Viscosity detection method for ink-jet printer

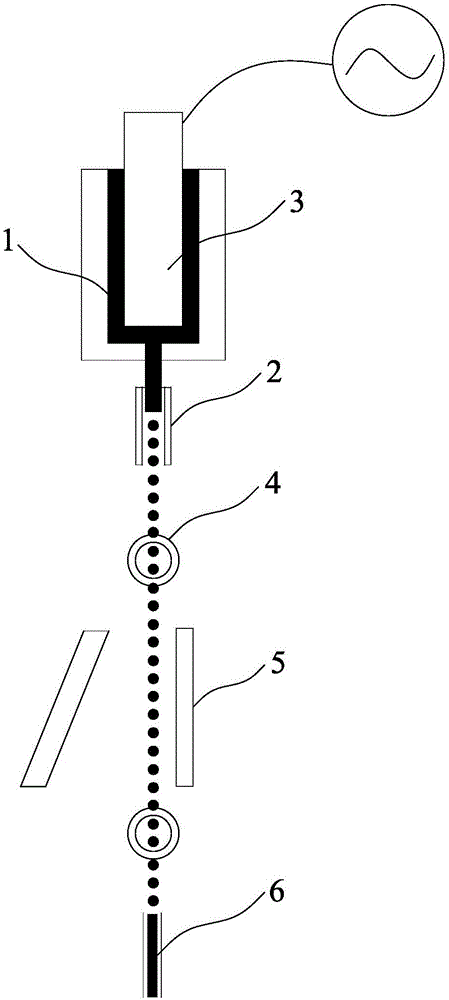

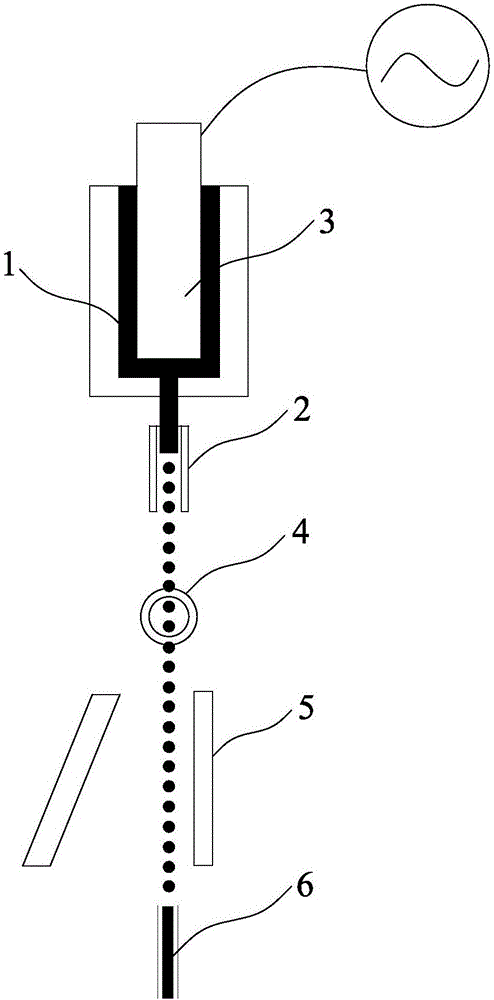

A detection method and inkjet printer technology are applied in the directions of measuring device, printing, flow characteristics, etc., which can solve the problems of complex structure, many nozzle components, high production and maintenance costs, and achieve the effect of ensuring printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

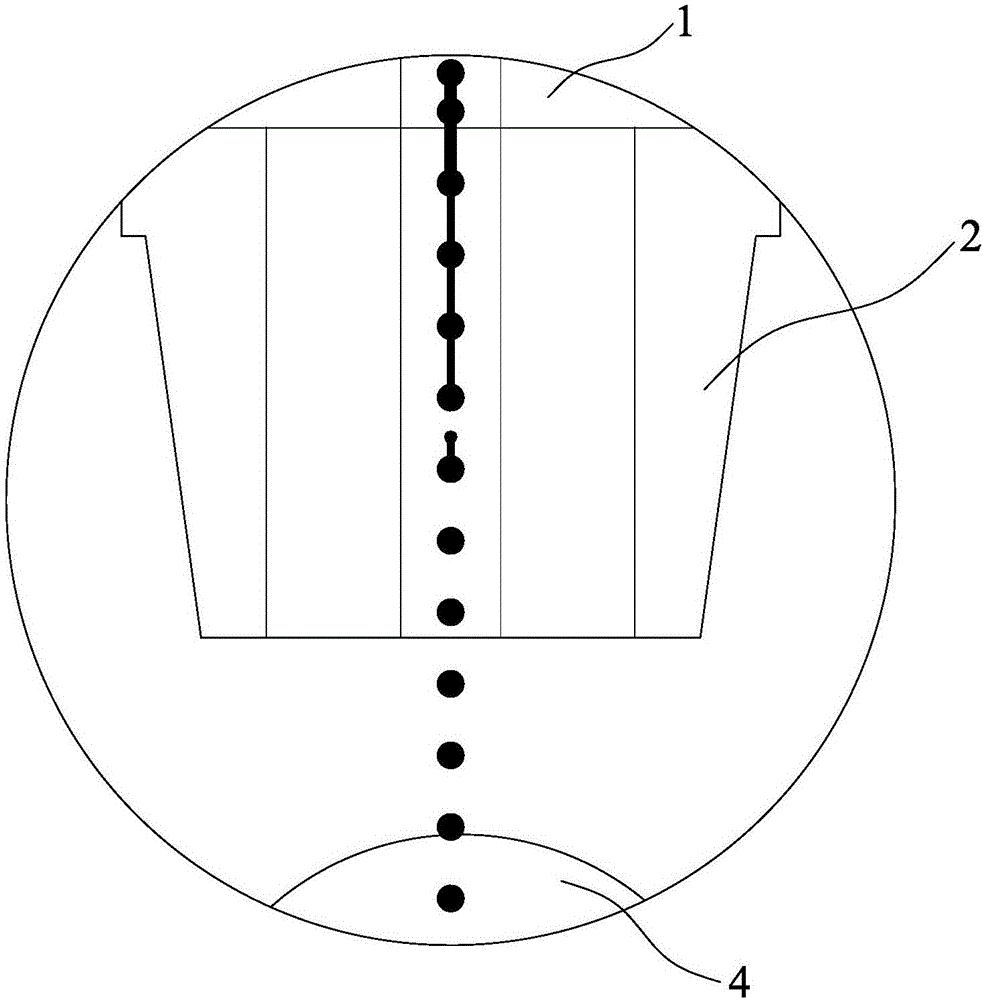

[0024] The inkjet printer viscosity detection method disclosed by the present invention, its steps are:

[0025] 1. Set an initial crystal oscillator frequency f, obtain the period T of ink dot formation according to the crystal oscillator frequency, divide the period T into N equal parts, and use is a time gradient;

[0026] 2. Within a period T, starting from the time starting point of a period, each increment The charging pole will charge several ink dots at a certain time, and record the time value t of each charging n1 , 1≤n≤N;

[0027] Third, at each time gradient Inside, the phase detector continuously detects a dot with a dot, if a dot with a dot is detected, a pulse signal is generated and sent to the main controller, and the time gradient is recorded The time value t when a pulse signal is detected within n2 , if at this time gradient If the internal main controller does not detect the pulse signal, the charging pulse time will be delayed time;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com