Prebaked anode aluminum electrolytic cell anode configuration method

A technology of an aluminum electrolytic cell and a configuration method, which is applied in the field of anode configuration of an intermediate point blanking pre-baked anode aluminum electrolytic cell, can solve the problems of anode effect, unfavorable alumina melting, hindering the flow of electrolyte, etc., and achieves the improvement of current efficiency, The effect of reducing the seam area and expanding the anode area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

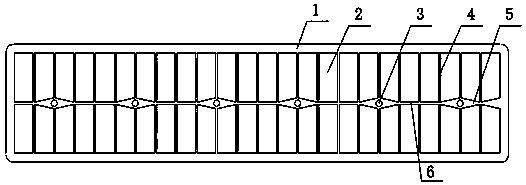

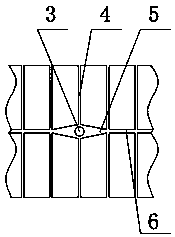

[0017] like figure 1 A prebaked anode aluminum electrolytic cell anode configuration method is shown, including an electrolytic cell 1, 48 anode carbon blocks 2, and a feeding point 3, and the central slits along the long axis of the electrolytic cell are arranged alternately with narrow central slits 6 and diamond-shaped central slits 5 ; The bottom and front and back of the feeding point 3 are diamond-shaped middle seams 5, and the length of the diamond-shaped middle seams 5 is two anode carbon blocks plus the total width of two gaps 4, and the diamond-shaped middle seams are composed of four anode carbon blocks 2 and adjacent gaps. 4 surrounded.

[0018] The ends of the short sides of the four anode carbon blocks 2 facing the wide middle slit are all cut off, so that the section of the anode carbon block 2 is trapezoidal; the width of the diamond-shaped middle slit surrounded by the four trapezoidal anode carbon blocks 2 is between 100-300mm, the narrowest The width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com