Composite graphite grounding wire

A technology of composite graphite and graphite wire, applied in the direction of connecting contact materials, carbon-silicon compound conductors, root rods/rods/wires/strip conductors, etc., can solve the problem of losing the lightning protection function, unable to withstand the huge lightning current, and graphite grounding surface Small problems, to achieve the effect of fast conductive transmission of graphite wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

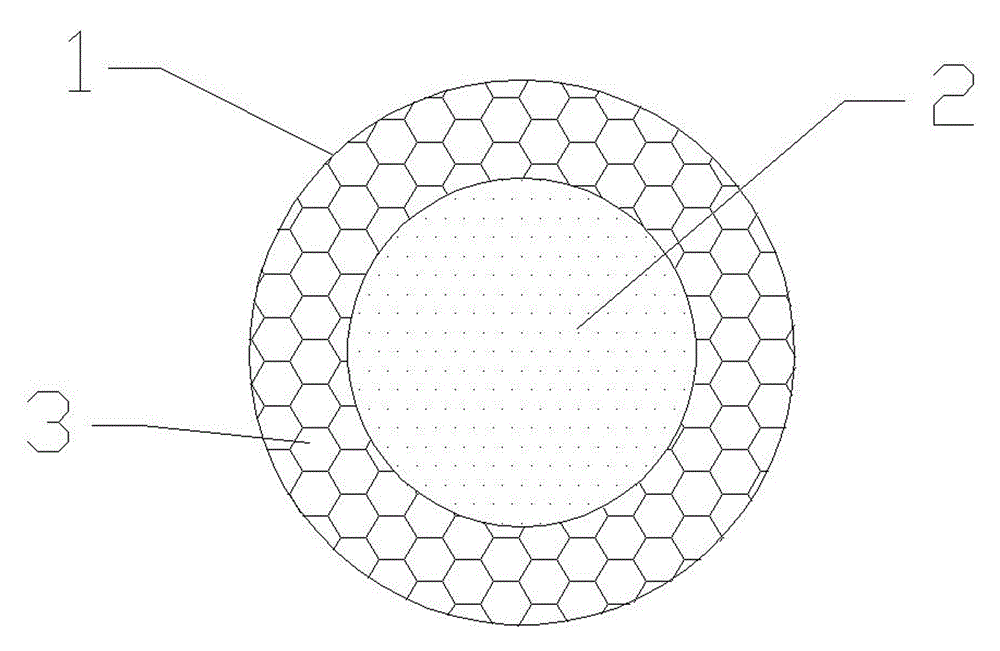

[0014] Such as figure 1 Shown: a composite graphite grounding wire, including a graphite wire body 1, characterized in that: a corrosion inhibitor 2 is provided in the middle of the graphite wire body 1, and graphite wire 3 is braided on the outer ring of the corrosion inhibitor 2.

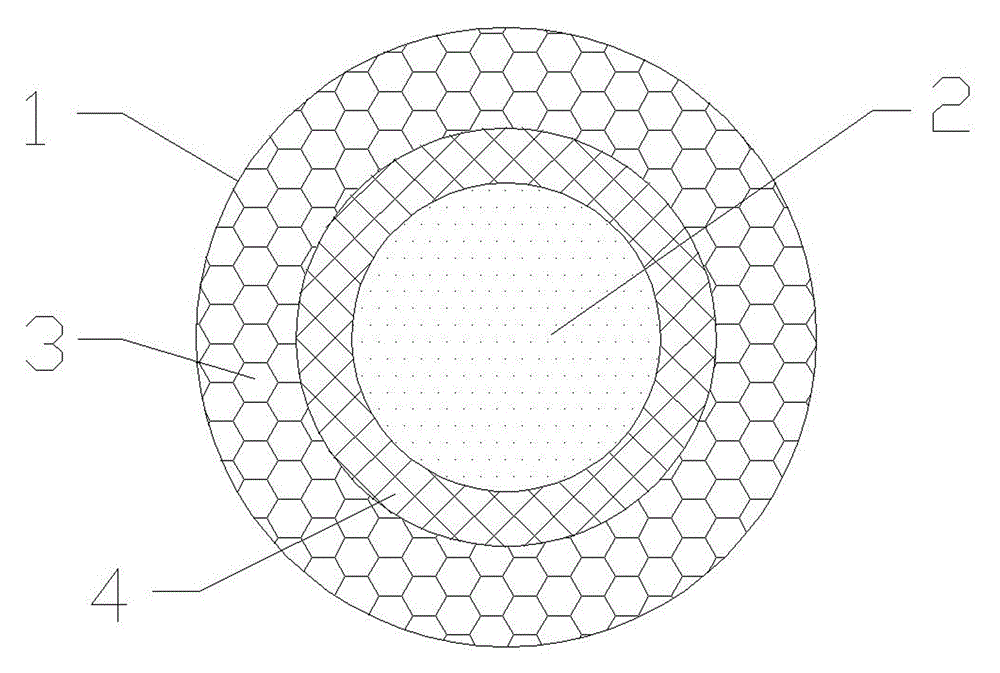

[0015] Further speaking: the outer ring of the corrosion inhibitor 2 is provided with a circle of metal mesh 4, and the outer ring of the metal mesh 4 is woven with graphite wire 3.

[0016] Further speaking: the metal mesh 4 is made of carbon fiber metal material.

[0017] When in use: connect the graphite wire body 1 to the ground, use the volatilization of the corrosion inhibitor 2 to keep the ground moist, and improve the conductivity of the graphite wire body 1. Since the corrosion inhibitor 2 volatilizes slowly, thereby increasing its volatilization time, Since the outer ring of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com