Product quality accident classification method based on failure mechanism and domain mapping

A technology of product quality and failure mechanism, applied in the field of quality management, can solve problems such as insufficient utilization of big data, detection, prevention and control of adverse accidents, and the development of quality risk early warning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

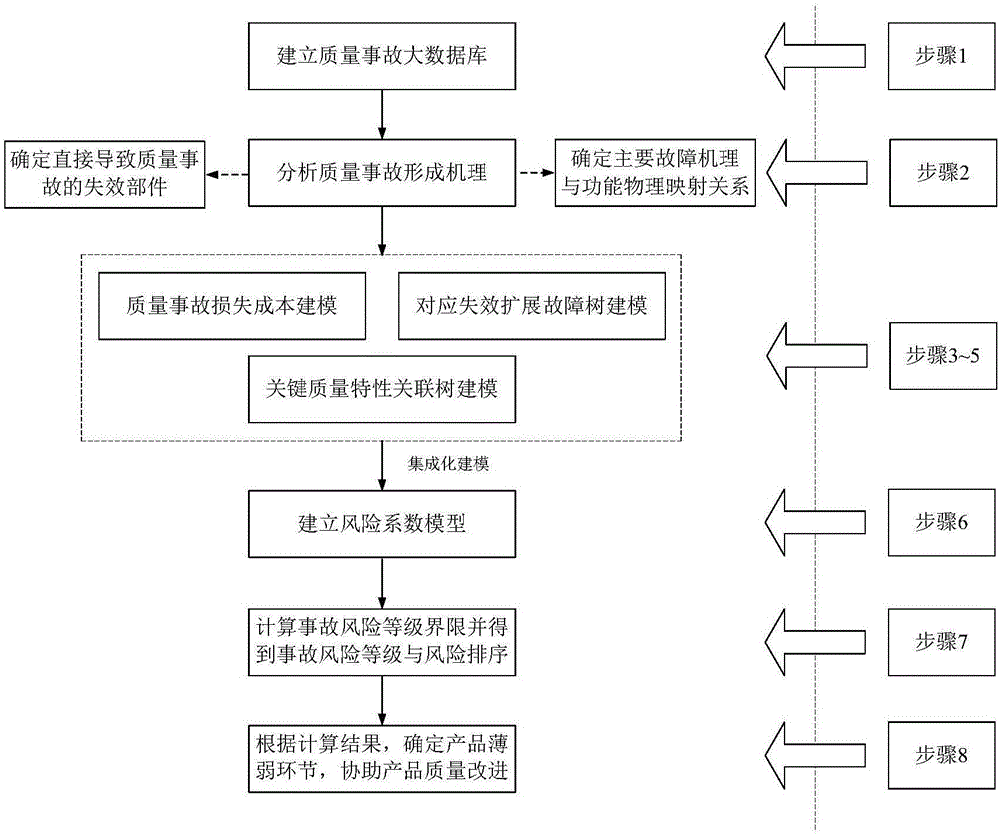

[0056] The present invention is a product quality accident classification method based on fault mechanism and inter-domain mapping, see figure 1 As shown, the steps are as follows:

[0057] Step 1 Establish a large database of quality accidents

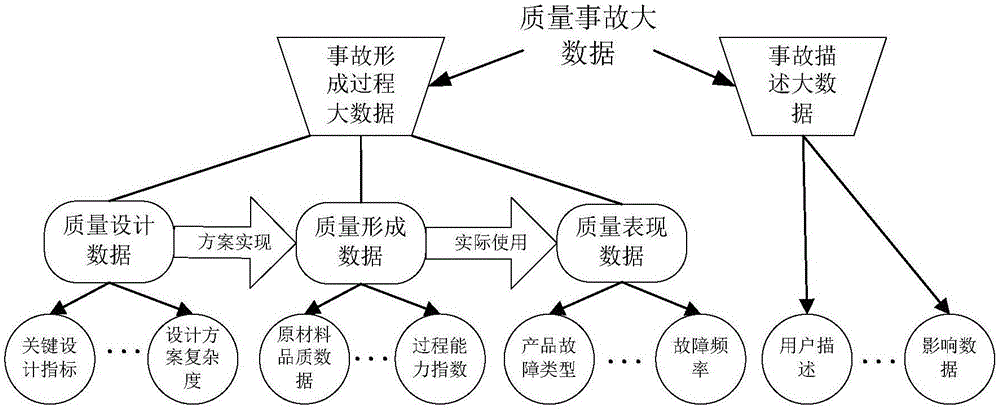

[0058] Collect the big data of quality accidents caused by the alarm failure of the computer board of a CNC hydraulic equipment. Determine the relevant data describing product quality evolution and accident impact from the design and manufacturing department of the enterprise, user feedback, and third-party accident reports, and classify and form a large quality accident database, such as figure 2 shown.

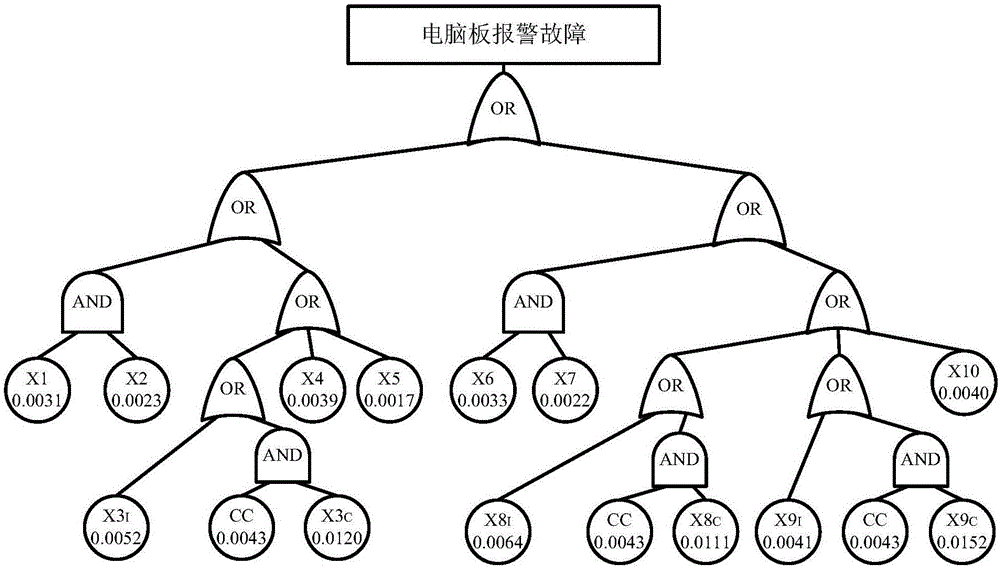

[0059] Step 2 Analyze the formation mechanism of quality accidents, determine the failed components that directly lead to quality accidents, the main failure mechanism that causes the failure of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com