Spinel prepared from water plant sludge and preparation method thereof

A technology of spinel and dewatered sludge, which is applied in the field of sludge treatment, can solve the problems of high price and less iron-aluminum spinel, and achieve the effects of convenient operation, long service life and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present invention aims to provide a method for preparing iron-aluminum spinel or magnesia-aluminum spinel using water plant sludge:

[0029] Process flow: dehydration and crushing, mixing of ingredients, forming and calcination.

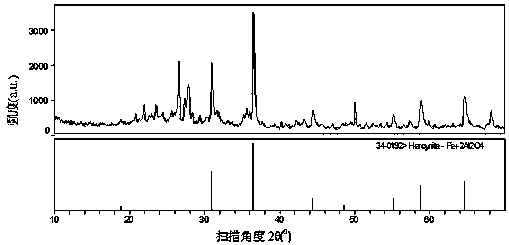

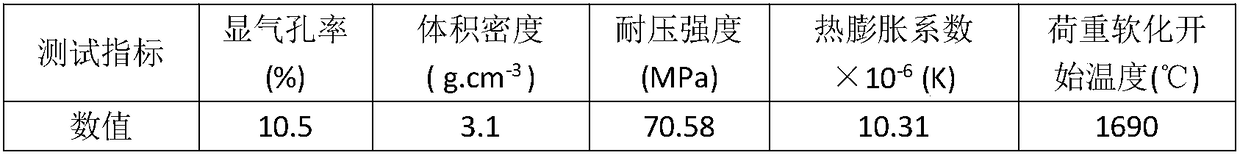

[0030] The invention determines the requirements of water plant sludge ingredients, the optimal temperature and time for high-temperature roasting, and determines the phase composition of the new material.

[0031] (1) Preparation of sludge samples from water plants

[0032] The water plant sludge is taken from a large water treatment plant in Beijing. The treatment process of the water plant adopts the coagulation sedimentation sand filter and the activated carbon filter treatment process. The sedimentation tank muddy water, the sand filter and the activated carbon filter backwash water are filtered by pressure The press filter is reused, and the mud cake is the sludge of the water plant. Retrieve the dewatered sludge from the water treatment pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com