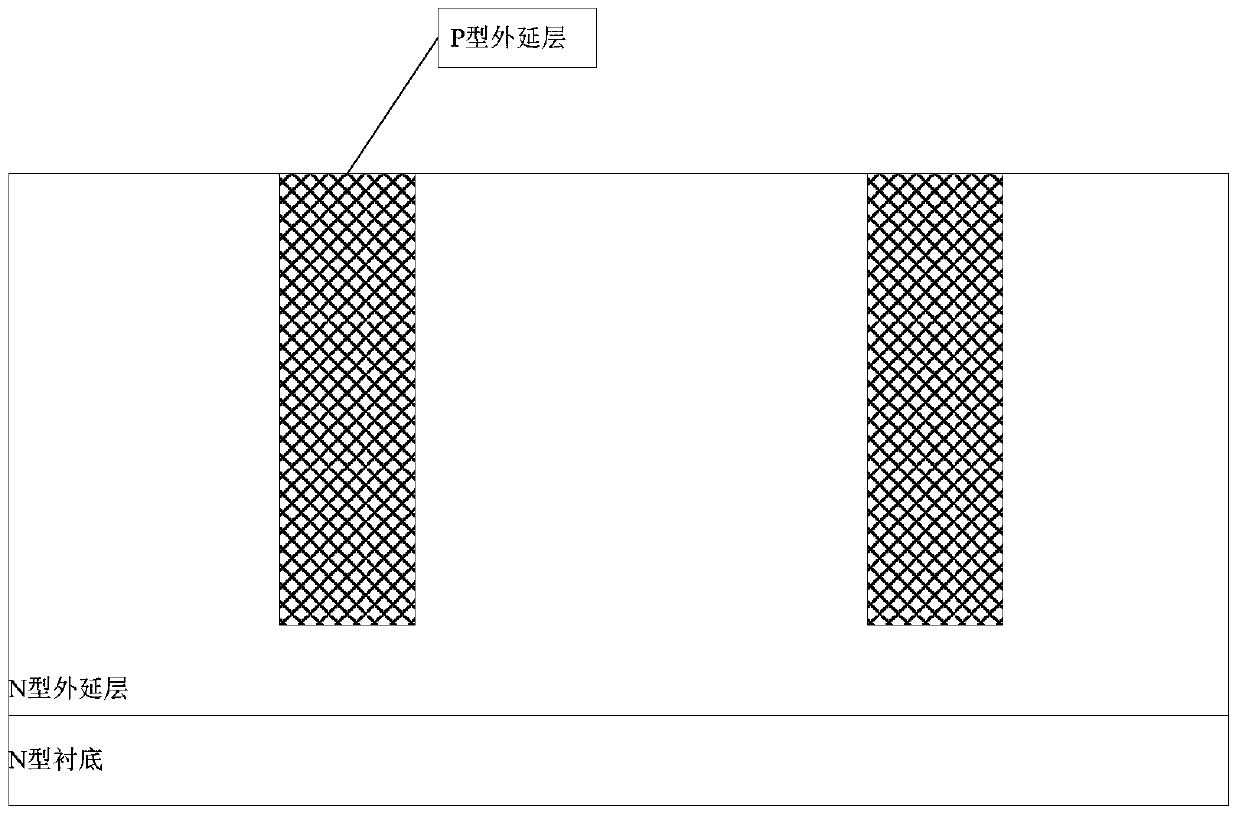

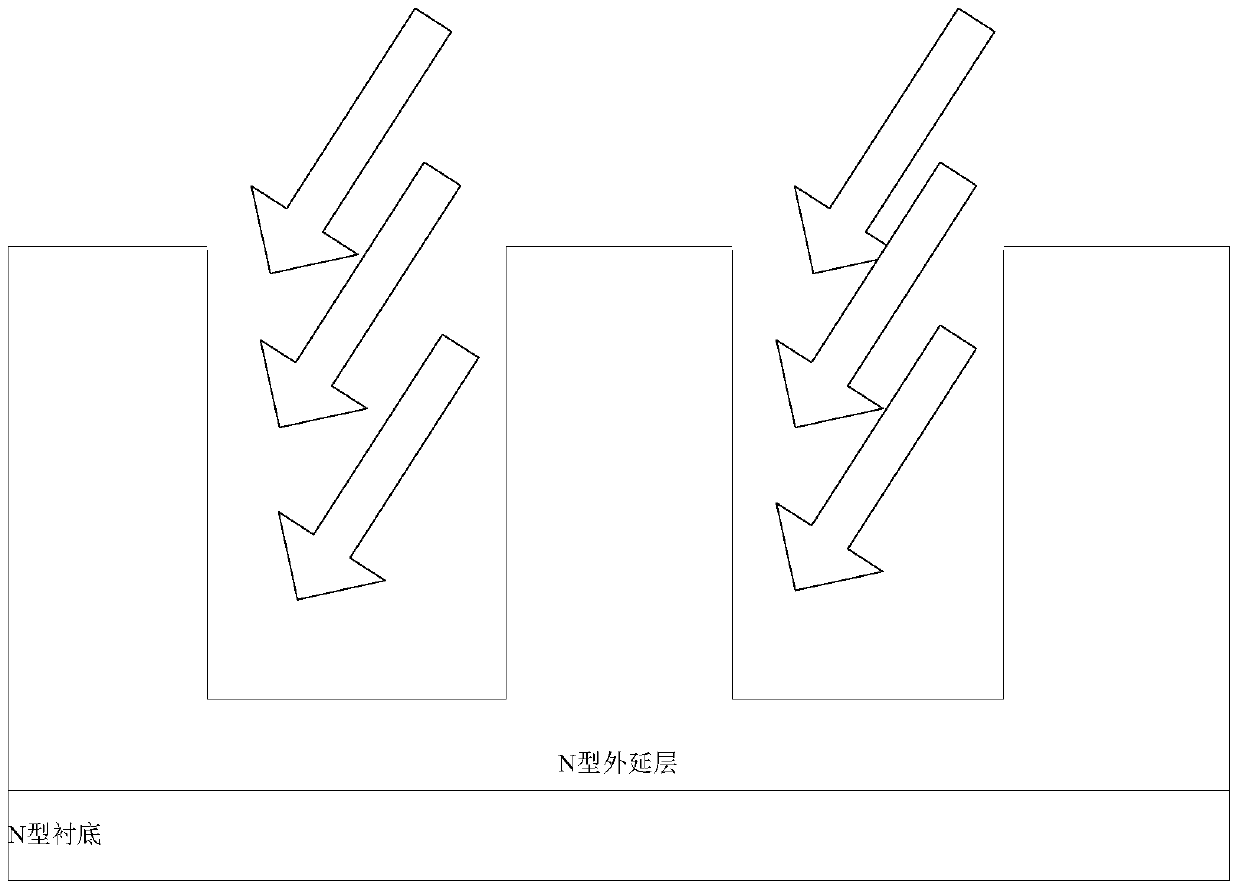

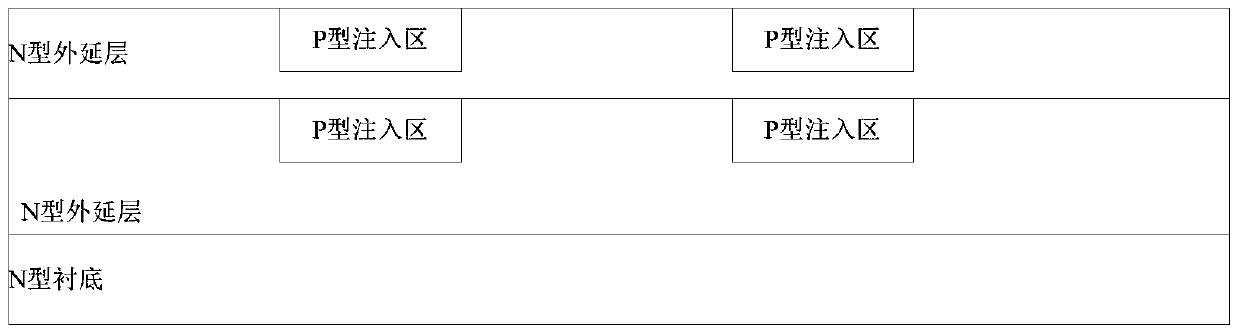

[0066] In order to save energy and reduce the power loss of the transistor, the on-resistance of the transistor should be reduced as much as possible; but because the breakdown voltage is proportional to the on-resistance, in order to solve this problem, a super-junction transistor, namely a super-junction MOSFET, is introduced. In order to improve the breakdown resistance characteristics of the device. Such as Figure 4 As shown, the embodiment of the present invention provides a super junction MOSFET structure, which specifically includes: a silicon substrate 1, a thick oxygen region 2, a diffusion column 3, a source region 4, a silicon body region 5, a gate oxide polycrystalline layer 6, a dielectric Layer 7 and metal layer 8. in,

[0067] A plurality of grooves are opened on the silicon substrate 1, and a thick oxygen region 2 is formed in the groove, and a diffusion column 3 is formed between the thick oxygen region 2 and the inner wall of the groove, and the doping typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com