A front car body double beam channel structure

A channel structure and double-beam technology, which is applied to the upper structure, upper structure sub-assembly, vehicle components, etc., can solve the problems of reduced comfort, poor local stiffness and strength, local stress concentration, etc., to reduce the amount of collision deformation , Improve crash performance and increase stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

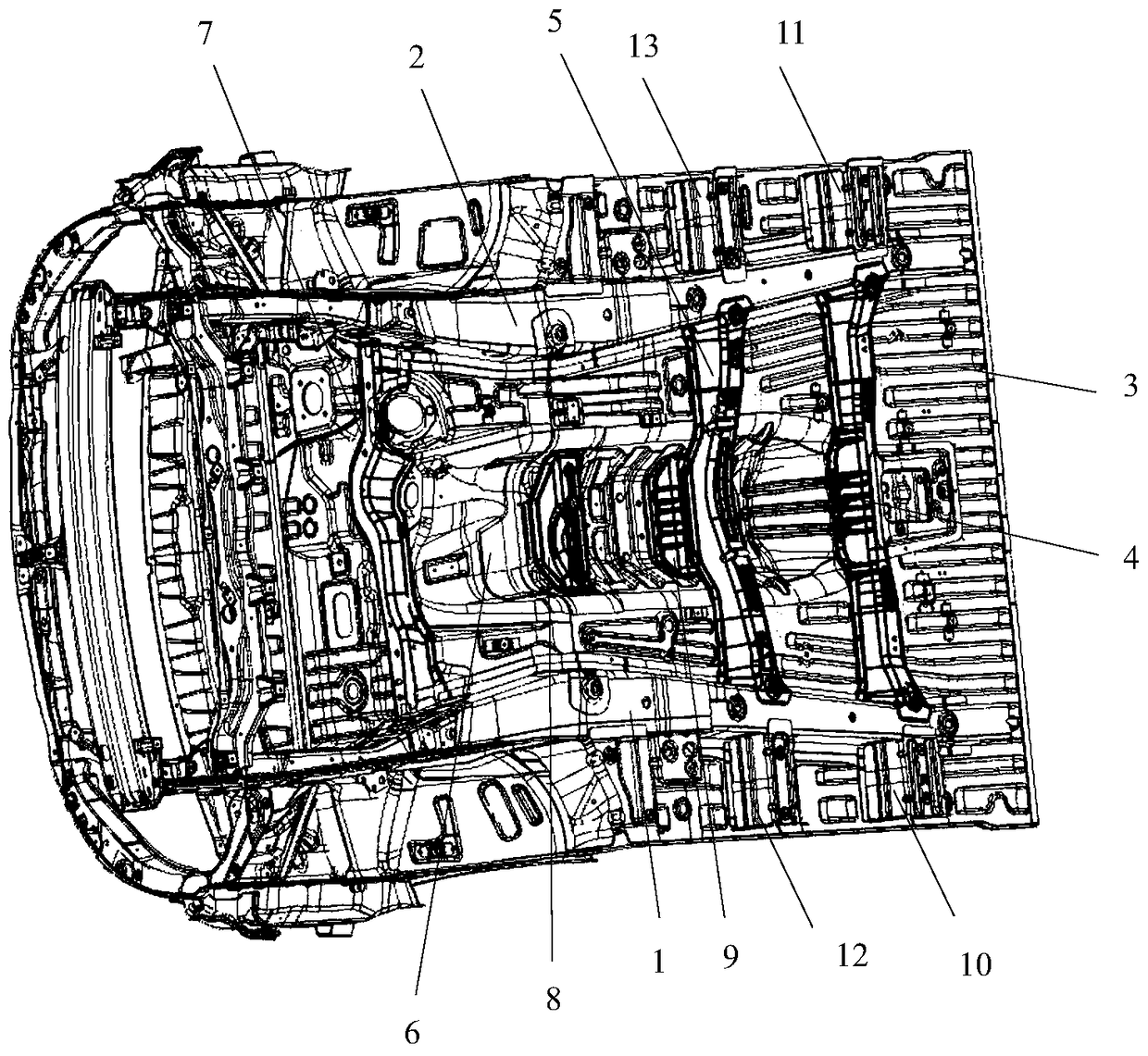

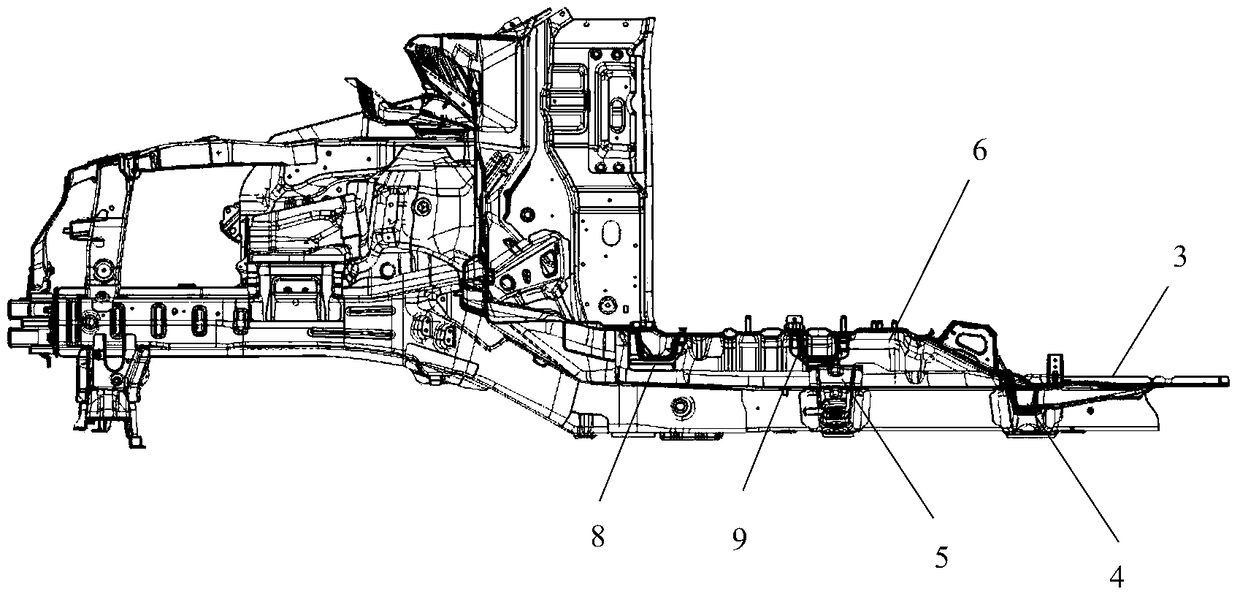

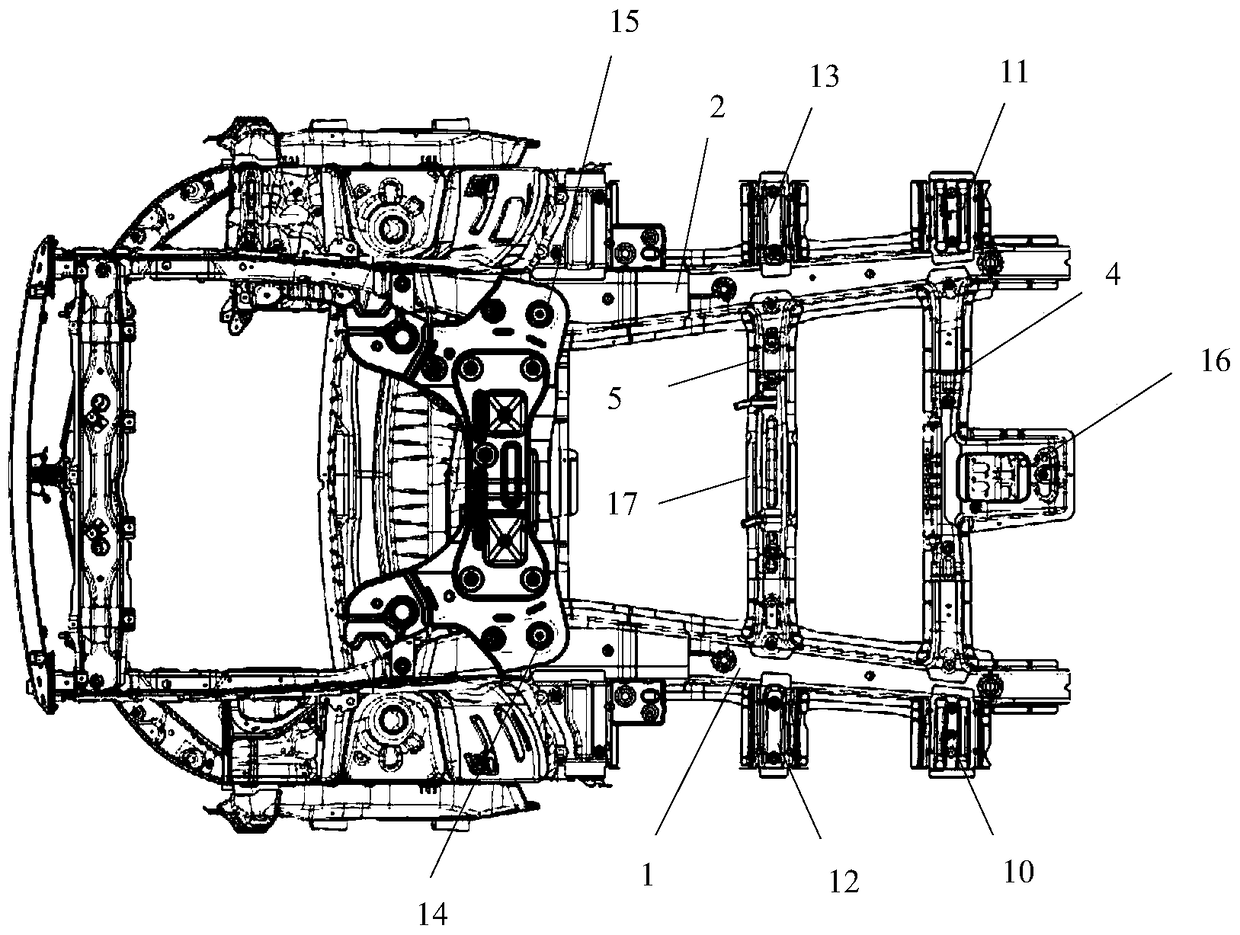

[0023] The following is a further description of a front vehicle body double beam channel structure of the present invention with reference to specific embodiments.

[0024] like Figure 1-4 As shown, a front vehicle body double cross beam channel structure includes a front longitudinal beam 1, a rear longitudinal beam 2, a front floor 3, a first beam 4 and a second beam 5, and the middle of the front floor 3 is provided with an upwardly protruding and The longitudinally extending central channel 6, the front part and the middle part of the central channel 6 are respectively provided with a first reinforcing plate 8 and a second reinforcing plate 9 transversely, and the first cross beam 4 and the second cross beam 5 are arranged at the place. Below the central channel 6, the two ends of the first cross beam 4 are respectively fixed vertically with the front longitudinal beam 1 and the rear longitudinal beam 2, and the two ends of the second cross beam 5 are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com