A device for uniformly adding powdery materials, an installation method and a use method

A technology of adding devices and powdery materials, which is applied in the direction of furnaces, furnace types, blast furnace parts, etc., to achieve the effect of solving secondary pollution, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

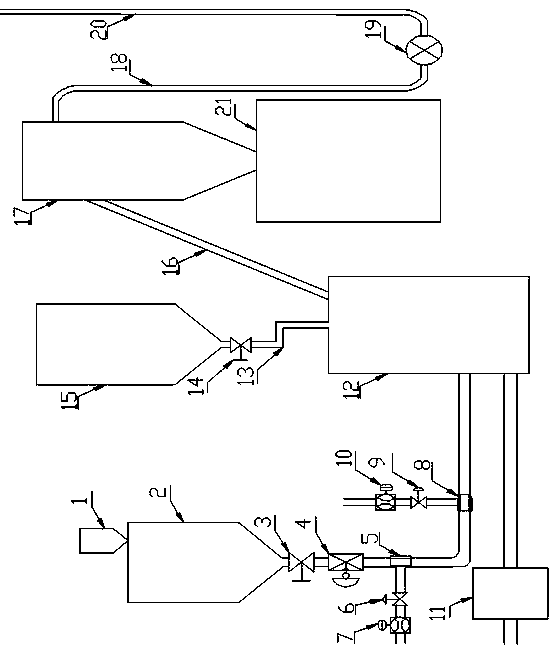

[0015] see figure 1 , a device for evenly adding powdery materials, the adding device includes a powder bin 2, a bin top dust collector 1, a coal mill 12, a raw coal bin 15, a bag filter 17, a coal dust bin, 21 main exhaust fans, the bin The top dust collector is arranged on the top of the powder bin, and the powder bin 2 and the coal mill 12 are connected through a pipeline, and the pipeline is provided with a shut-off valve 3, an adjustable star-shaped ash discharge valve 4, and a fluidizer 5; The pipeline between the raw coal bunker 15 and the coal mill 12 is provided with a coal feeder 13 and a shut-off valve 14. The coal mill 12 is connected to the bag filter 17 through the coal mill outlet pipeline 16. The dust collector 17 is arranged above the pulverized coal bin 21, and the bag dust collector is connected to the main exhaust fan 19 through the outlet pipe of the dust collector, and the other end of the main exhaust fan is connected to the chimney 20. In this plan, th...

Embodiment 2

[0017] see figure 1 , as an improvement of the present invention, the adding device also includes a secondary gas supply device, and the secondary gas supply device includes a gas supply pipeline, a secondary gas supply device 8, a second gas regulating valve 9, a gas flow meter 10. The secondary gas supply device 8, the second gas regulating valve 9, and the gas flow meter 10 are all arranged on the gas supply pipeline. Install a secondary air supply device on the air supply pipeline, and under the boost of the gas ejected from the secondary air supply device and the main exhaust fan of the pulverizing system, CDQ powder can be continuously fed into the middle of the coal mill to avoid blockage of the conveying pipeline , and the mixed coal powder produced by the coal mill is evenly mixed, and is collected by the bag filter into the coal powder bin. This control technology can make up for the defects of the existing technology. The rest of the structures and advantages are e...

Embodiment 3

[0019] see figure 1 , as an improvement of the present invention, the adding device further includes a hot flue gas system, which is connected to the coal pulverizer through a pipeline, and is used for drying the coal powder in the coal pulverizer. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com