Pure part plate combined industrialized house assembling structure which can be rapidly erected

A technology for assembling structures and components, applied in building components, building structures, buildings, etc., can solve the problems of low technical value in the industrial chain, inconvenient production and transportation, and no size modulus, and achieve a smooth appearance and no holes. , Light weight, smooth shape without holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, invention is described in further detail.

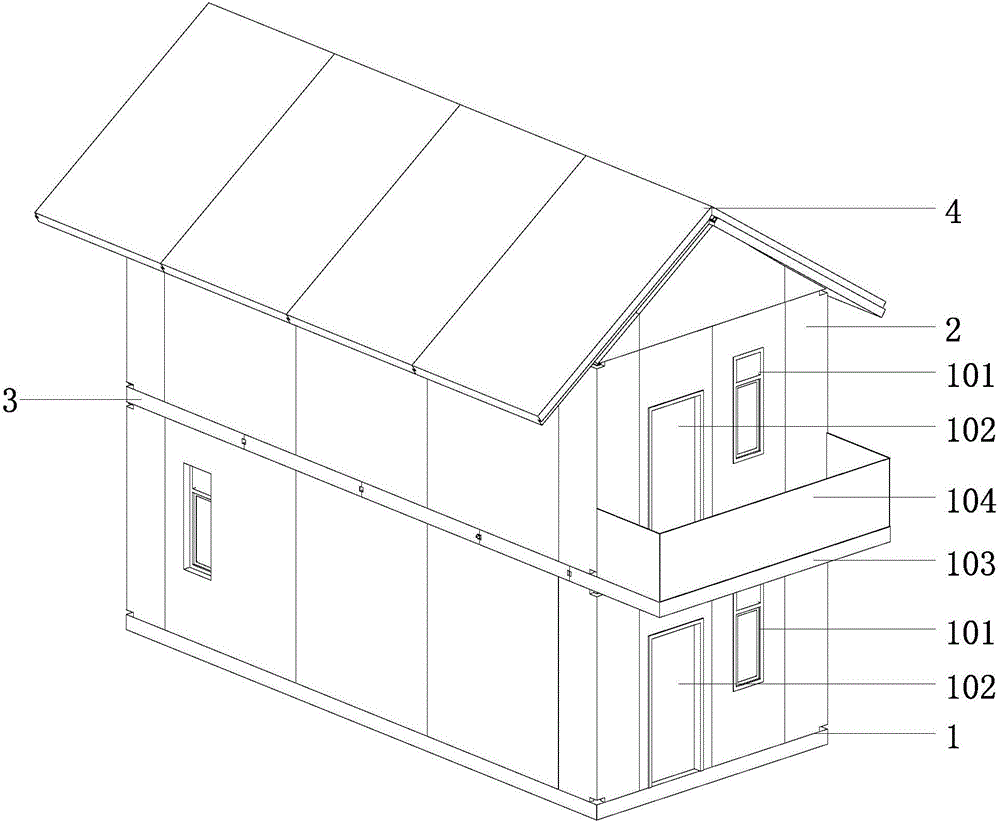

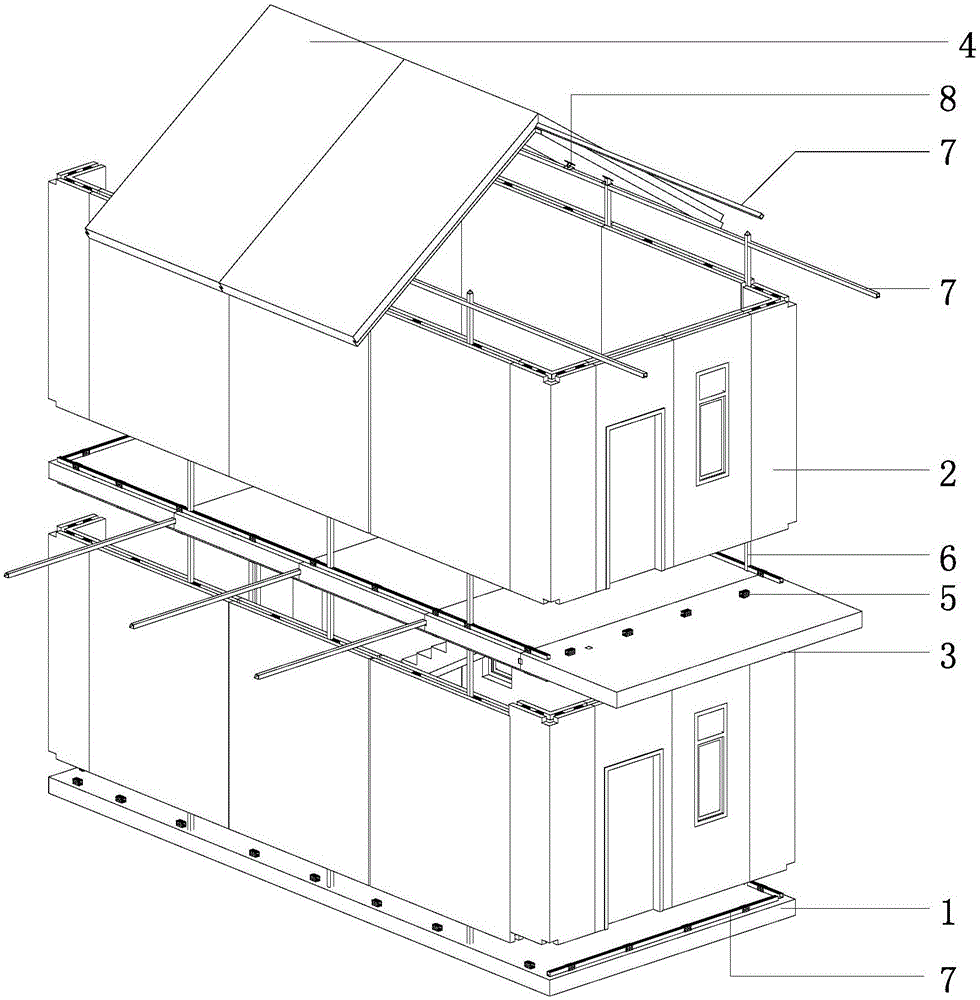

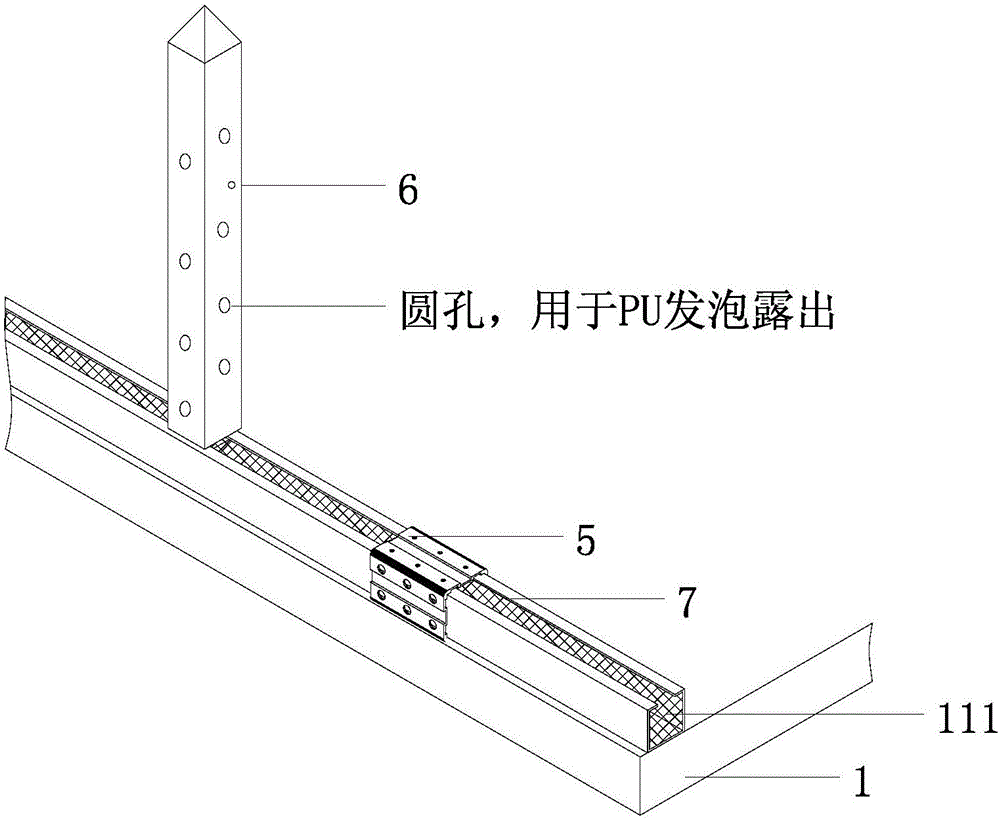

[0025] Such as Figure 1-10As shown, a fast-buildable assembly structure of pure component plate combination industrialized houses includes a base layer 1, a first layer of wall panels on the base layer 1, and a floor slab on the first layer of wall panels. Layer 3 and the second layer of wall panel body provided on the floor slab layer 3, and the roof panel 4 provided on the second layer of wall panel body. The above-mentioned base layer 1, the first layer of wall panels, the second layer of wall panels and the roof panel 4 all include a plurality of digital panels 2 spliced into a frame shape, and C through pipes connected to the upper and lower sides of the digital panels 2 respectively. Parts, the square tube connectors that are respectively provided on the left and right sides of the digital template 2, and the embedded parts 5 that are respectively provided with the C tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com