Electric heating tube applicable to liquid-phase heat conduction medium

A technology of electric heating tube and heat conduction medium, which is applied in the direction of ohmic resistance heating, ohmic resistance heating parts, heating element materials, etc., which can solve problems such as corrosion and metal leakage, and prevent leakage, excessive temperature and leakage liquid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following specific embodiments are used to illustrate the present invention, but are not used to limit the scope of the present invention.

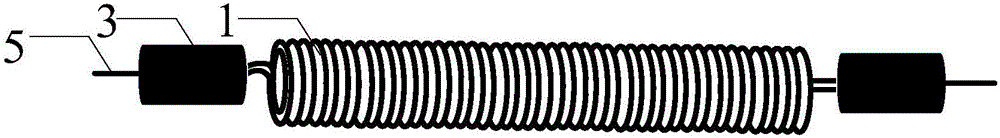

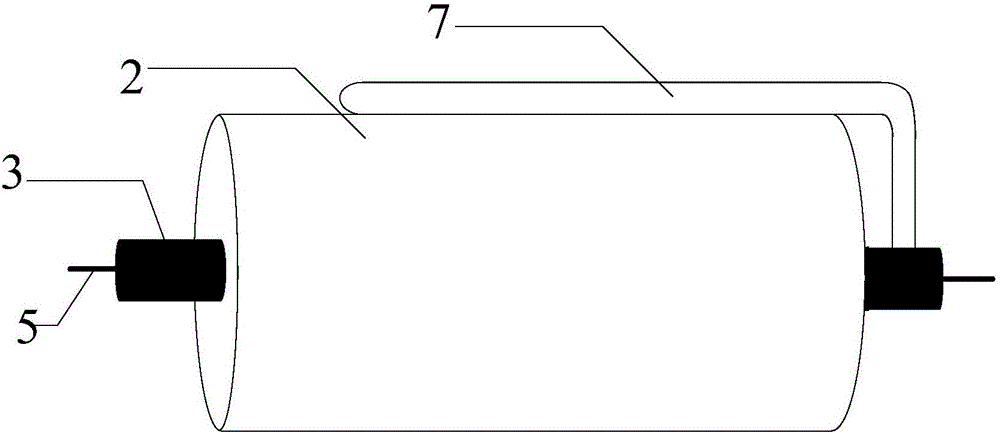

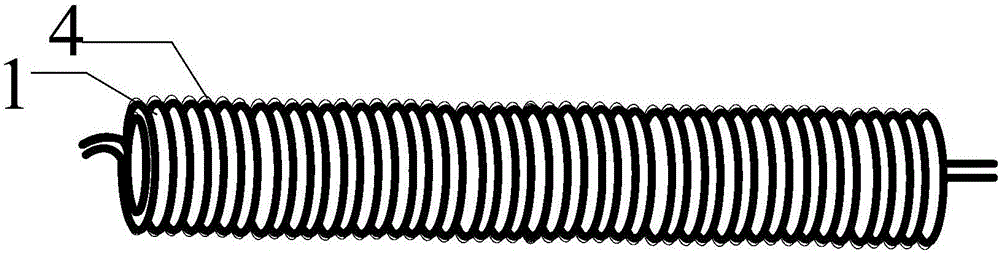

[0024] Such as Figure 1-2 As shown, the present invention provides an electric heating tube suitable for a liquid-phase heat-conducting medium. The electric heating tube includes a spiral heating wire 1, a metal shell 2, and a wire electrically connected to both ends of the electric heating wire 1. 5 and a cylindrical sealed insulating shell 3 that surrounds the junction of the wire 5 and the heating wire 1; the heating wire 1 is located in the metal tube shell 2, and part of the sealed insulating shell 3 is located in the metal In the tube shell 2, the other part is located outside the tube shell 2, and the metal tube shell 2 is hermetically connected to the sealed insulating shell 3; a containing liquid is formed between the inner wall of the metal tube shell 2 and the heating wire 1 The cavity of the same heat-conducting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com