Cable-stayed prestressed steel and concrete combined type fan tower

A fan tower, prestressed steel technology, applied in the installation/support of wind turbine configuration, wind power generation, engine components, etc., can solve the problems of poor anti-fatigue load action performance, poor crack resistance, etc., to improve crack resistance. and anti-fatigue performance, simple size, convenient tensioning and anchoring, and the effect of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

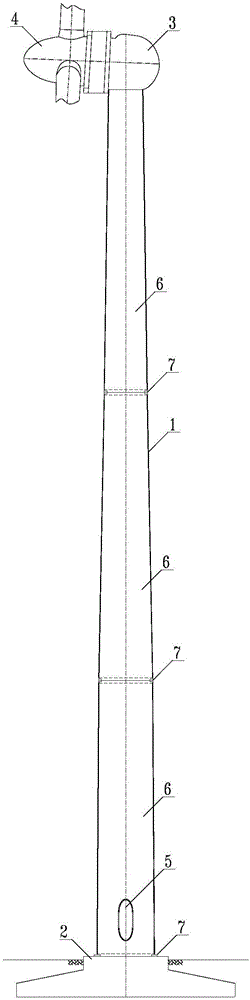

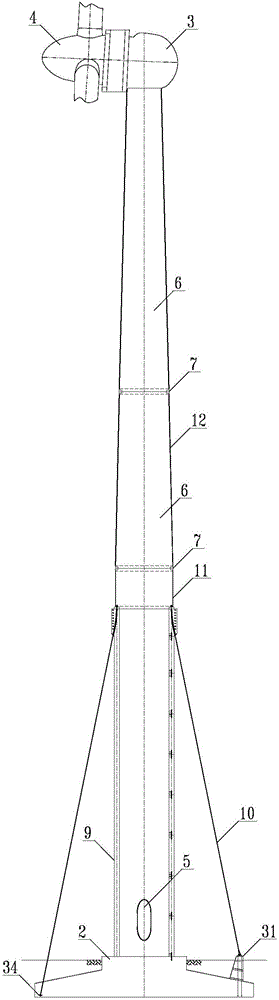

[0033] Example 1, Figure 2-Figure 10 As shown, the cable-stayed prestressed steel and concrete combined fan tower proposed by the present invention, the combined fan tower consists of a lower reinforced concrete tube structure 9, cable-stayed prestressed cables 10, a transition section 11, and an upper single-tube steel The barrel structure 12 is composed.

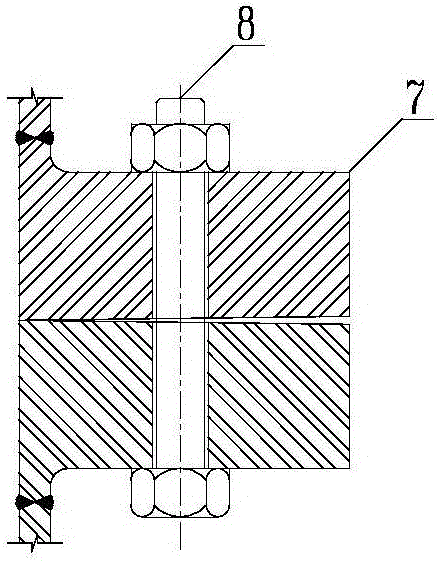

[0034] The upper single-tube steel cylinder structure 12 is connected to the transition section 11 through the forged transverse flange 7 at the bottom, the wind generator 3 and the wind wheel 4 are installed on the top, and the upper single-tube steel cylinder structure 12 is composed of a plurality of welded cylinder sections 6 connected. Forged transverse flanges 7 and flange bolts 8 are used to connect each welded cylinder section 6 .

[0035] The lower reinforced concrete cylinder structure 9 is composed of a bottom straight cylinder section 13 and a top transition section 14. The bottom straight cylinder section 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com