Hidden type outer door handle structure with lock-up function

A hidden door handle technology, applied in the field of auto parts, can solve problems such as difficult to open the door and complex structure of the hidden handle, and achieve the effect of high reliability, simple structure and small return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

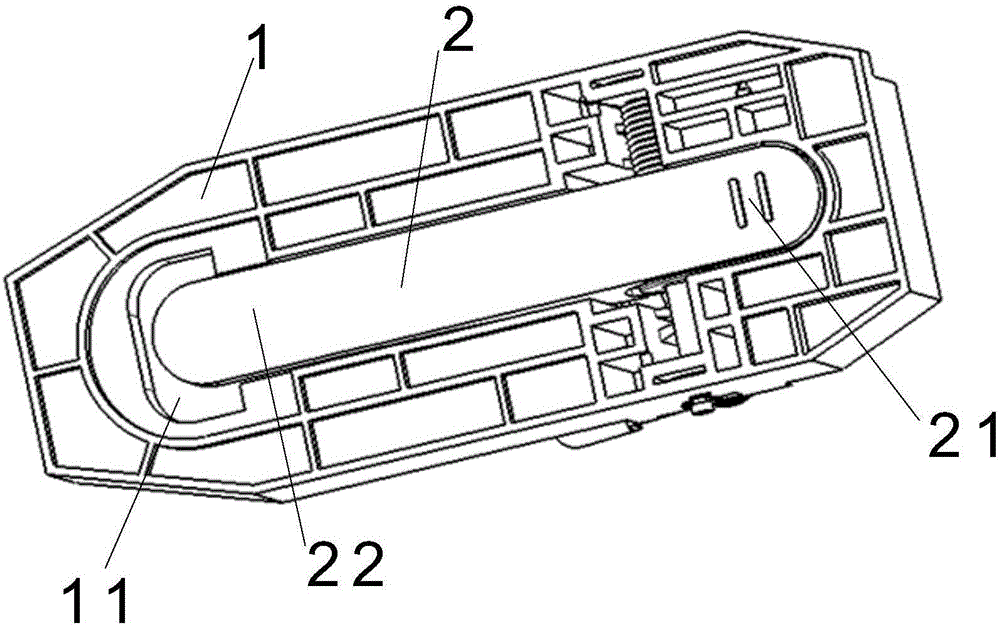

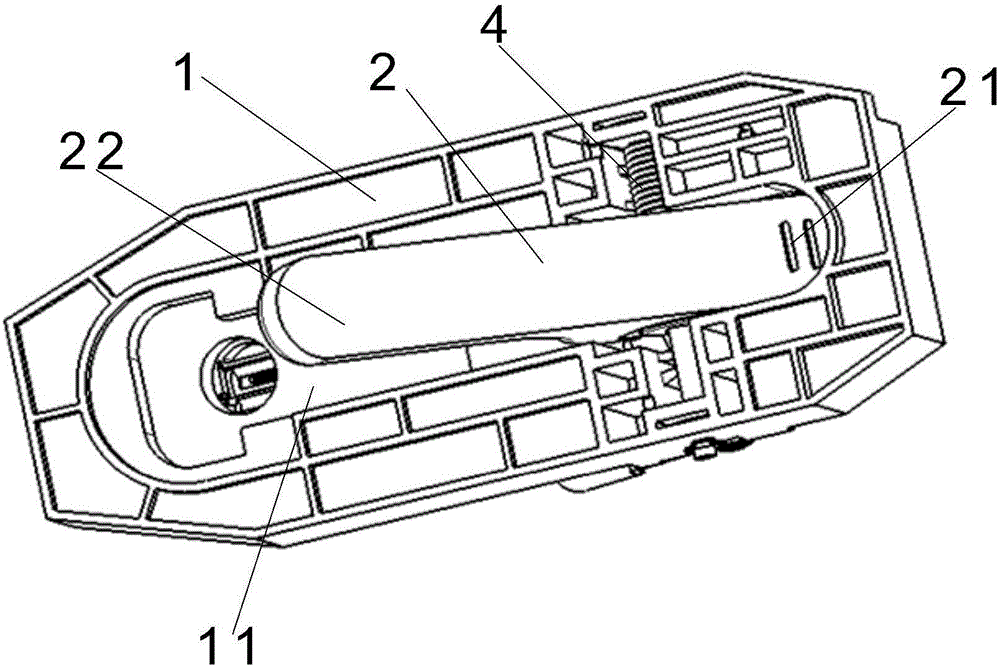

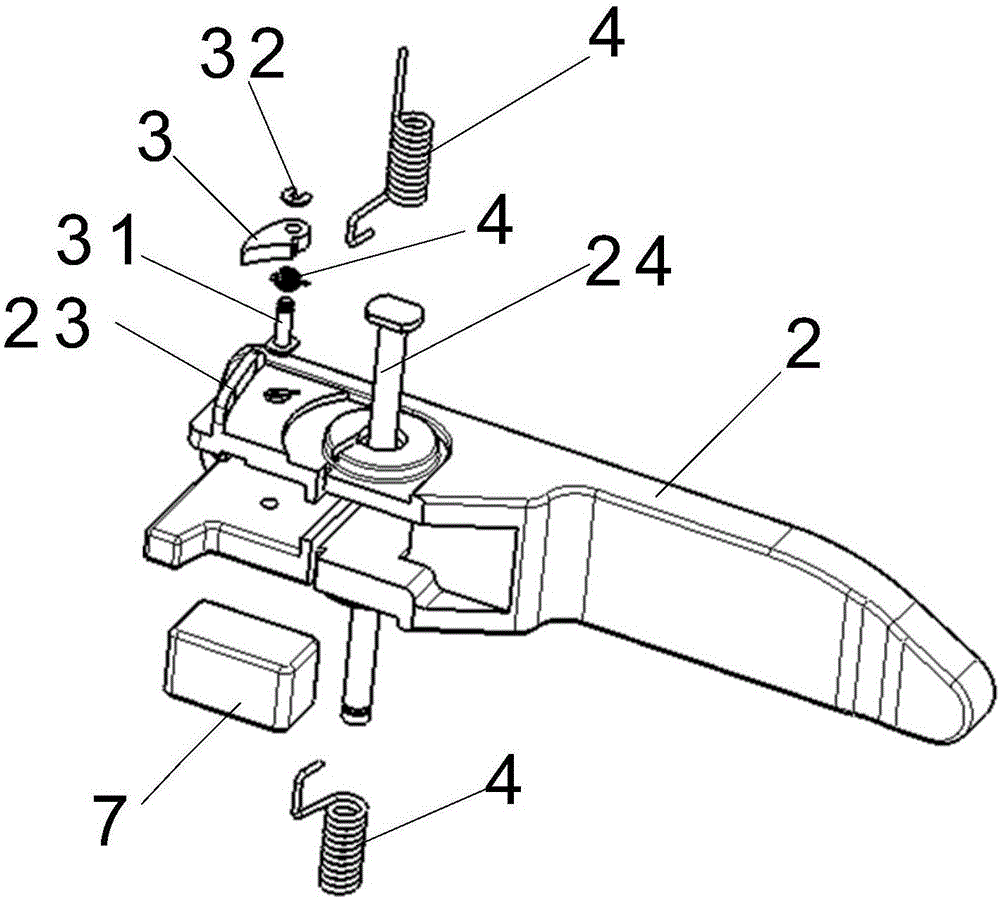

[0024] Such as figure 1 with 2 As shown, a hidden outer door handle structure with a locking function includes a base 1 and a handle 2; the base 1 is provided with an accommodating groove 11 for accommodating the handle 2, and the handle 2 A counterweight 7 is arranged inside, the middle part of the handle 2 is hinged with the base 1, and the handles 2 on both sides of the hinge are respectively the pressing end 21 and the pulling end 22, specifically, the handle 2 passes through the handle The pin shaft 24 is hinged with the base 1, and the return spring 4 between the handle 2 and the base 1 is sleeved on the handle pin shaft 24; the side of the pressing end 21 is provided with a lock block 3, a return spring 4 is provided between the locking block 3 and the side of the handle 2 and at the hinge joint between the handle 2 and the base 1, specifically, as image 3 As shown, the locking block 3 is rotated on the handle 2 through the locking pin 31, and the return spring 4 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com