A kind of iron-based nano-array electrocatalytic electrode, its preparation method and alkaline fuel cell

A nano-array and electrocatalytic technology, applied in the direction of fuel cells, battery electrodes, nanotechnology, etc., can solve the problems of electrochemical performance attenuation, and achieve the effects of reducing production costs, improving oxygen reduction catalytic activity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

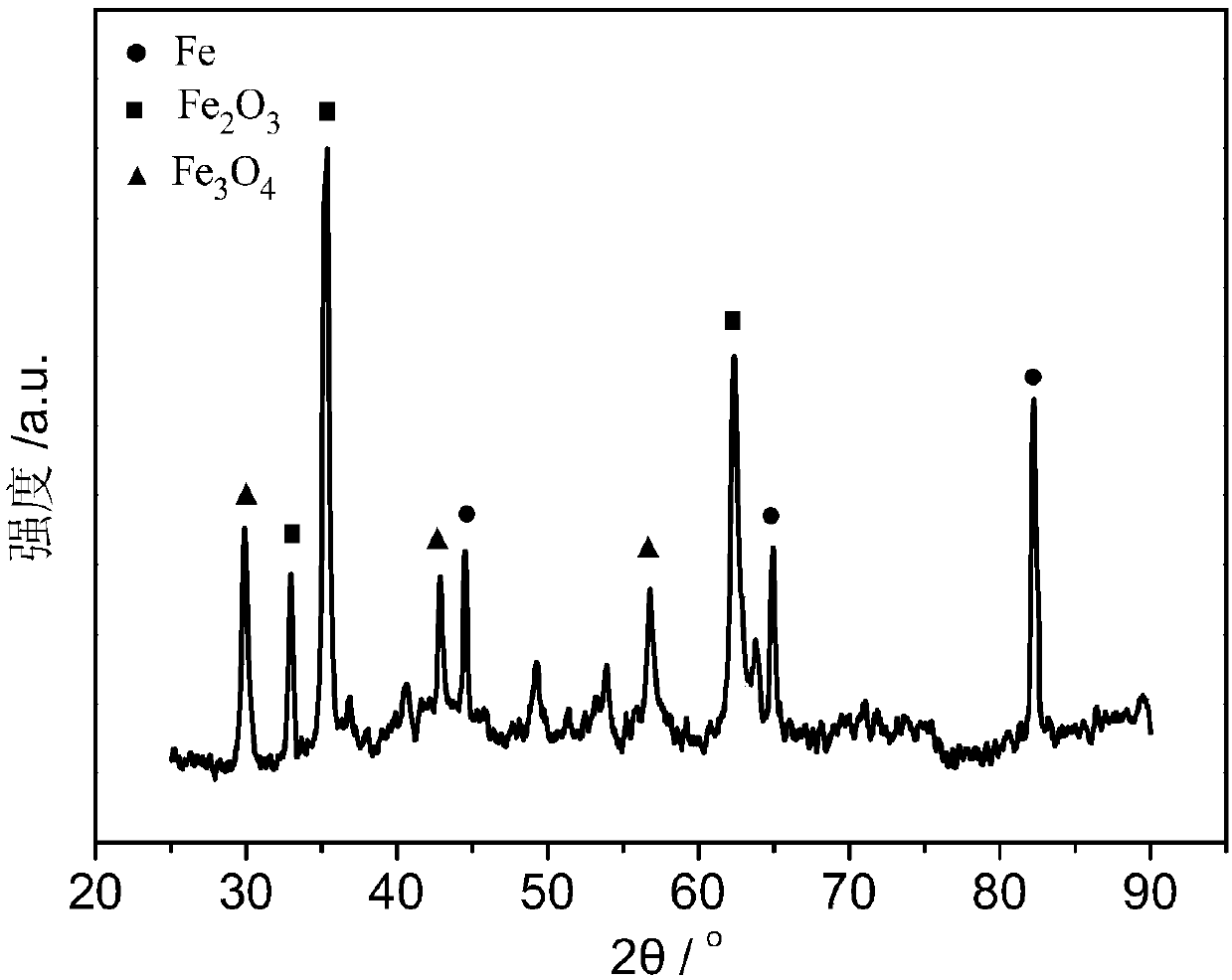

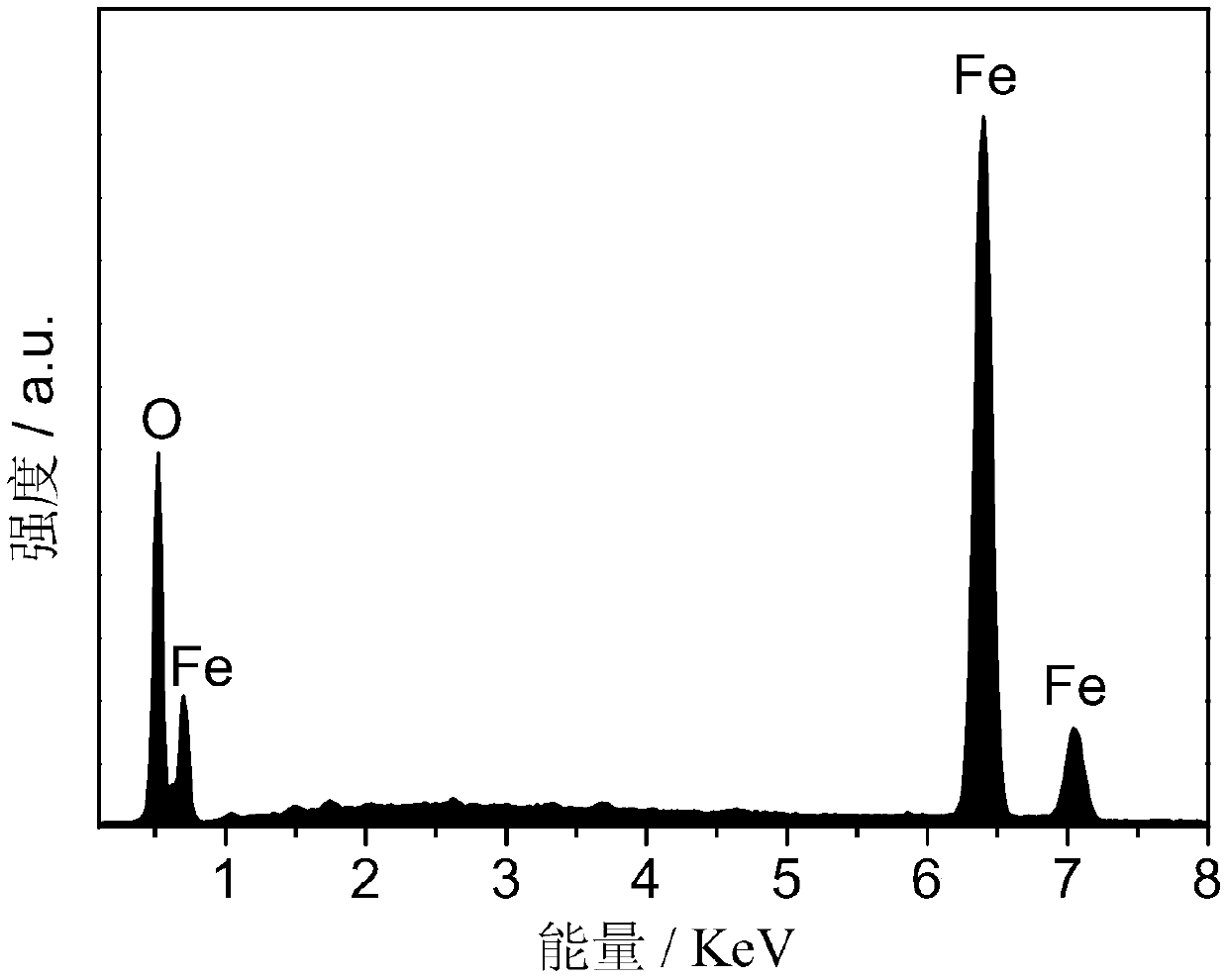

Image

Examples

Embodiment 1

[0053] A method for preparing an iron-based nano-array structure electrocatalytic electrode, comprising the steps of:

[0054] (1) Polish the surface (10mm×20mm) of the 0.2mm pure iron sheet (99.99%) with 1000, 1500 and 2000 mesh sandpaper in turn, and polish with 0.3 and 0.05μm alumina polishing powder to make the surface of the electrode substrate basically flat, and then Ultrasonic in ethanol and distilled water for 10min (ultrasonic power is 200W), take out and dry as the anode for anodic oxidation, the counter electrode is a copper sheet, and the electrolyte contains 0.2wt% NH 4 F, the ethylene glycol solution of 5.0vol% perchloric acid, the oxidation voltage is 60V, the oxidation temperature is 20°C, and the oxidation time is 10min to obtain the electrode matrix;

[0055] (2) The electrode matrix is used as the anode, and the pure copper sheet is used as the counter electrode, and the anodic oxidation is carried out, and the electrolyte used for the anodic oxidation is...

Embodiment 2

[0060] A method for preparing an iron-based nano-array structure electrocatalytic electrode, comprising the steps of:

[0061] (1) Polish the surface (10mm×20mm) of a 0.5mm pure iron sheet (99.99%) with 1000, 1500 and 2000 mesh sandpaper in sequence, and then further polish to make the surface of the substrate basically flat, and then ultrasonically in ethanol and distilled water for 10min (Ultrasonic power is 180W), take out and dry and carry out anodic oxidation treatment as anode, with pure copper sheet as counter electrode, anodic oxidation treatment adopts to contain 0.3wt%NH 4 F. The ethylene glycol solution of 5.0vol% perchloric acid is used as the electrolyte, the oxidation voltage is 50V, the oxidation is carried out at 30°C, and the oxidation time is 20min to obtain the electrode matrix;

[0062] (2) The electrode substrate is used as the anode, and the counter electrode is a pure copper sheet, which is subjected to electrochemical anodic oxidation treatment, using 0...

Embodiment 3

[0065] A method for preparing an iron-based nano-array structure electrocatalytic electrode, comprising the steps of:

[0066] (1) Polish the surface (10mm×20mm) of a 0.5mm pure iron sheet (99.99%) with 1000, 1500 and 2000 mesh sandpaper in sequence, and then further polish to make the surface of the substrate basically flat, and then ultrasonically in ethanol and distilled water for 10min (Ultrasonic power is 250W), after taking out and drying, carry out electrochemical anodizing treatment as anode, with pure copper sheet as counter electrode, anodic oxidation adopts to contain 0.4wt%NH 4 F. The ethylene glycol solution of 3.0vol% perchloric acid is used as the electrolyte, the oxidation voltage is 40V, the reaction temperature is 40°C, and the oxidation time is 20min to obtain the electrode matrix;

[0067] (2) The electrode substrate is used as the anode, and the pure copper sheet is used as the counter electrode for electrochemical anodic oxidation treatment, and the anodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com