Processing method of circuit board protective film

A processing method and technology of protective film, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary processing, etc., can solve the problems of wasting labor, low work efficiency, troublesome operation, etc., saving labor, improving work efficiency, eliminating The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

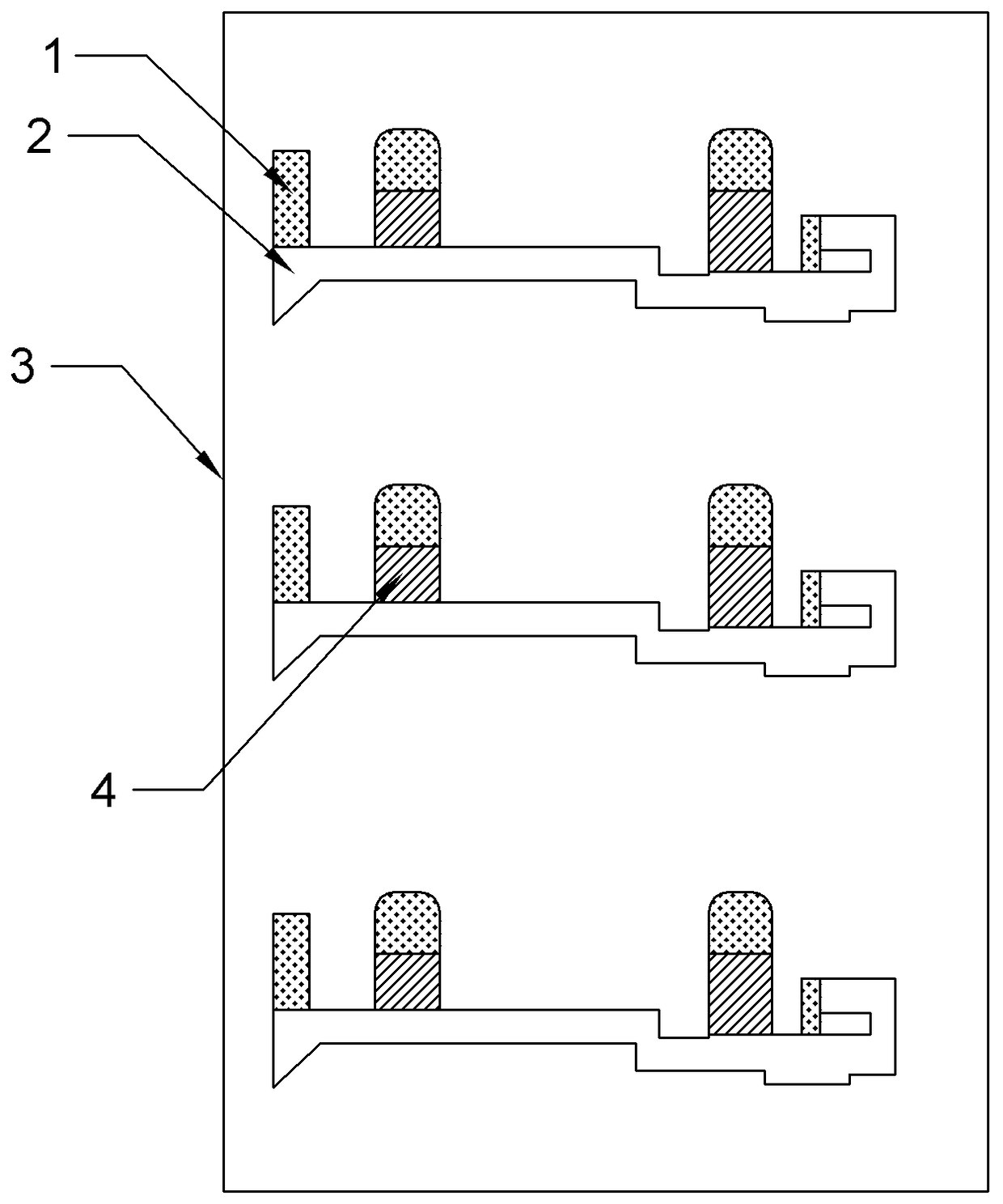

Image

Examples

Embodiment

[0023] Embodiment: the processing method of circuit board protective film, comprises the following steps:

[0024] The first step is to use two first rollers to feed the raw materials of black glue and blue film respectively, wherein the black glue is pasted with release paper, and the black glue is located on the top of the blue film, and then the blue film and black film are simultaneously The glue is sent to the middle of the second roller, the blue film and the black glue are pressed together, and the air between the blue film and the black glue is evacuated. Wrap the end of the release paper around the third roller and move it counterclockwise. The black glue and other parts of the blue film continue to move forward. The release paper on the black glue is separated from the black glue, exposing the black glue away from the blue film. Rubber surface. At the same time, the release paper is fed above the black glue to form an anti-adhesive layer on the black glue. The black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com