Shale porosity measurement method

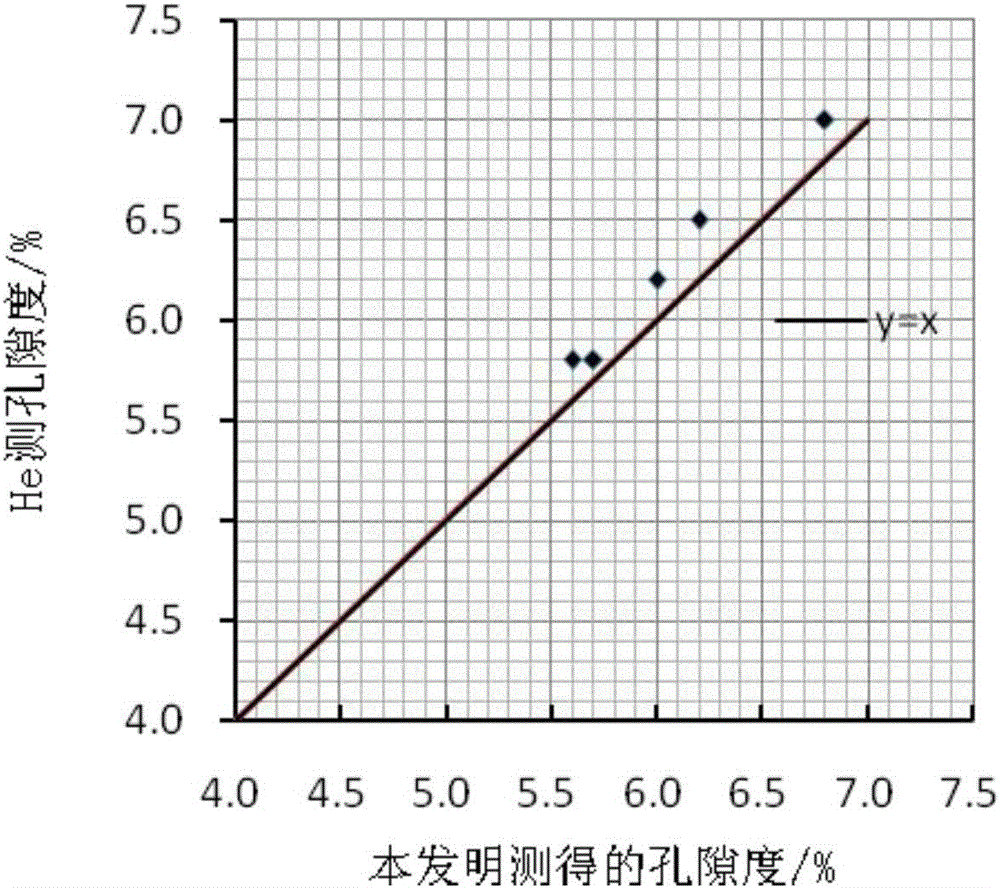

A technology of shale porosity and measurement method, which is applied in the field of shale porosity measurement and can solve problems such as inaccurate measurement of shale porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

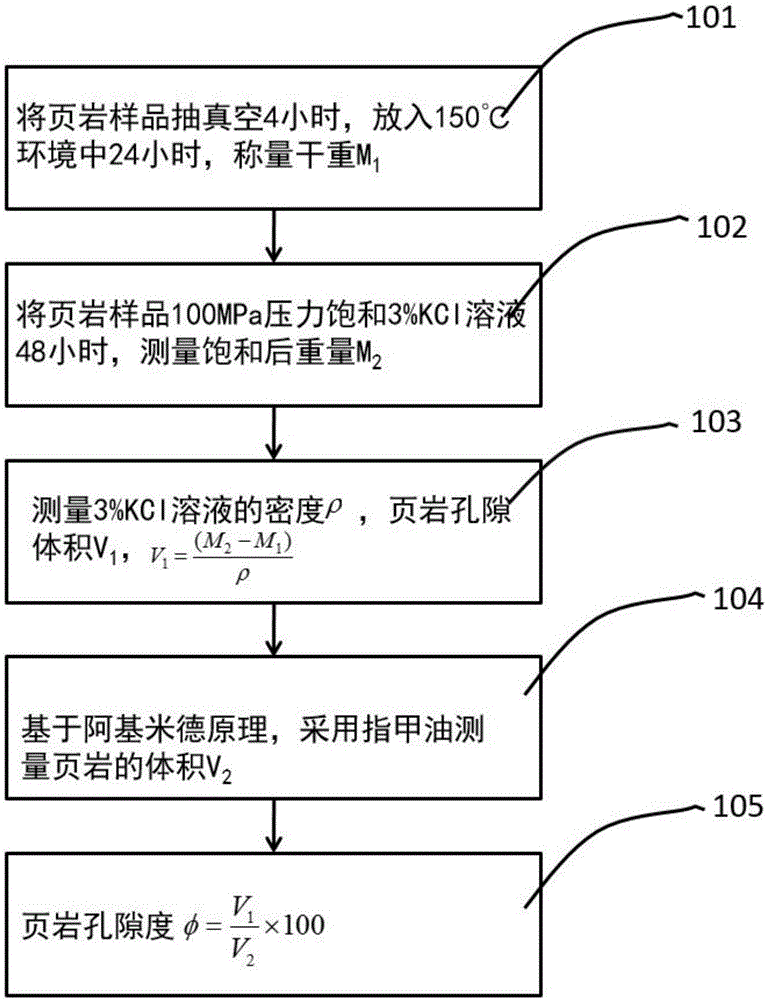

[0018] Follow the steps below to perform a shale porosity measurement:

[0019] Step (1): Select a certain amount of massive shale samples, put the shale samples in a vacuum environment at 150°C for 24 hours, and weigh the dry weight M 1 (33.4588g).

[0020] Step (2): Vacuumize the shale for 4 hours (vacuum degree reaches 0.1MPa), pressurize and saturate 3% KCl solution for 48 hours, the saturation pressure is 100MPa, measure the weight M after saturation 2 (33.6540g)

[0021] Step (3): measure the density ρ of 3% KCl solution, concrete measuring method is: measure the 3% solution of certain amount volume three times (2.1ml, 3.9ml, 3.4ml) with graduated cylinder, weigh its quality respectively with balance 2.2563g, 4.0709g, 3.6045g), using the formula Get the density measured 3 times, take the average value to get the density of 3% KCl solution is 1.06g / cm 3 .

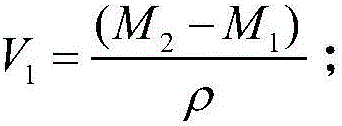

[0022] Step (4): Through the formula The pore volume of the obtained shale is 0.18cm 3 .

[0023] Step (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com