Laser welding optimization method based on laser induced plasma spectroscopy and device thereof

A plasma spectroscopy and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of plasma spectrum signal correlation, difficult spectral data comparison and analysis, etc., to improve laser welding quality, signal Good quality, flexible adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

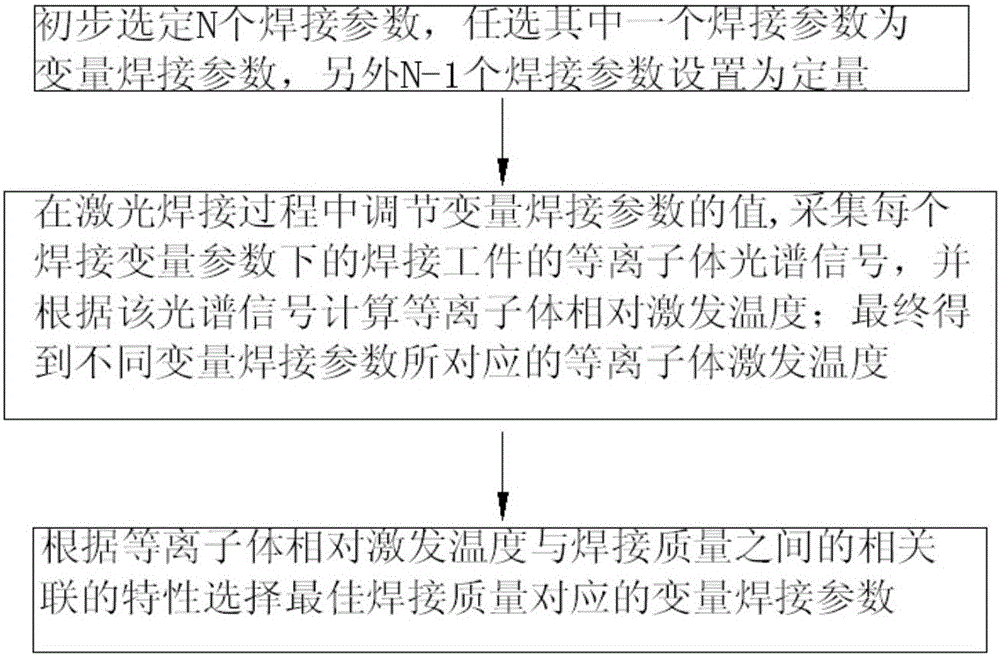

[0052] Such as figure 1 As shown, the laser welding optimization method based on laser-induced plasma spectroscopy in this embodiment includes the following steps:

[0053] S1. Preliminarily set N welding parameters, select one of them as a variable welding parameter, and set N-1 welding parameters as quantitative welding parameters, and N is a natural number above 2;

