A safety protection system for down belt conveyor

A belt conveyor, safety protection technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of speeding and acceleration, and achieve the effect of avoiding speeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

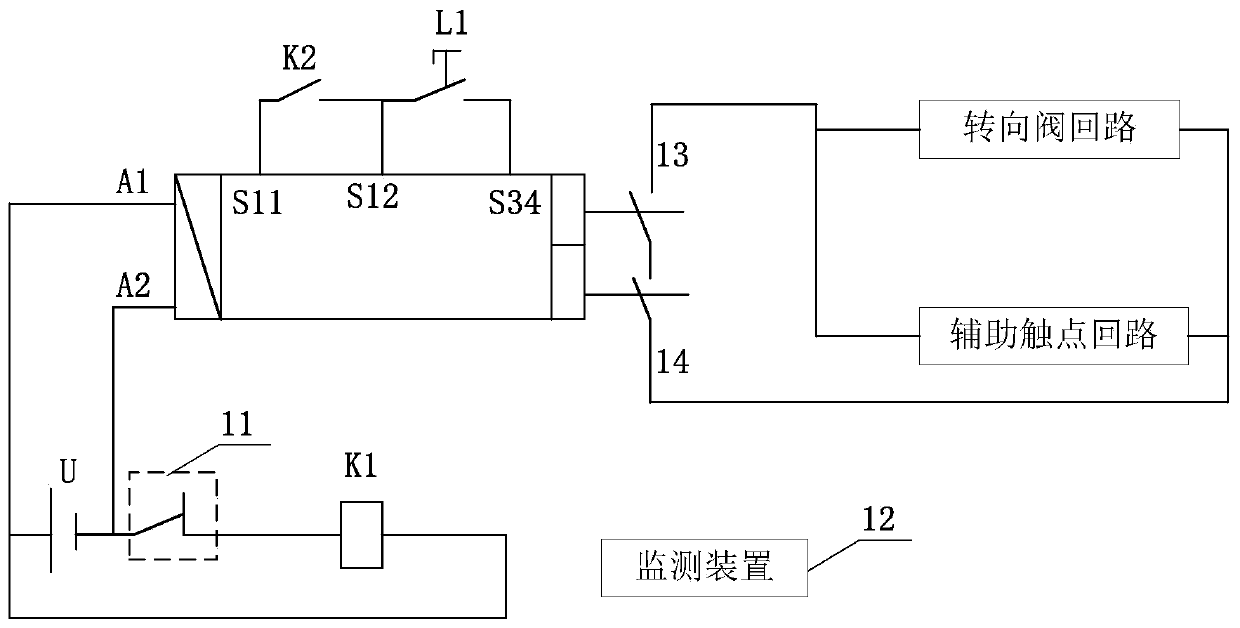

[0025] This embodiment provides a safety protection system for a belt conveyor, see figure 1 , showing its structural schematic diagram, including: speed switch, relay, safety relay and DC power supply U, wherein,

[0026] The DC power supply U, the normally closed contact 11 of the speed switch and the coil K1 of the relay are connected in series to form a signal input loop;

[0027] The input channel of the safety relay is connected to the normally open contact K2 of the relay, the DC power input channel of the safety relay is connected to the DC power U, and the normally open contact channels of the safety relay are respectively connected in series to the Describe the steering valve circuit of the brake hydraulic system of the down conveyor and the auxiliary contact circuit of the brake pump motor contactor;

[0028] The monitoring device 12 of the speed switch monitors the belt speed of the down belt conveyor, and controls the normally closed contact 11 to open when the b...

Embodiment 2

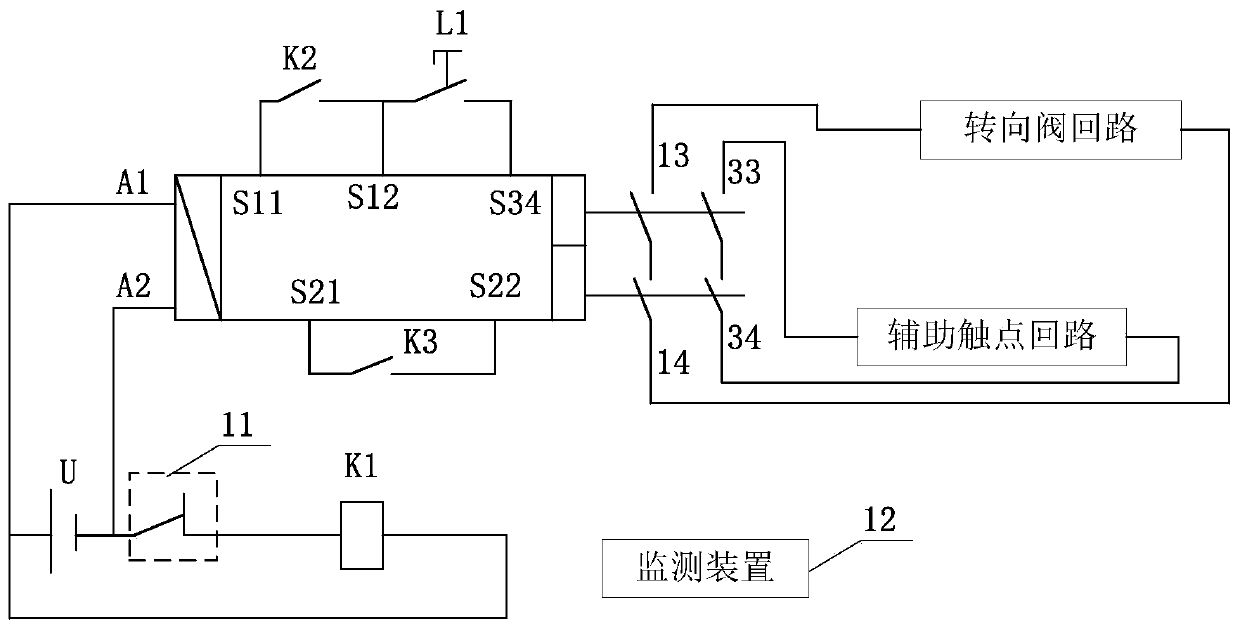

[0032] This embodiment provides another safety protection system for a down belt conveyor, see figure 2 , shows a schematic structural diagram of the system, wherein the safety relay is a dual-channel safety relay, that is, the safety relay includes two input channels, wherein one input channel is composed of terminal S11 and terminal S12, and the relay is connected between S11 and S12 The normally open contact K2 of the safety relay; the other input channel is composed of terminal S21 and terminal S22, and the normally open contact K3 of the relay is connected between S21 and S22; the normally open contact channel of the safety relay also includes two, one normally open The contact channel is composed of terminal 13 and terminal 14, and terminal 13 and terminal 14 are connected in series in the steering valve circuit of the brake hydraulic system; the other normally open contact channel is composed of terminal 33 and terminal 34, and terminal 33 It is connected in series wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com