Roller type cold rolled sheet dislocation and location machanism

A cold-rolled sheet and roller-type technology is applied in the field of pre-welding dislocation positioning devices for butt-jointed cold-rolled sheets, which can solve the problem that the butt-jointed cold-rolled sheets cannot be positioned and conveyed continuously, and achieves improved laser welding quality, reasonable design and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

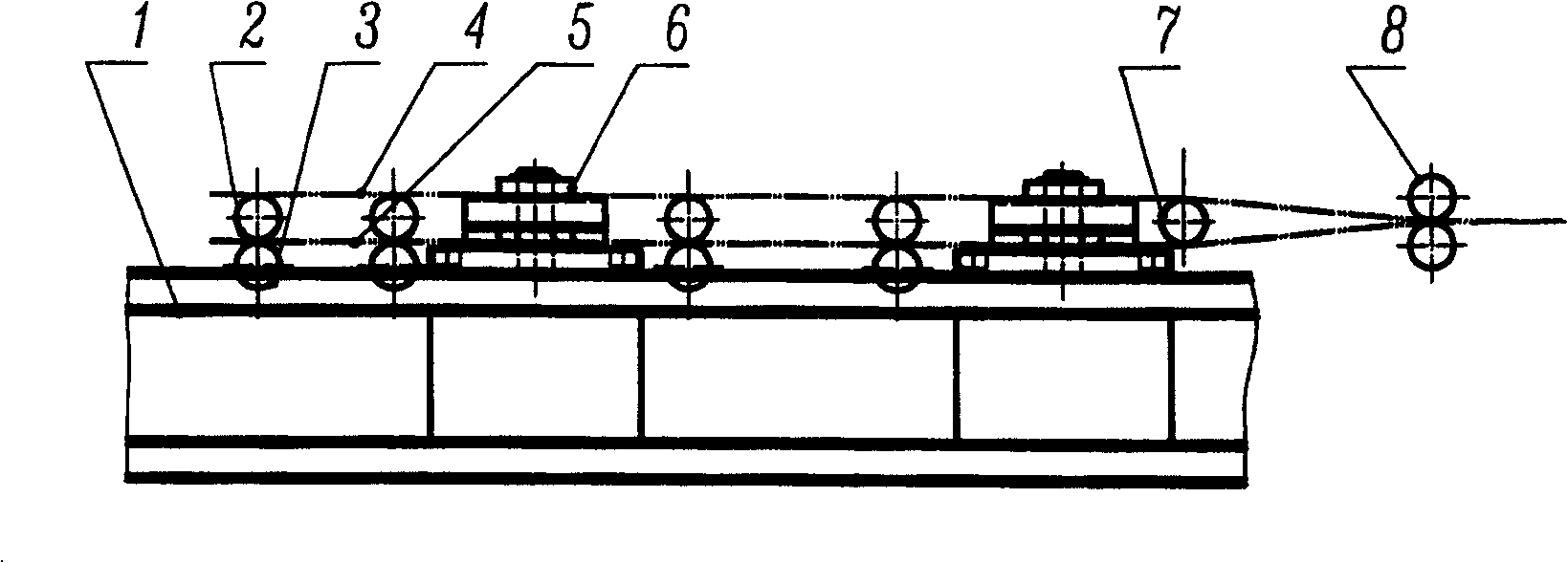

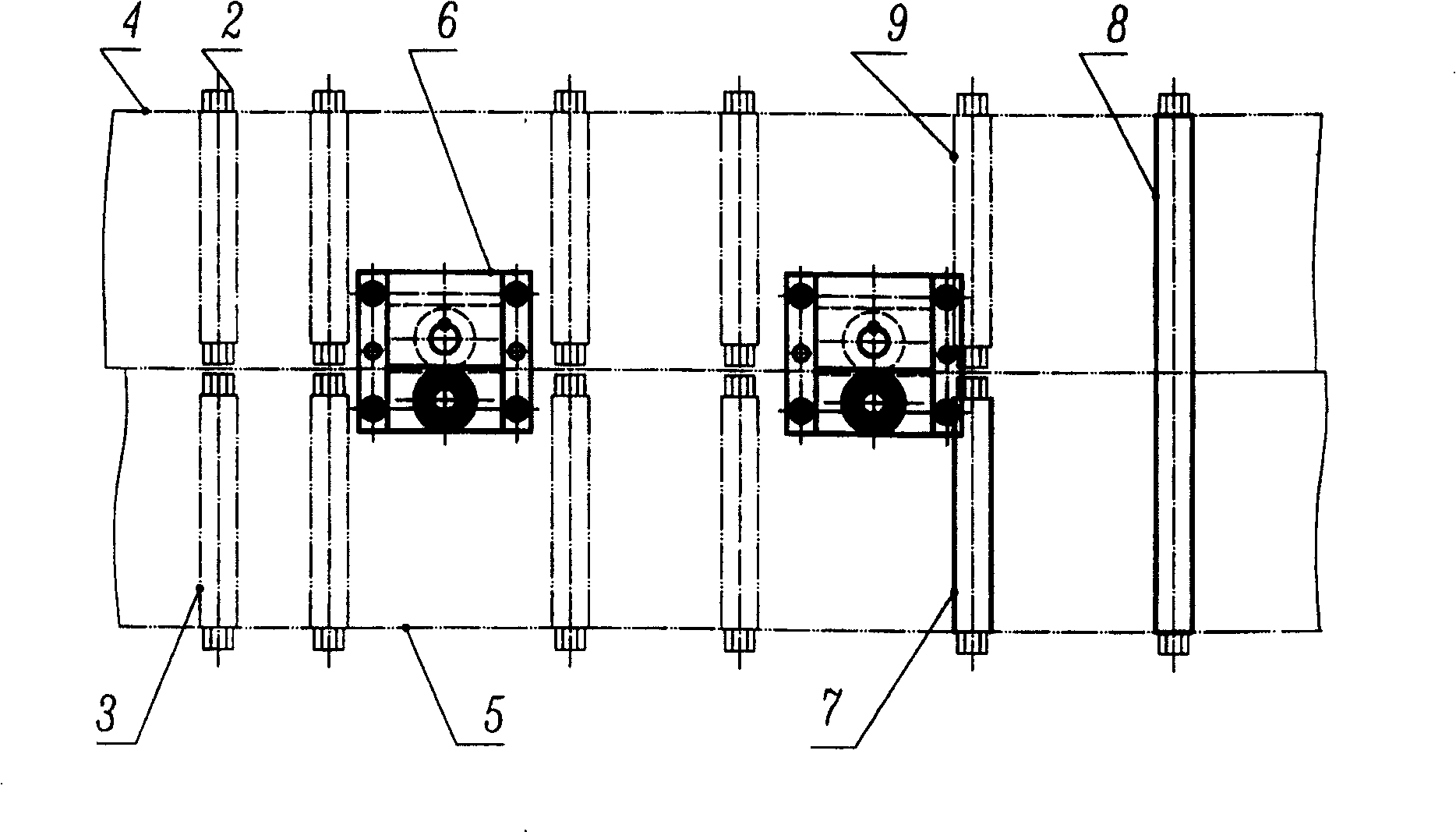

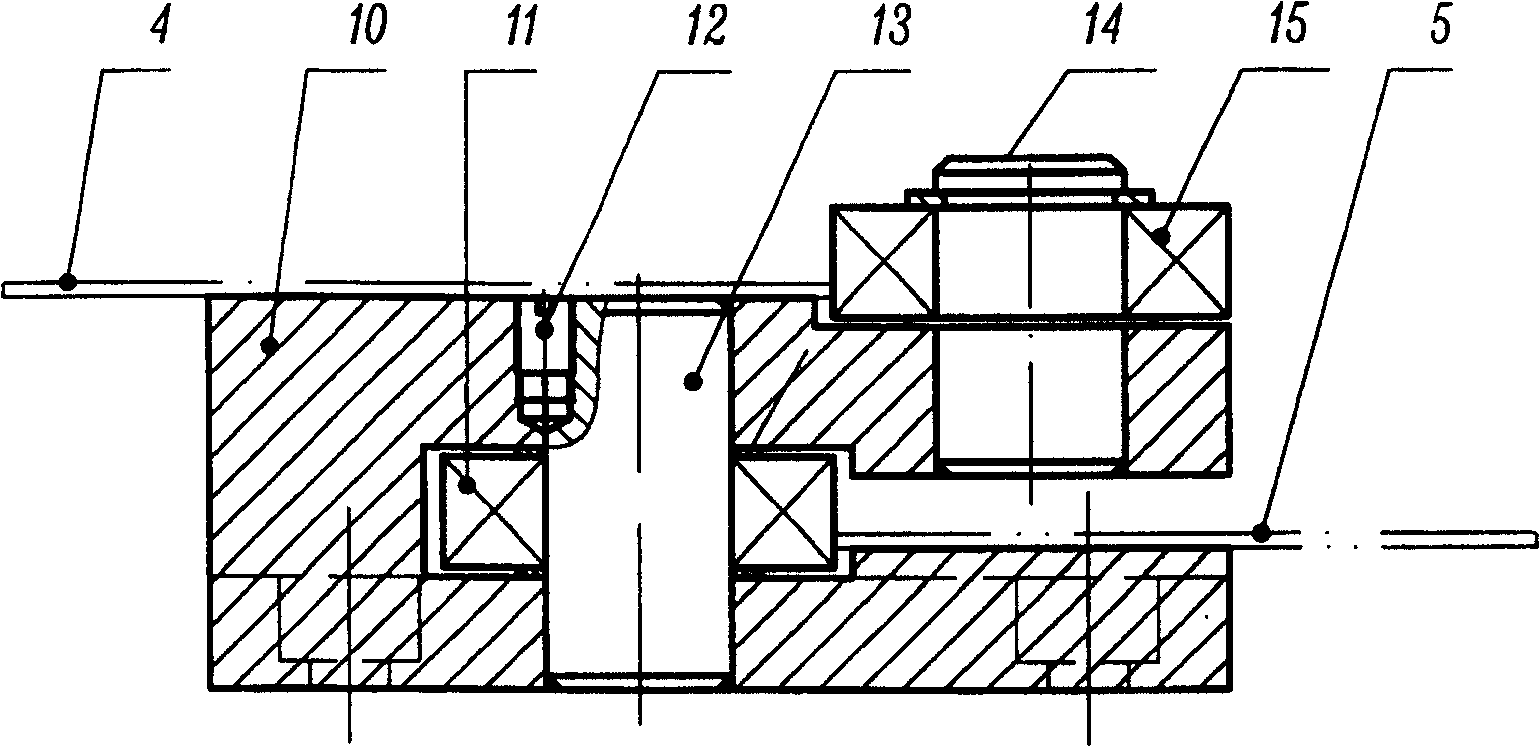

[0017] according to Figure 1-4 The specific structure of the utility model is described in detail. The device includes a frame 1, a plurality of upper supporting rollers 2 and a transition positioning roller 9 for the upper cold-rolled plate 4 on the assembly frame 1, a plurality of lower supporting rollers 3 for the lower cold-rolled plate 5 and a transition positioning Roller 7, the spacer roll 8 shared by cold-rolled plates 4, 5 and misalignment locator 6 etc. parts. Among them, the specifications, shapes, and quantities of frame 1, upper and lower supporting rollers 2, 3, transition positioning rollers 7, 9, and limit rollers 8 should be determined according to the specifications of the cold-rolled plates 4, 5 to be connected. The dislocation locator 6 should be used in pairs based on the principle that two points form a straight line, that is, at least one pair. In order to ensure that the dislocation positioning of the butt joint cold-rolled plates 4 and 5 is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com