Printing machine capable of changing operation mode

An operation mode and printing machine technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of inability to cover different lengths of printed matter, complex structure, single full-wheel mode or intermittent mode, etc., to achieve small changes and conversion Flexible, small-variation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the drawings and preferred embodiments.

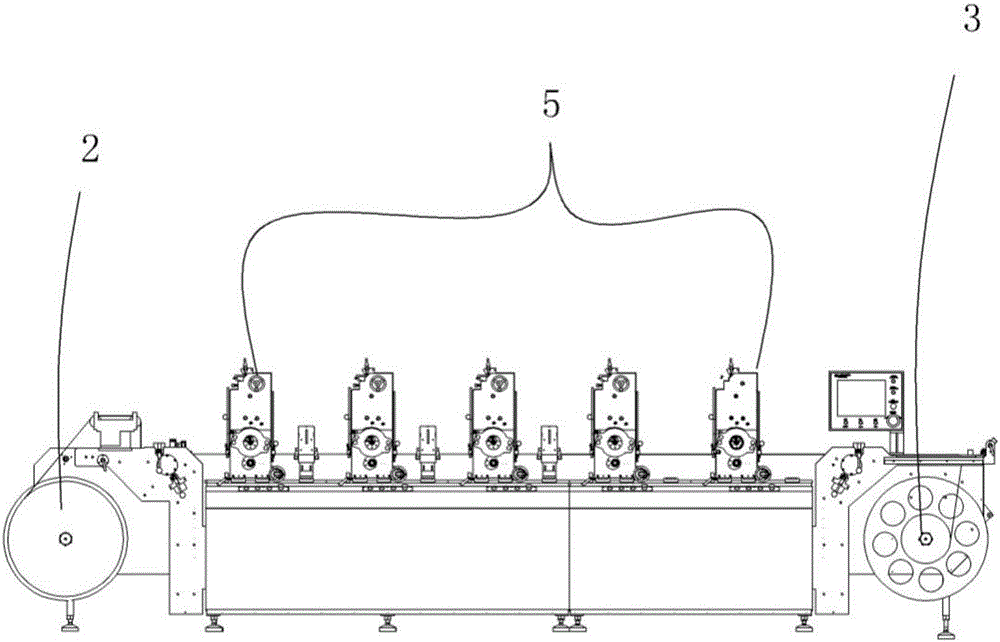

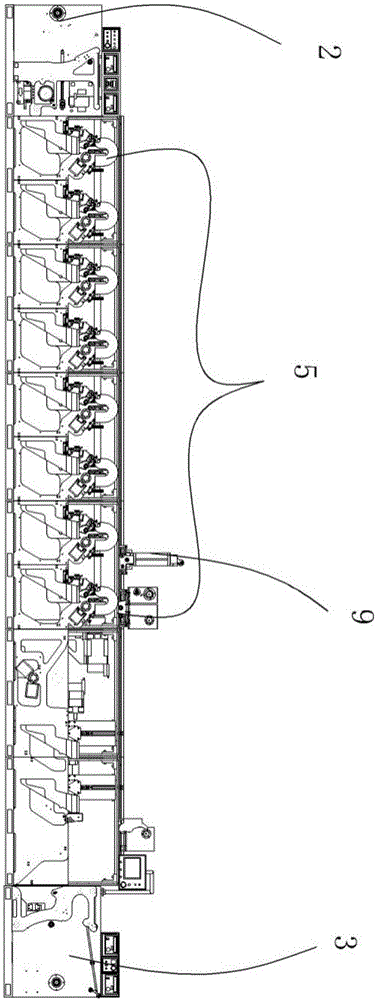

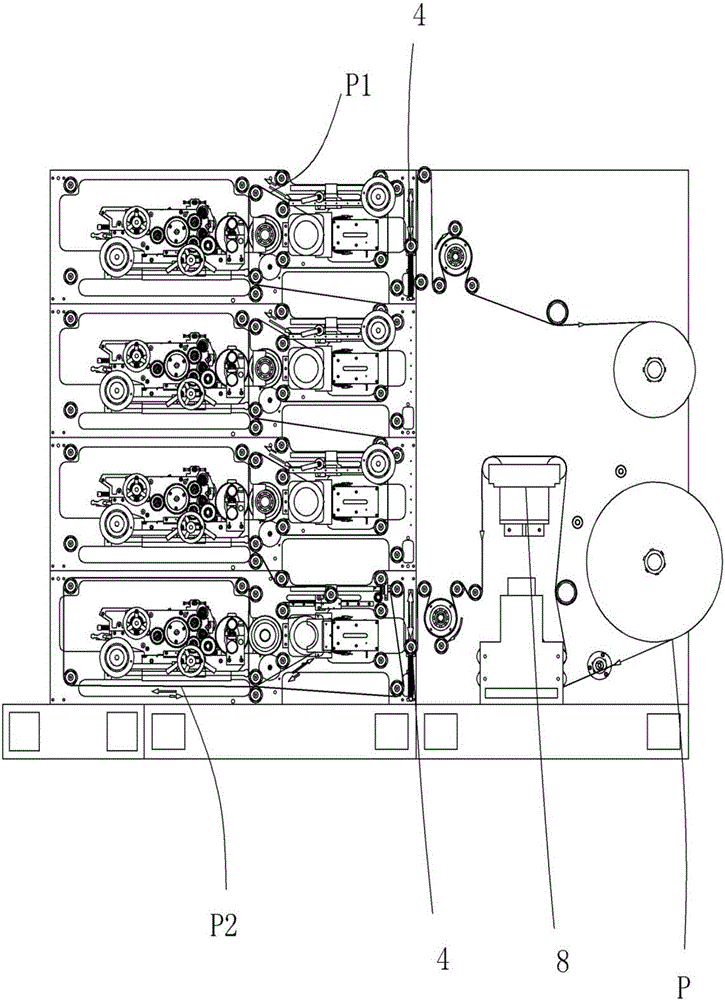

[0019] Such as Figure 1-Figure 5 As shown, a printing machine capable of changing operating modes according to the present invention includes a base 1, on which a feed shaft 2 and a discharge shaft 3 are arranged, and the feed shaft 2 is connected with a first servo traction roller 21, The unwinding shaft 3 is connected with a second servo traction roller 31, the first servo traction roller 21 and the second servo traction roller 31 are respectively provided with an intermittent storage swing assembly 4, and the base 1 is also provided with a number of printing modules 5, printing modules 5 Including the color base assembly 51, the mounting wheel assembly 52, the printing bottom wheel assembly 53, the printing bottom wheel transmission servo assembly 54, the cooling roller assembly 55, and several material guide wheels 6. The printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com