Lubrication type harmonic drive

A harmonic reducer and coupling technology, applied in the direction of gear lubrication/cooling, mechanical equipment, transmission parts, etc., can solve the problems of unsatisfactory solid lubricant lubrication effect, damage to the structure of the flexible outer gear cup, etc. The effect of prolonging life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

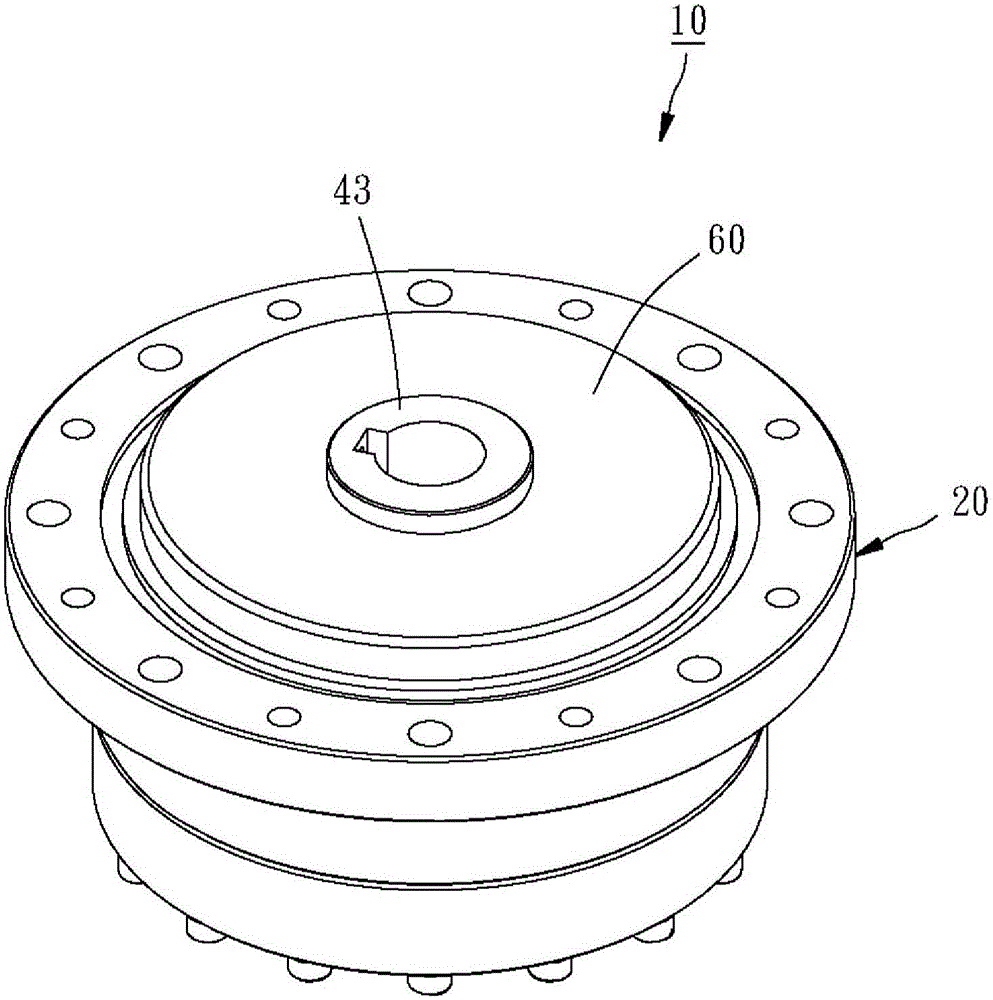

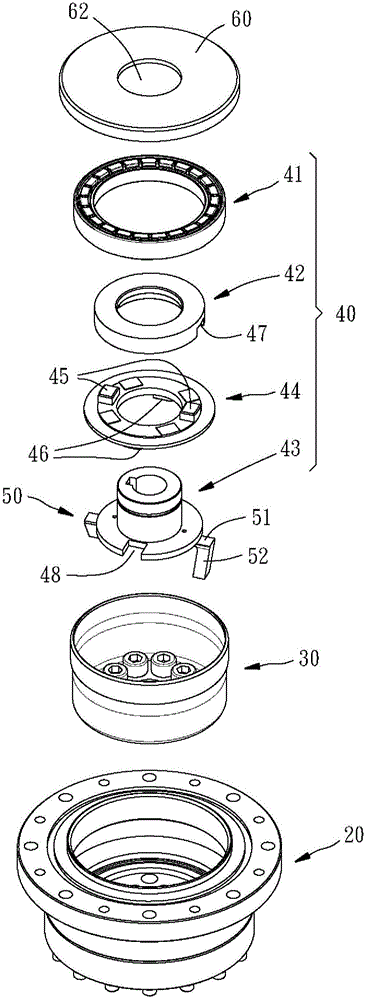

[0031] Please see first figure 1 and figure 2 , the lubricated harmonic reducer 10 of the first embodiment of the present invention includes a rigid inner gear ring 20, a flexible outer tooth cup 30, a wave generator 40, and two spoilers 50, wherein the spoiler 50 As long as there is at least one, and two are the best implementation.

[0032] The flexible outer gear cup 30 is disposed inside the rigid inner gear ring 20 and engages with the rigid inner gear ring 20 together.

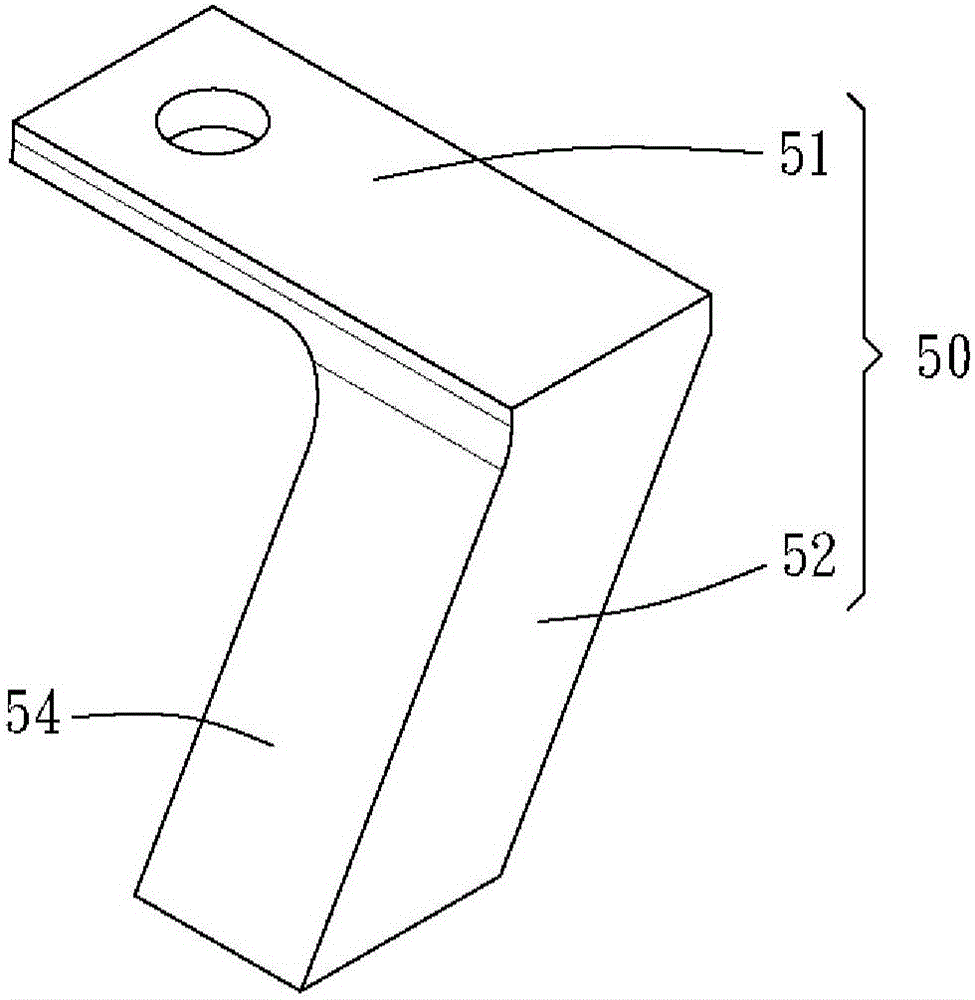

[0033] Such as figure 2 and Figure 7 As shown, the wave generator 40 has a bearing 41 , an elliptical wheel 42 , and a coupling 43 . The bearing 41 is set in the flexible outer gear cup 30, the elliptical wheel 42 is set in the bearing 41, the coupling 43 and the elliptical wheel 42 are assembled together through an adapter plate 44, and the two opposite sides of the adapter plate 44 are respectively There are two opposite first protrusions 45 and two opposite second protrusions 46, one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com