High-temperature baking sterilizer

A sterilizer and high-temperature technology, applied in heating and other directions, can solve the problems of inability to sterilize different strains, limited use range of steam high-temperature sterilizers, and reduced use efficiency of sterilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

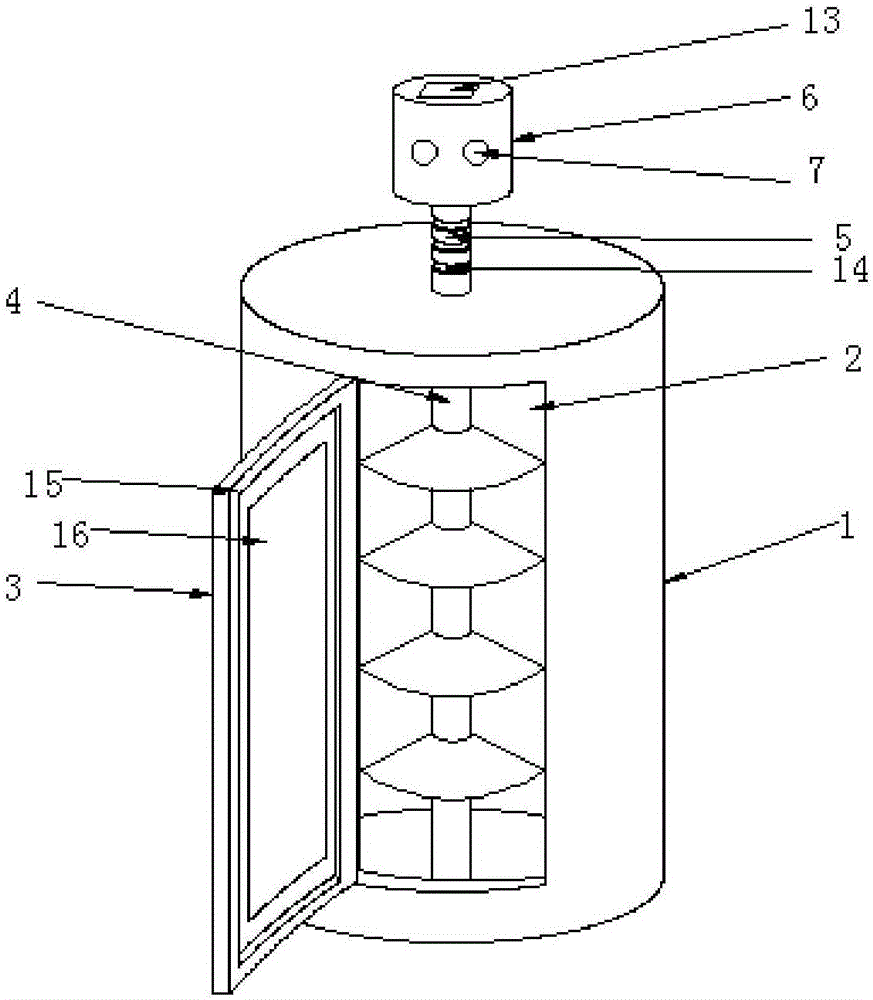

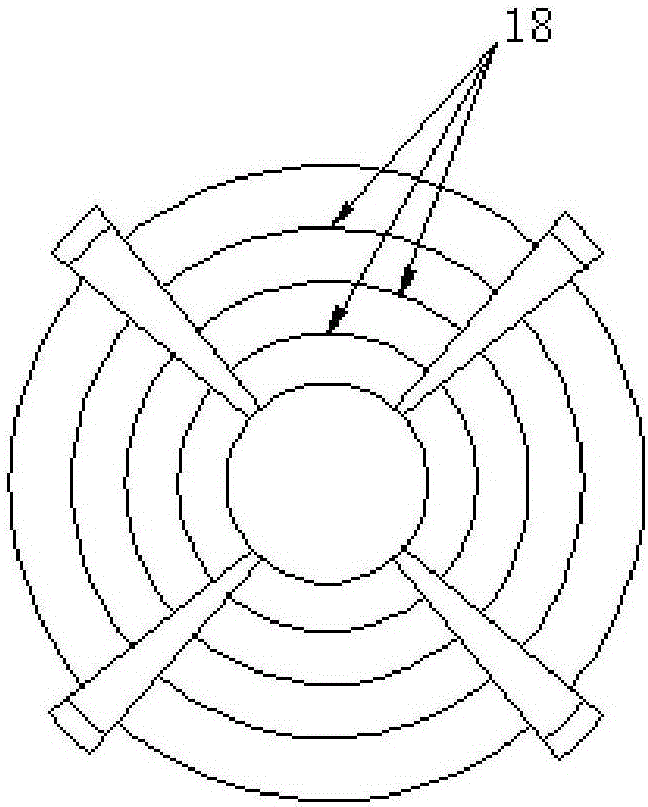

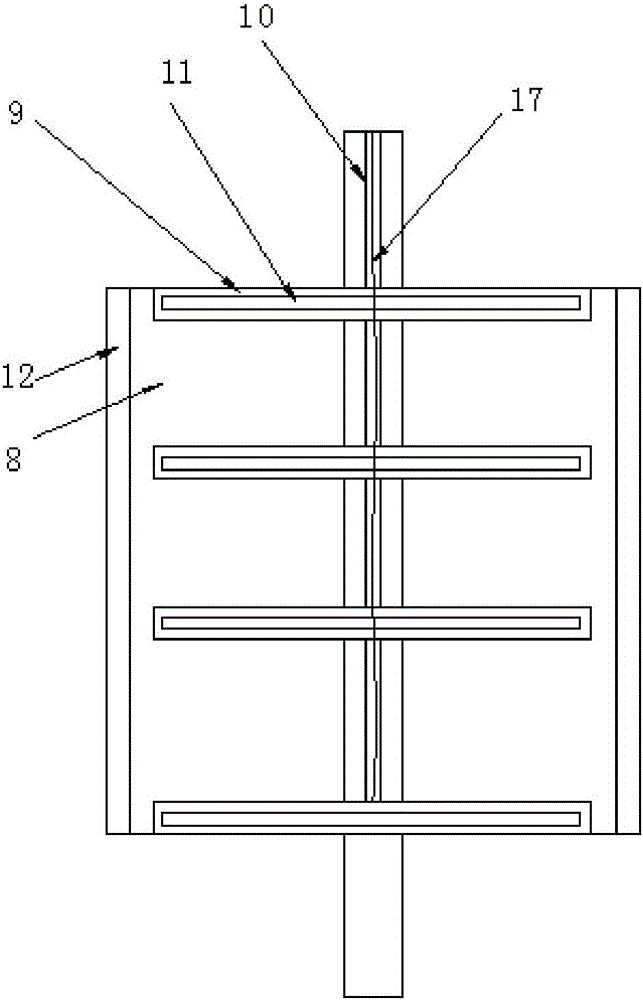

[0018] see as Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a drying box shell 1, a material inlet and outlet 2, a sealed door 3, a rotating shaft 4, a pull shaft 5, an electrical box 6, a switch knob 7, and a partition 8. Place the plate 9; the front side of the drying box shell 1 is provided with a feed and discharge port 2, and one side of the feed and discharge port 2 is screwed with a sealed door 3 through a hinge; the bottom end of the rotating shaft 4 It is screwed to the bottom of the drying box shell 1 through the bearing, and after the upper end of the rotating shaft 4 passes through the top of the drying box shell 1, it is connected with the pull shaft 5 through a coupling, and the top of the pull shaft 5 is connected by a fixing screw There is an electrical box 6, the outer wall of the electrical bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com