3D printer with multi-directionally movable nozzles

A 3D printer, multi-directional technology, applied in the field of 3D printing, can solve problems such as fatigue loss of connectors, printing accuracy errors, surface roughness, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

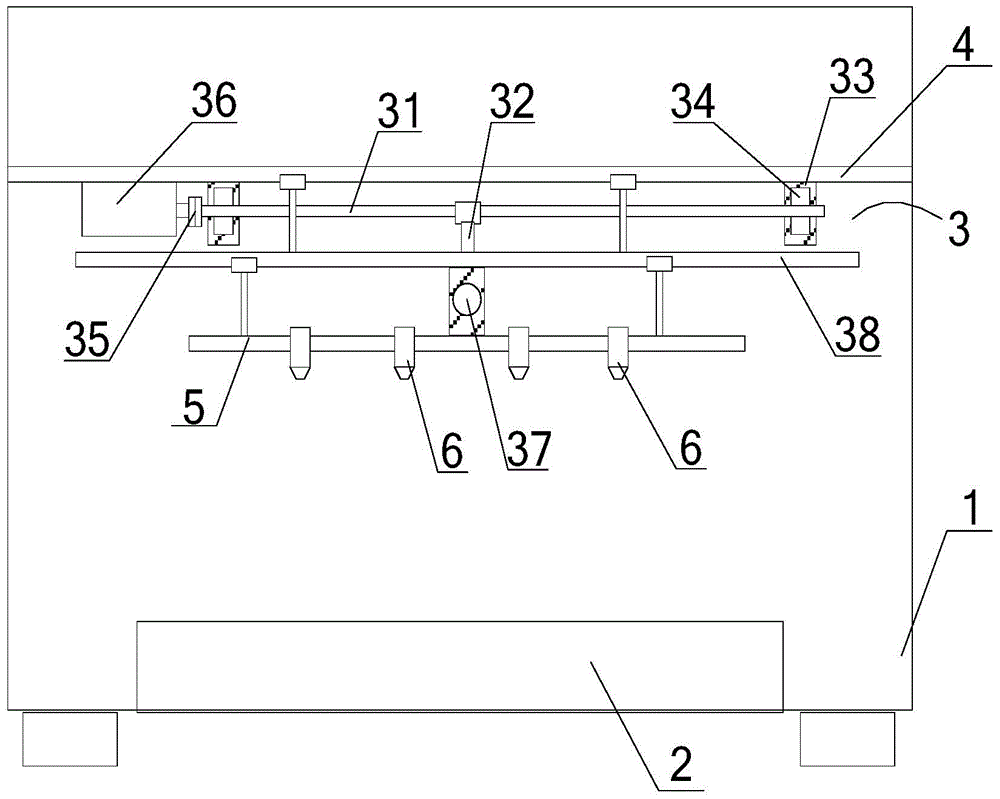

[0019] Such as figure 1 As shown, a 3D printer with a nozzle capable of moving in multiple directions, including a bracket 1 and a base 2 installed at the bottom of the bracket 1, an X / Y horizontal feed device 3, a first support platform 4, and a second support platform 5 , a raw material unit and a plurality of nozzles 6; the nozzles 6 are fixedly installed on the second support platform 5, and the second support platform 5 is installed on the lower side of the X / Y horizontal feeding device 3, and the X / Y direction is horizontally advanced The feeding device 3 is installed on the lower side of the first support platform 4, the first support platform 4 slides up and down along the guide rail on the inner wall of the bracket 1 through the slider, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com