Shear type gripper

A gripper and scissor unit technology, which is applied in the field of scissor mechanism, can solve the problems that the working platform of the elevator is not stable, easy to bend, and the processing accuracy is not high, so as to achieve convenient and fast clamping process and stable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

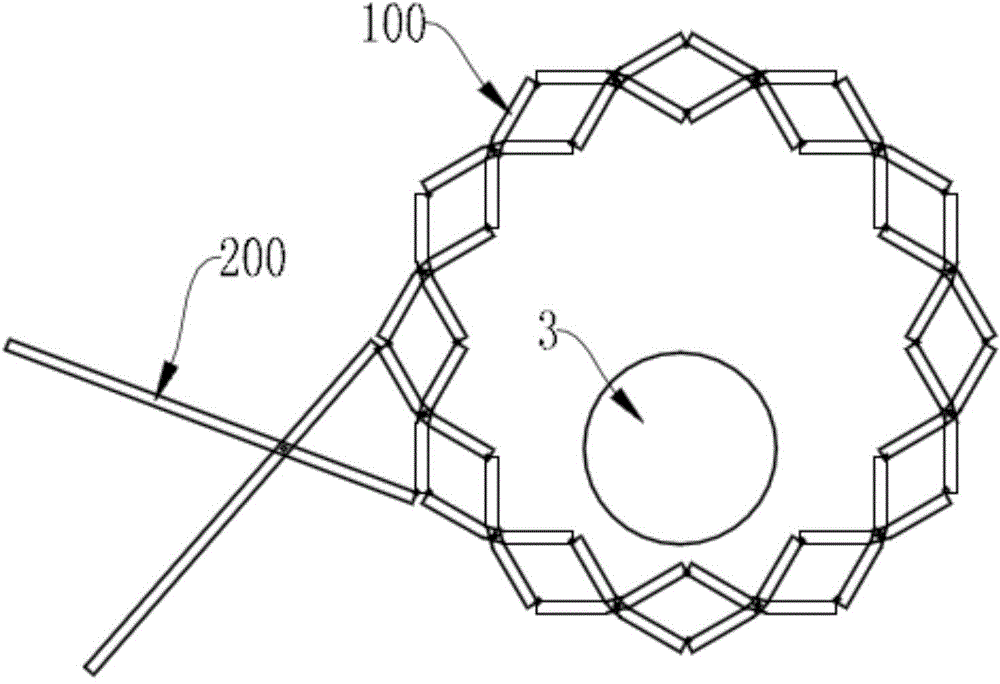

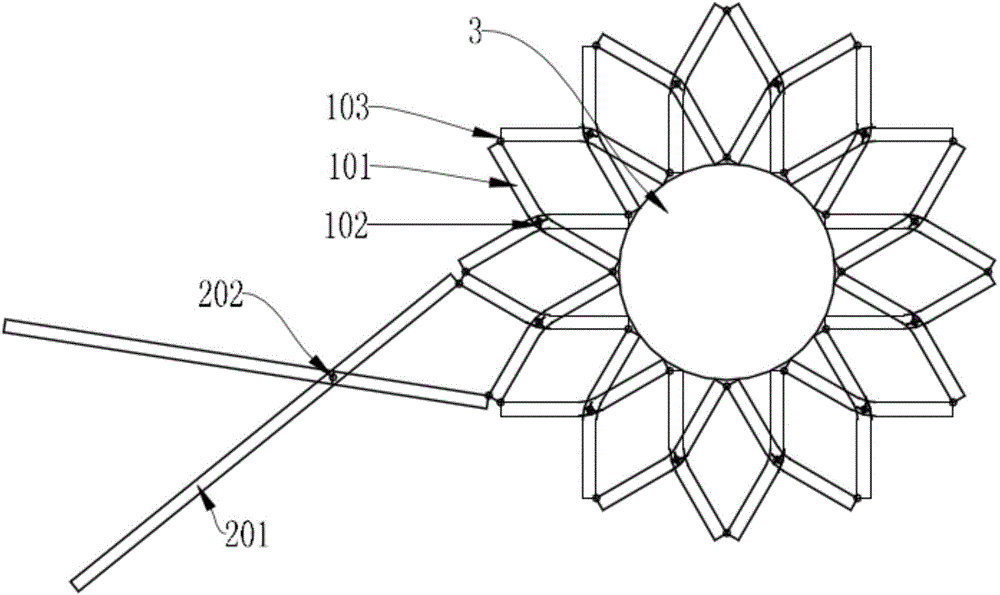

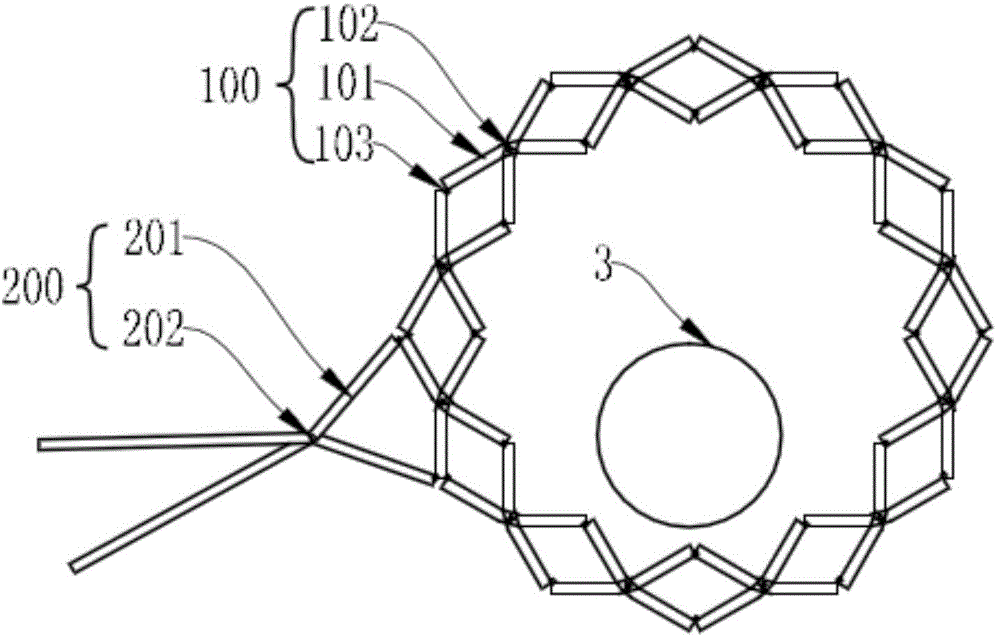

[0023] Such as figure 1 and figure 2 As shown, a scissor gripper; includes a synchronously telescopic clamping ring 100 and a drive assembly 200, and the drive assembly 200 drives the clamping ring 100 to realize synchronous telescopic expansion;

[0024] The clamping ring 100 is a ring structure formed by connecting several scissor units end to end through connecting shafts 103. The scissor units are an X-shaped structure composed of connecting rods 101 and scissor shafts 102. The middle part of the connecting rod 101 is hinged by the scissor shaft 102; the two ends of the connecting rod 101 are hinged with the connecting rod 101 at the corresponding position in the adjacent scissor unit through the connecting shaft 103;

[0025] The drive assembly 200 is an X-shaped structure composed of a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com