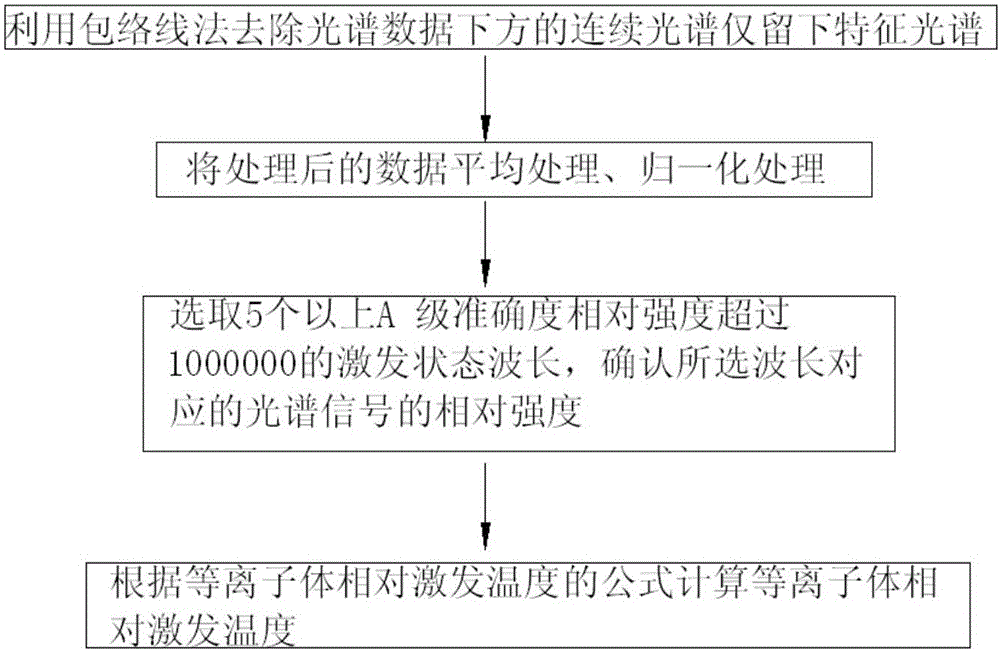

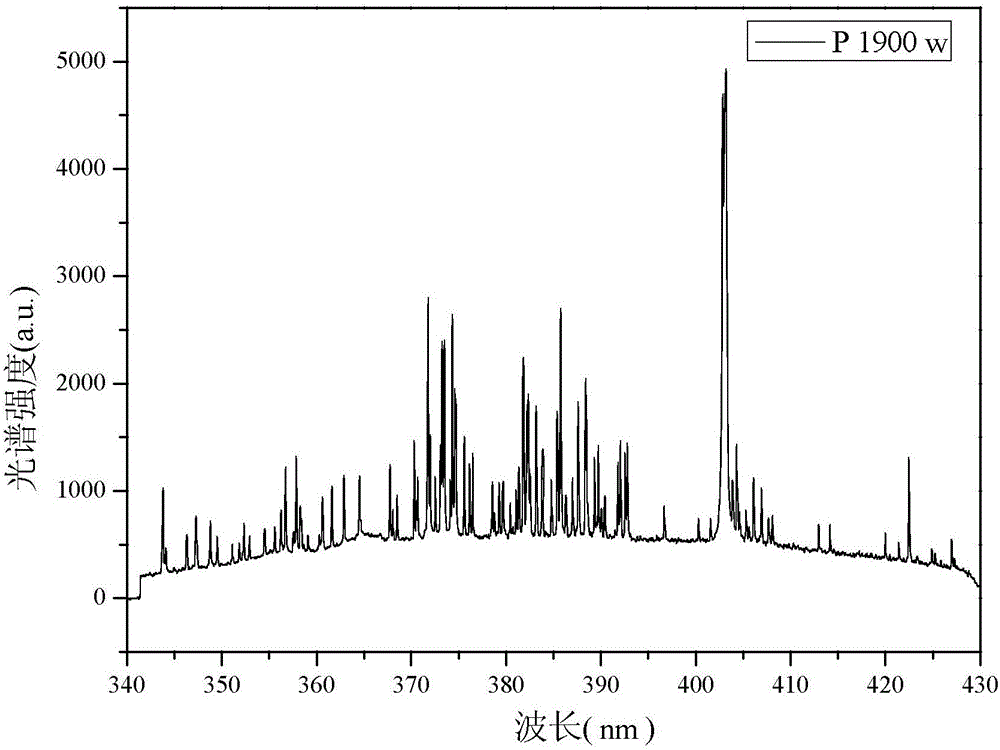

[0054] S2. Start to carry out laser welding on the welding workpiece 1. During the laser welding process, adjust the value of the variable welding parameter in step S1; collect the plasma spectral signal of the welding workpiece 1 during the laser welding process under each variable welding parameter, and according to The relative plasma excitation temperature is calculated from the plasma spectral signal; finally, the plasma relative excitation temperature correspond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com