Cutting angle acquiring method for restraining milling burr of carbon fiber laminate

A technology of cutting angle and carbon fiber layer, which is applied in the field of milling of carbon fiber laminate composite materials, to achieve the effect of avoiding burrs and reducing the length of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

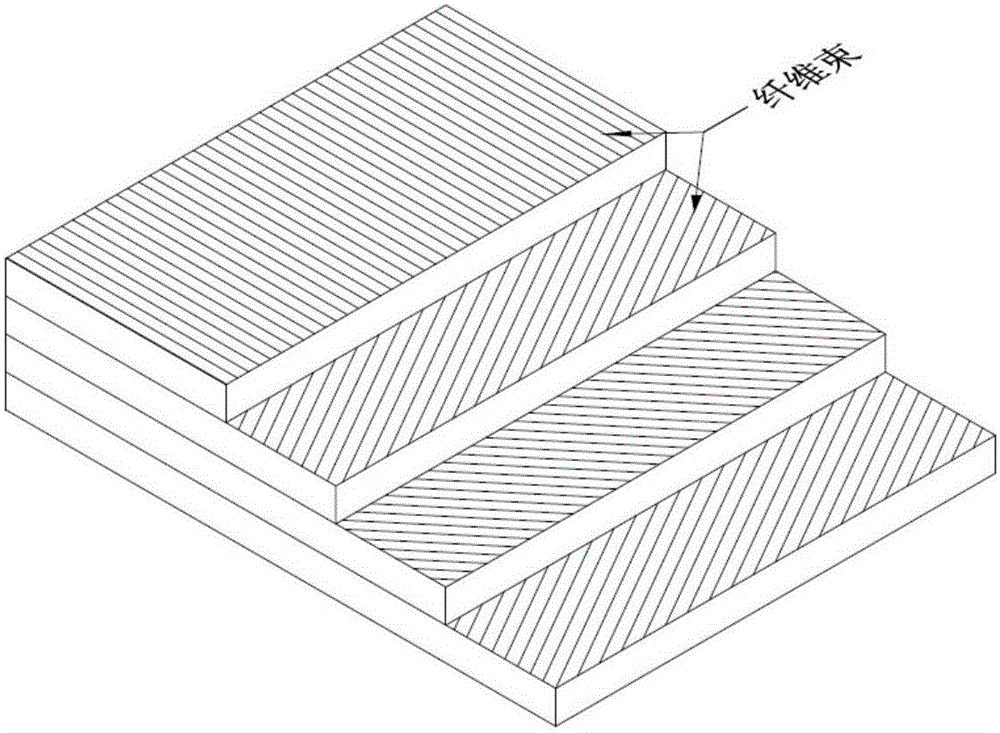

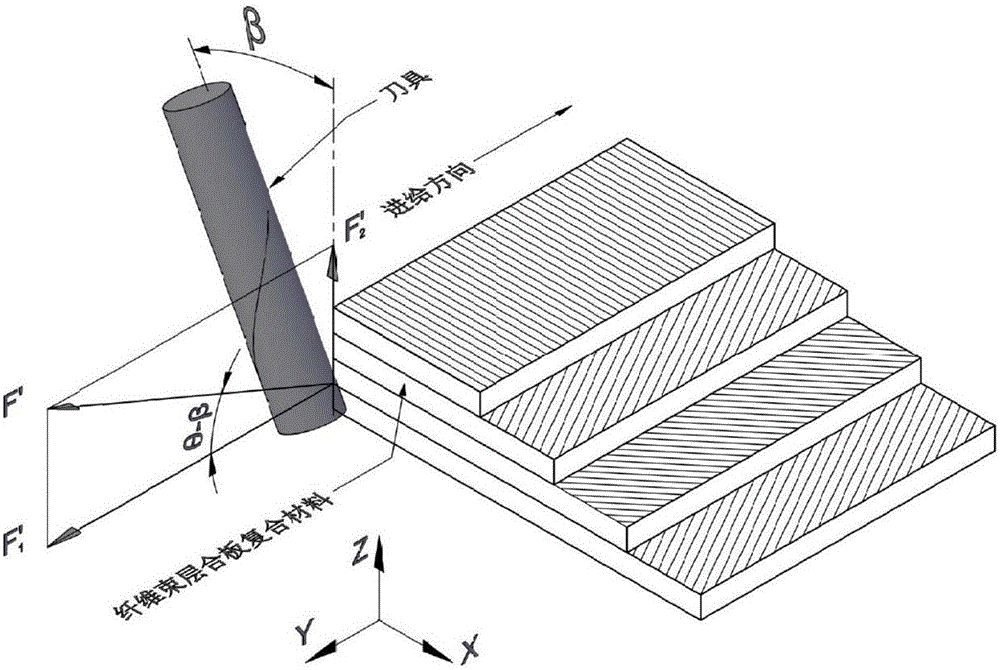

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The method of the present invention includes constructing a relationship model between milling burrs and cutting force angles, and calculating the cutting angle at which the cutting force is parallel to the carbon fiber layer. Carbon fiber laminates are made of multi-layer prepregs laminated according to different fiber directions. The prepregs are composited by reinforcing material carbon fiber and matrix material resin. Its structure is as follows: figure 1 shown.

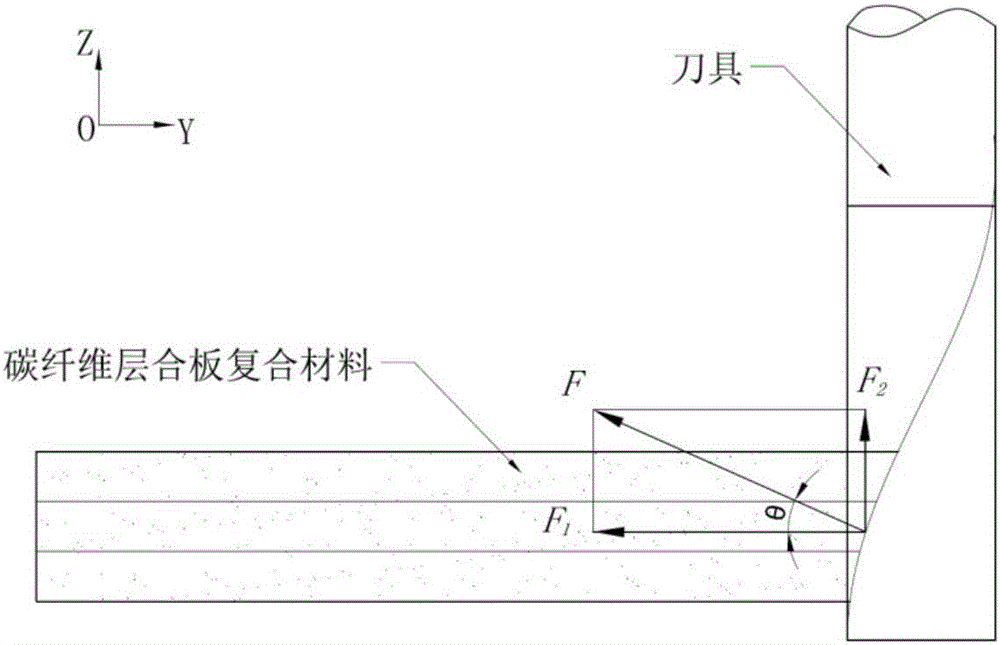

[0023] The milling process of carbon fiber laminates is as follows: figure 2 shown. It can be seen that due to the relationship between the helix angle of the cutter itself, when the cutter teeth cut the material, the milling force on the material is F, and its direction is perpendicular to the rake face of the cutter tooth, which can be decomposed into F along the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com