Airflow balance device suitable for blowing-carding cotton road transportation

A balancing device and blowing-carding technology, applied in textiles and papermaking, fiber processing, fiber feeding, etc., can solve problems such as pipeline blockage, large pressure difference of mesh plate, severe air separation, etc., to achieve flexible installation and compact structure , easy to use and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

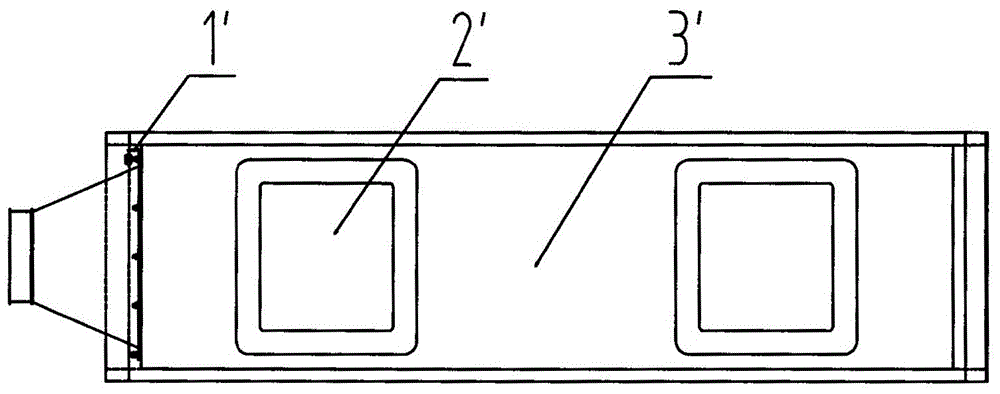

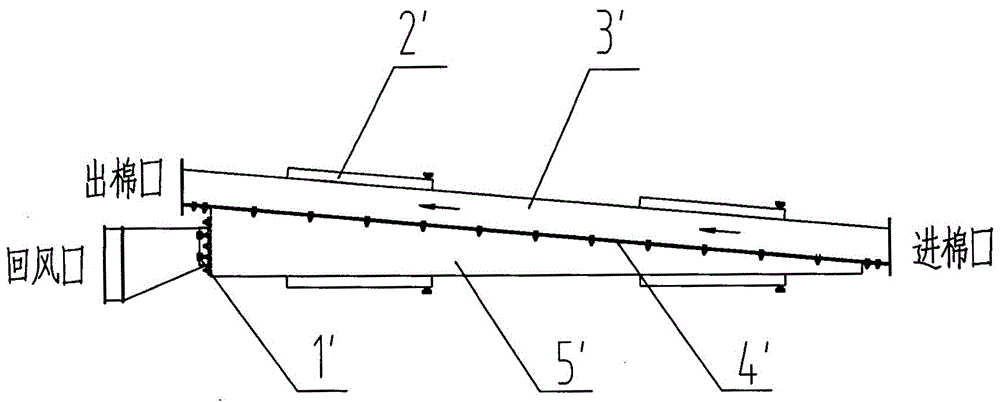

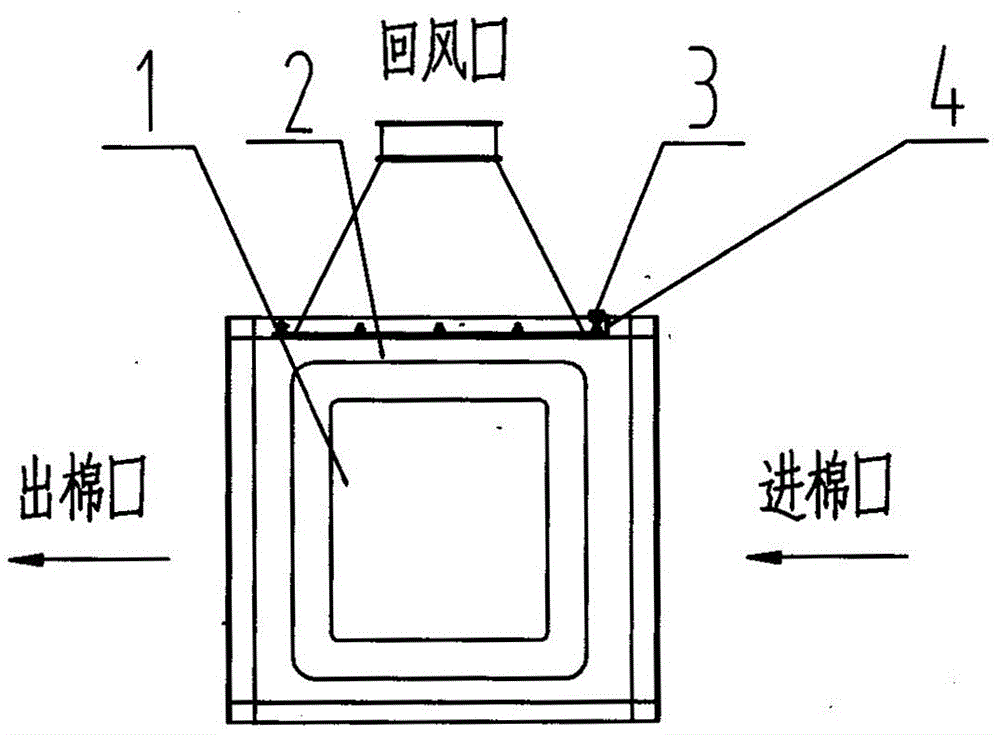

[0034] like image 3 , Figure 4 , Figure 5 As shown, the air flow balance device suitable for blowing and carding combined cotton road transportation of the present invention includes a cotton delivery channel 2 with a cotton outlet at the left end and a cotton inlet at the right end, and a cotton channel observation window 1 at the front side of the cotton delivery channel. , the return air diffuser box 5 located at the rear side of the cotton transport channel and connected to the cotton transport channel, the return air box adjustment plate 4 arranged on the top of the return air diffuser box, and the fastening knob 3 for locking the return air box adjustment plate and the air return pipe, and the airflow separation combination 6 arranged between the return air diffuser box 5 and the cotton transport channel 2; Between the filter screen 8 common composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com