High-reliability lithium battery cap

A reliability and lithium battery technology, applied in secondary batteries, battery components, circuits, etc., can solve problems such as unreliable operation, unreliable judgment of battery internal pressure, and increased costs, so as to achieve high utilization and prevent battery failure. The effect of scrapping and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A cylindrical high-rate lithium-ion battery welded with end faces of the present invention will be further described in detail below in conjunction with specific implementation examples and accompanying drawings.

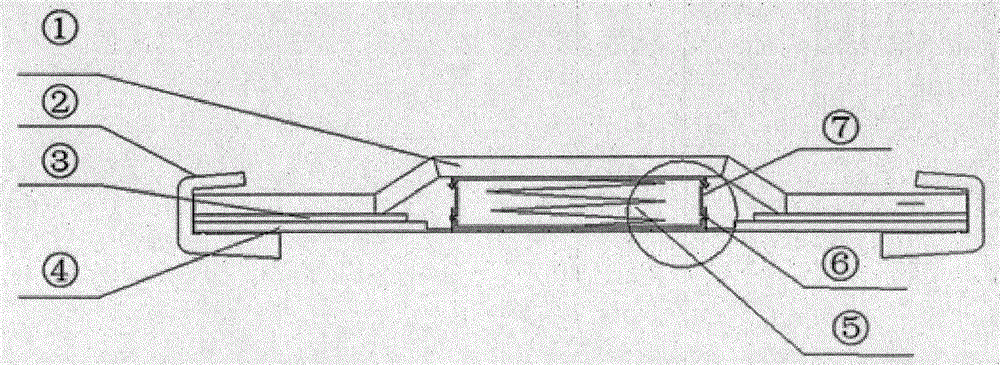

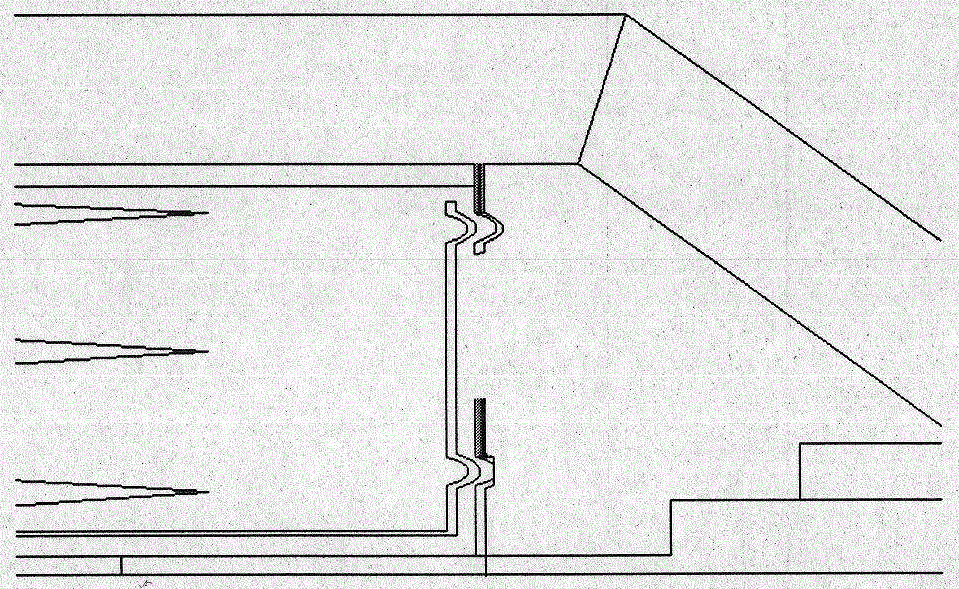

[0021] The spring (5) connects the explosion-proof body (7) and the upper cover (1), the lower end is connected with the explosion-proof body (7) (the middle movable conductive part) by welding, the upper end and the upper cover (1) are bonded by rubber, and the upper conductor (6) On the upper cover, it is a part of the upper cover protrusion, and the lower conductor (6) is on the orifice plate, which is a part of the orifice plate (4) protrusion, and the orifice plate (4) has an insulating gasket ( 3), there is an upper cover (1) on the insulating gasket (3), the three are placed concentrically, and are connected by insulating glue. The explosion-proof body (7) is between the upper cover (1) and the orifice plate (4), and It is tightly combined with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com