Pipe end part grinding device

A technology for pipe fittings and grinding parts, which is applied in the field of pipe fitting end grinding devices, which can solve problems such as error-prone, complicated control process, and complex gas pipeline layout, and achieve the effects of low cost, simple gas pipeline layout, and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

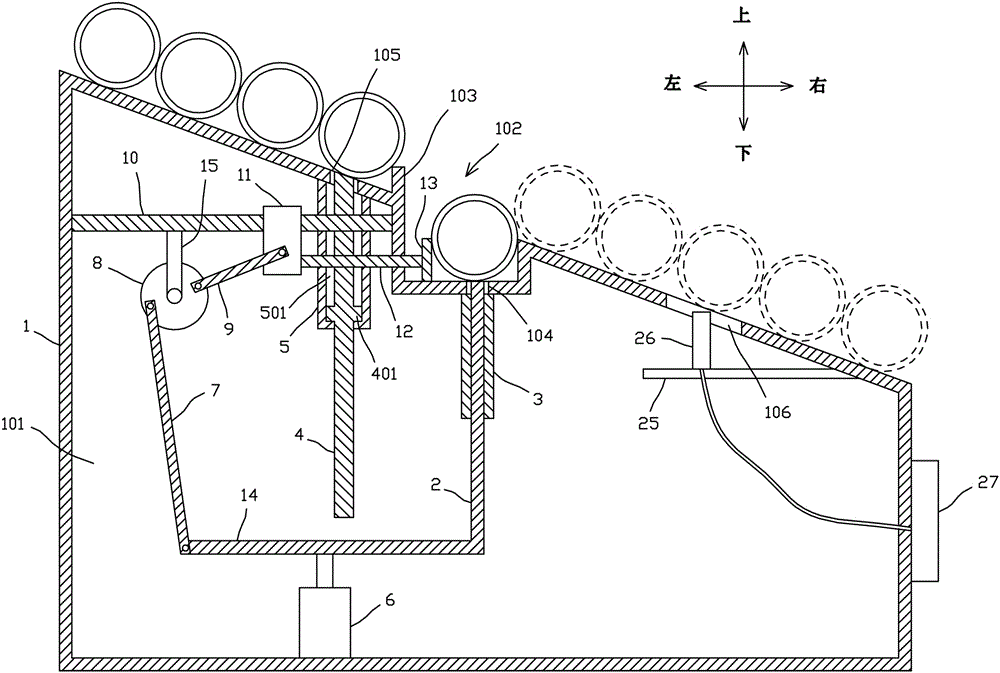

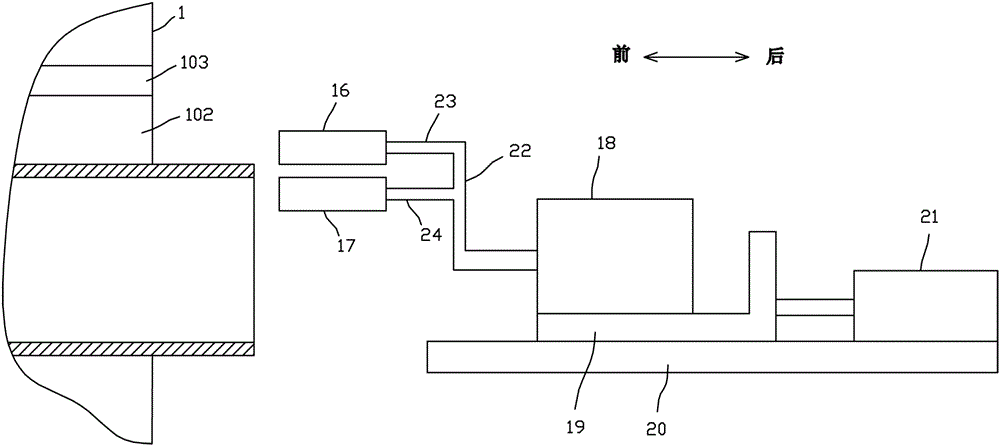

[0025] Depend on figure 1 , figure 2 As shown, the pipe fitting end grinding device of the present invention includes a frame 1, the upper surface of the frame 1 is inclined downward from left to right, the inside of the frame 1 is a cavity 101, and the upper surface of the frame 1 is provided with a front and rear The groove 102 extending in the direction, the width of the groove 102 is larger than the diameter of the pipe to be processed, the upper edge of the left side wall of the groove 102 is provided with a baffle part 103 extending vertically upwards, and a movable Platen 13.

[0026] The cavity 101 is provided with a first push rod 2, a first guide sleeve 3, a second push rod 4, a second guide sleeve 5, a first cylinder 6, a first connecting rod 7, a turntable 8, A second connecting rod 9 , a slide bar 10 , a slide block 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap