Safety protection device for pipeline

A technology of safety protection device and pipeline, which is applied in the direction of coupling, gas treatment, mechanical equipment, etc., to achieve the effect of practical convenience, simple structure and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

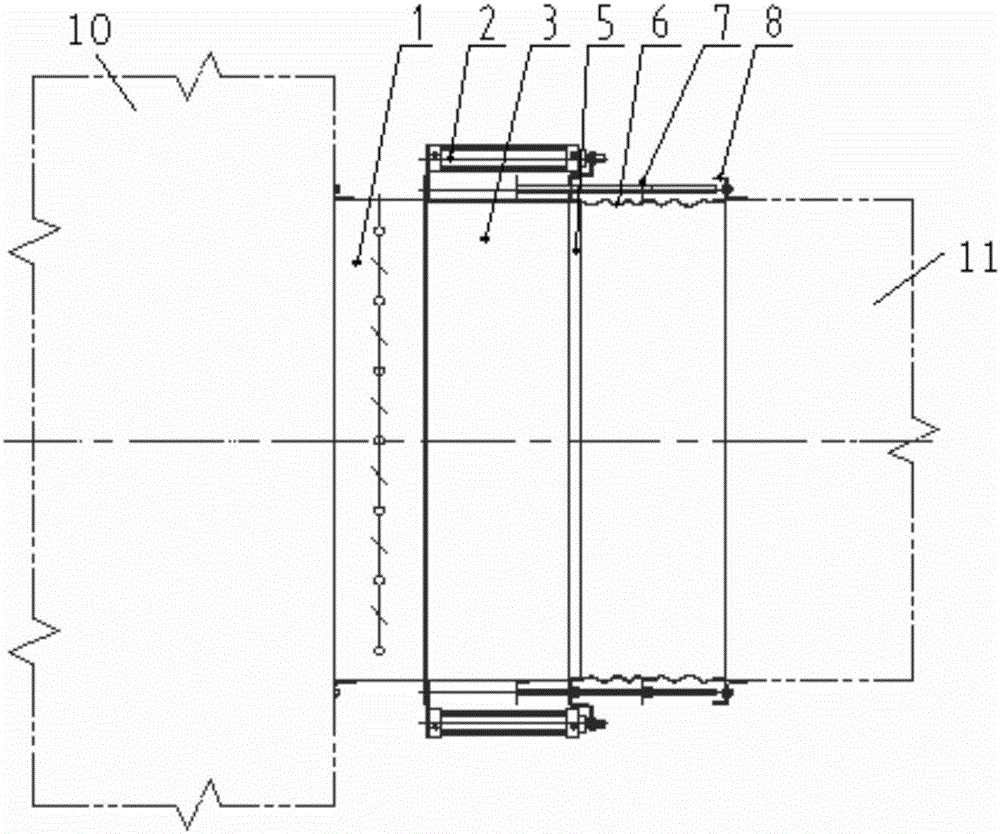

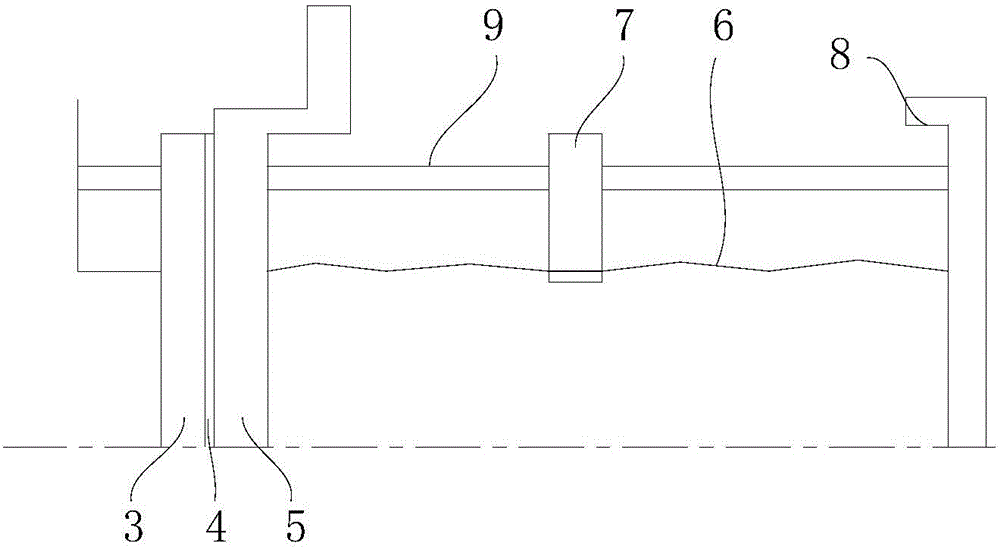

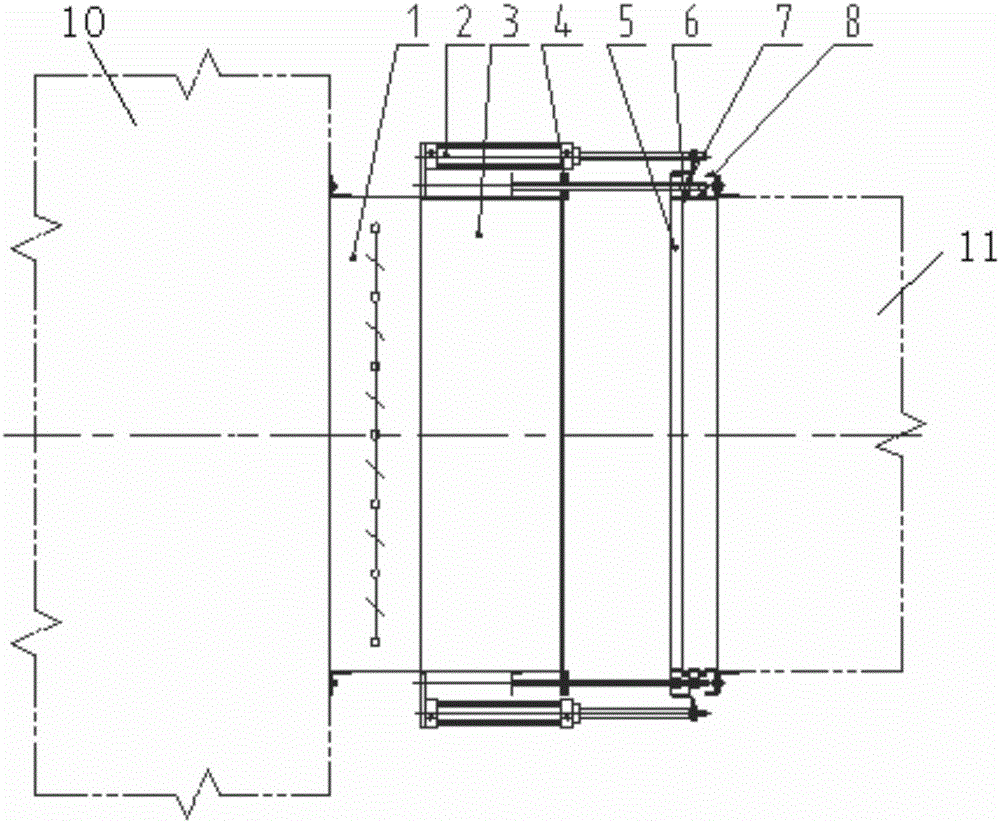

[0025] see Figure 1 to Figure 4 , the pipeline safety protection device in the illustration is a preferred embodiment of the present invention, specifically including a pneumatic damper 1, a cylinder 2, a fixed mounting seat 3, a sealing strip 4, a moving flange 5, a fireproof soft cloth 6, and a reinforcing flange 7 , Fixed flange 8 and guide rod 9 and other components. The pipeline safety protection device of this embodiment is installed on the air inlet pipeline of the VOCs exhaust gas adsorption device, and is connected to the place or the drainage fan that generates VOCs gas through the pipeline 11. It is collected into a closed container through pipelines for adsorption. The pneumatic air valve 1 is installed at the air inlet of the airtight container 10, and then the pipeline 11 is detachably connected to the air inlet of the pneumatic air valve 1 through the flexible fireproof connecting pipe 6. The flexible fireproof connecting pipe 6 Quick disconnect and connect fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com