Powder mixing and stirring device

A technology of mixing and stirring powder, which is applied in the direction of mixers, mixing methods, mixers with rotating containers, etc., can solve the problems of powder sticking together or sticking to the inner wall of the mixing device, and prevent Powder adhesion, damage prevention, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

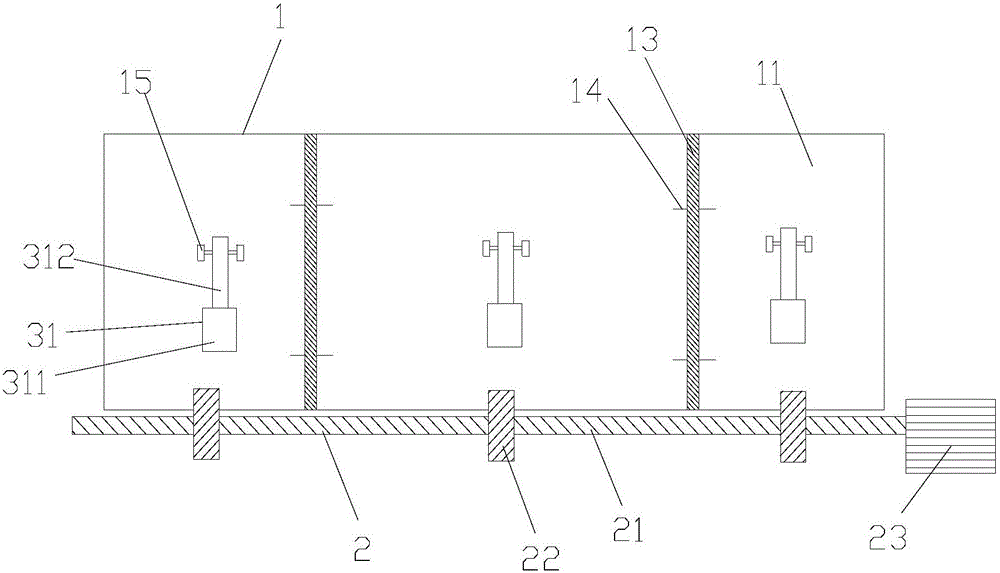

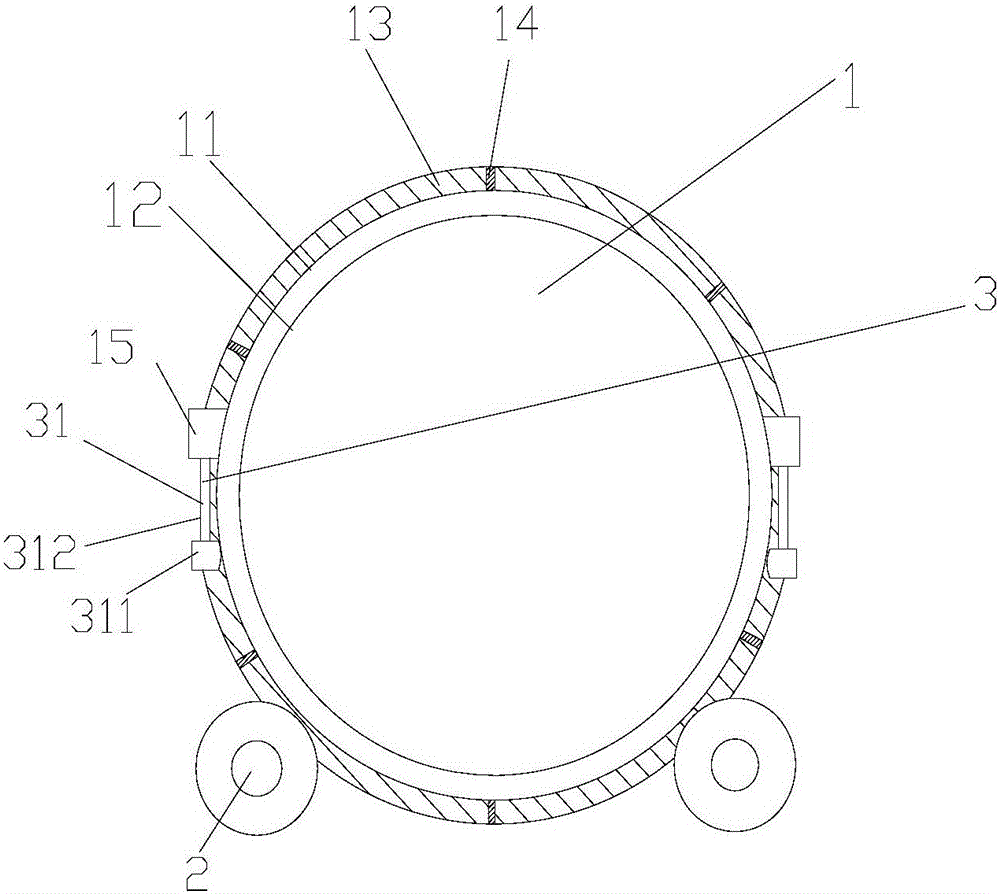

[0018] Such as figure 1 , figure 2 As shown, a powder mixing and stirring device includes a cylinder 1 placed horizontally. The left and right sides of the cylinder 1 are open. The outer circular surface 11 is in contact, the inner wall of the cylinder 1 is provided with a corrosion-resistant layer 12, and the outer circular surface 11 of the cylinder 1 is provided with several groups of striking devices 3, and the striking device 3 includes two symmetrically arranged outer circular surfaces. The striking hammer 31 on 11 is movably connected on the outer circular surface 11, and the striking hammer 31 is perpendicular to the axial direction of the cylinder 1.

[0019] In order to increase the stability of the cylinder, several groups of surrounding rings 13 are set on the outer surface 11 of the cylinder 1, and the two sides of the ring 13 are provided with support frames 14 connected to the outer surface 11 of the cylinder 1, and the circle The ring 13 is provided in at le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap