Rail vehicle frame air spring hole anti chip tooling

An air spring and rail vehicle technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the workload and difficulty of cleaning procedures, affecting processing efficiency, and iron filings entering, and preventing iron filings from entering additional The effect of air chamber, saving internal space and ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

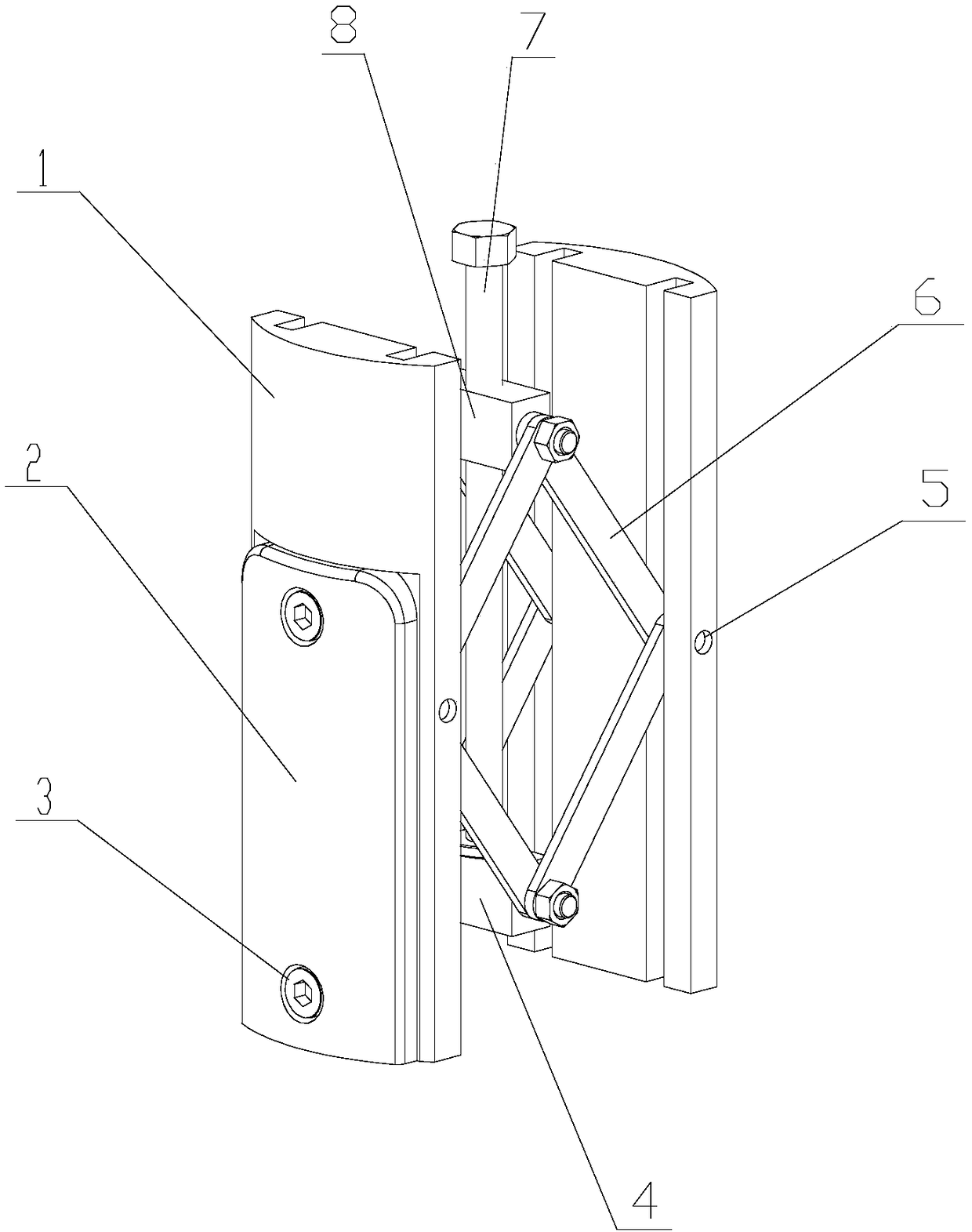

[0020] Such as figure 1 As shown, it is the rail vehicle frame air spring hole anti-chip tooling, which has symmetrically arranged baffles 1, the outer surface of the baffle 1 is a curved surface suitable for fitting the inner surface of the lower hole of the air spring, and the outer surface of the baffle 1 passes through the screw 2 A positioning block 3 suitable for embedding in the gap of the lower hole of the air spring is fixed. The shape and size of the positioning block 2 are adapted to the gap of the lower hole of the air spring. The inner side of the symmetrical baffle 1 is fixed together by a four-bar linkage mechanism 6, and the four-link When the mechanism is in the retracted state, the peripheral size of the tooling is smaller than the upper hole of the air spring, so that the tooling can be put in from the upper hole of the air spring; Together, the positioning block 2 is embedded in the gap in the lower hole of the air spring. Such as figure 1 As shown, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com