Method for building carbon fiber enhanced composite material milling force prediction model

A technology of reinforced composite materials and predictive models, which is applied in the field of mechanical cutting and processing, and can solve problems such as insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

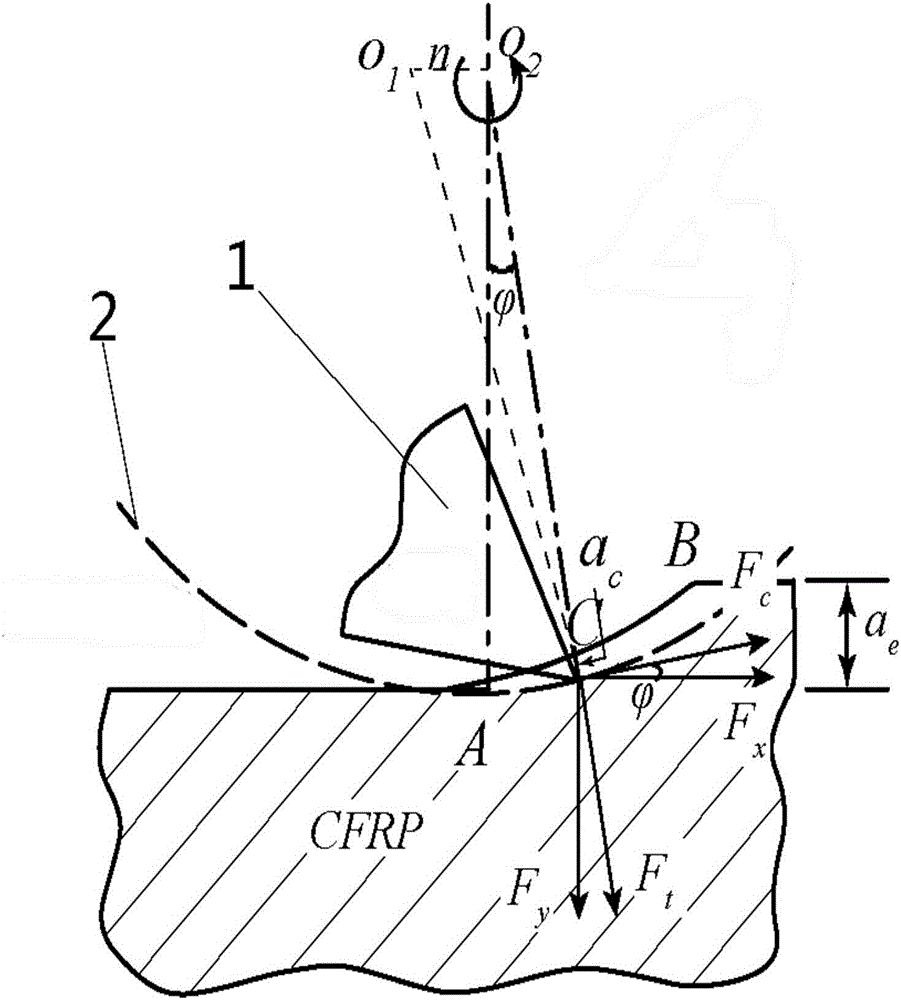

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 comprises the following steps:

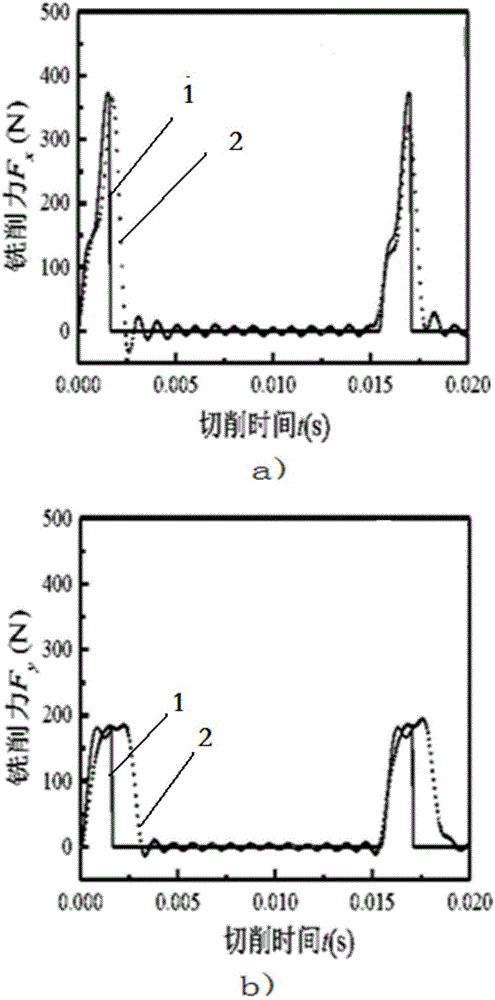

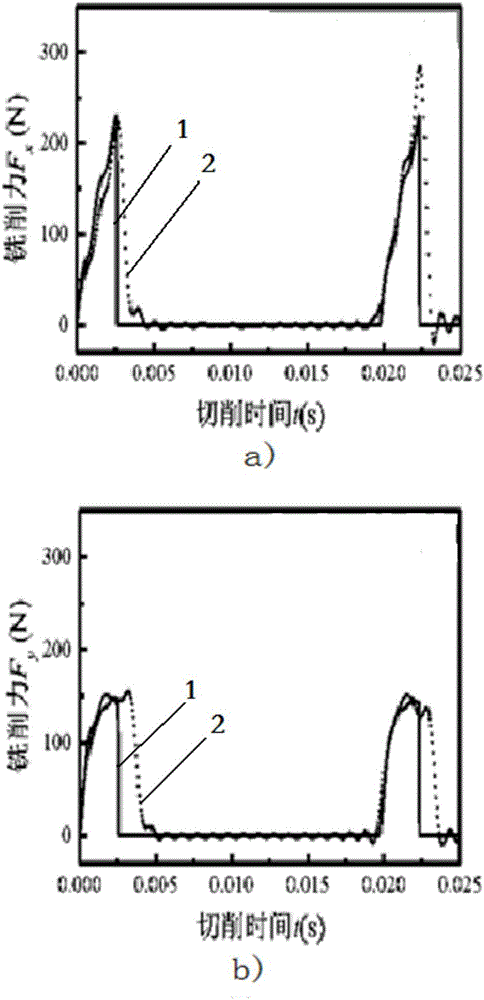

[0055] The first step is to obtain the milling force coefficient. According to the above experimental parameters and settings, the milling experiment was carried out on the carbon fiber reinforced composite unidirectional plate. The processing method was side milling, and the milling force data under different parameters were obtained. The cutting force curve in the cutting stage corresponds to the theoretically calculated cutting process, so the cutting force corresponding to each cutting position can be extracted according to the cutting force signal curve. According to the formula 1-11, the cutting position corresponding to the cutting force data point can be calculated, and the K corresponding to the fiber cutting angle, cutting speed and instantaneous cutting area can be calculated c and K t , a total of 3720 groups of effective milling force data points were obtained.

[0056] In the second step, the BP neural netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com