Repair mode for circumferential weld in ladle slag line part

A ladle slag line and ring seam technology, which is applied in the field of iron and steel metallurgical ladle lining repair, can solve the problems of slag line brick waste, heavy workload, and troublesome operation, so as to increase the continuous service life and reduce the consumption of refractory materials per ton of steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

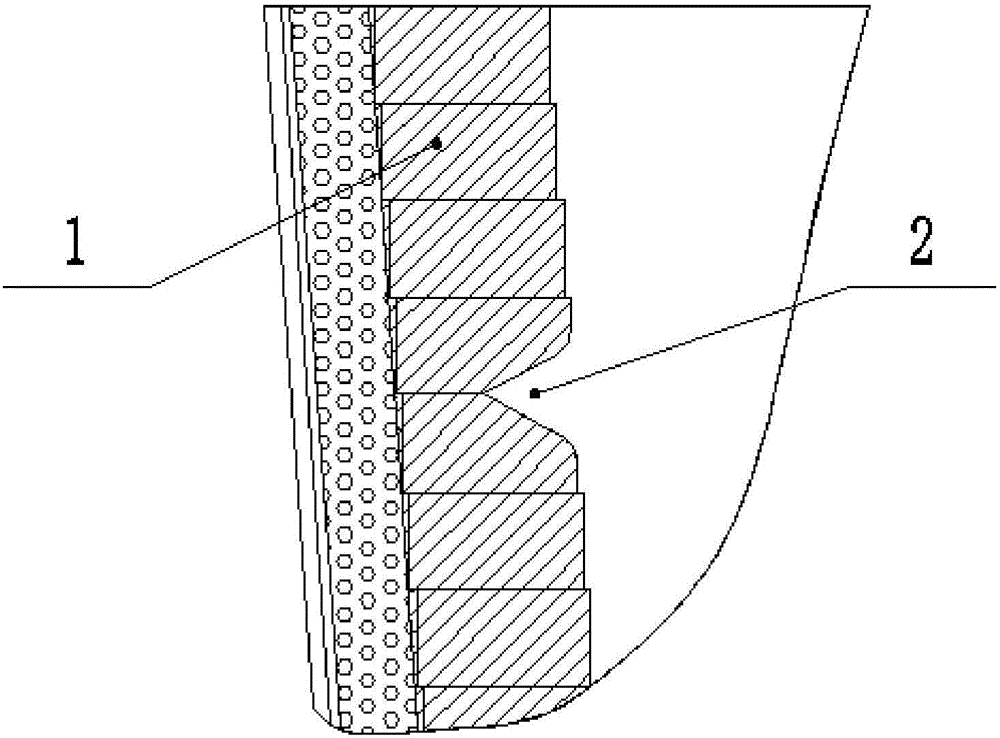

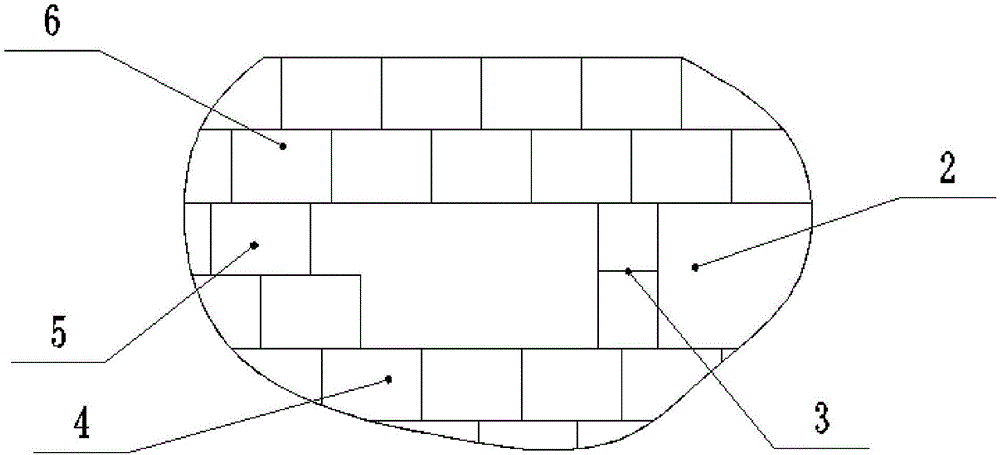

Embodiment 1

[0040] This embodiment is a steel ladle containing 120t cord. The working lining of the ladle slag line uses high-carbon magnesia carbon bricks. The working lining of the ladle wall is low-carbon magnesia carbon bricks. The length of the slag line brick is 200 and the thickness is 100. The length of the brick is 170, the thickness is 100, the size deviation of the ladle brick is ±1mm, the width of the brickwork allowed is not more than 1mm, and the number of furnaces used in this overhaul package is about 35 furnaces. The refining method is mainly LF, and the ladle is available for minor repairs. It is obvious that there is a deep groove at the slag liquid level, and the other parts are good; the minimum residual thickness allowed for the ring joint h=100mm, the specific repair steps are as follows:

[0041] 1) Measure the residual thickness of the slag line brick and the sealing brick on the upper part of the ladle ≥150mm, and the thickness of the thinnest part of the ring seam h...

Embodiment 2

[0049] This embodiment is a 180t plain carbon steel ladle, high-carbon magnesia-carbon bricks are used for the working lining of the ladle slag line, and the working lining of the ladle wall is aluminum-magnesia carbon bricks. The length of the slag line brick is 230 and the thickness is 100. The length of 200, the thickness of 100, the size deviation of the ladle bricks is ±1mm, the width of the bricks allowed for masonry is not more than 1mm, and the number of furnaces used in this overhaul package is about 40 furnaces, the refining method is mainly based on LF, and the minor repair of the ladle can be obvious It can be seen that there is a deep groove at the slag liquid level, and the other parts are all good; the minimum residual thickness allowed for the annular joint h=120mm, the specific repair steps are as follows:

[0050] 1) Measure the residual thickness of the slag line brick and the sealing brick on the upper part of the ladle ≥150mm, and the thickness of the thinnest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com