Flexible intelligent pressing system

An intelligent and flexible technology, applied in the field of stamping systems, can solve the problems of flexible production of stamping parts that cannot be multi-variety, achieve good mechanical stability, break through limitations, and liberate the limitations of space and location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the present invention in more detail, the following system example is given. However, the scope of the present invention is not limited thereto.

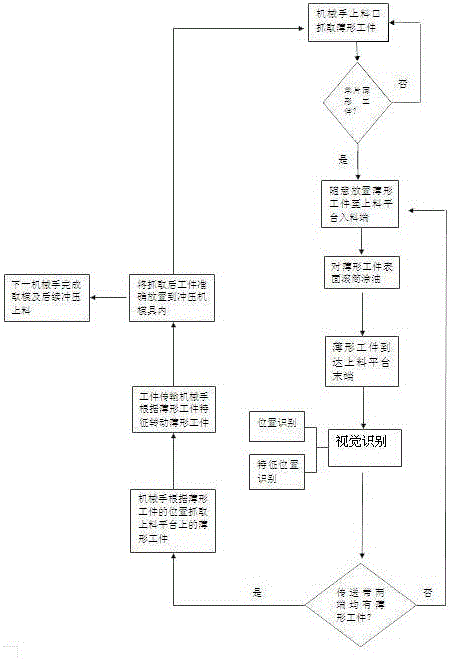

[0024] refer to figure 1 , a flexible intelligent stamping system, which is equipped with a workpiece transfer manipulator to grasp and position thin workpieces, transfer and move, and place and unload; the stamping system includes the following stamping steps:

[0025] A. Grabbing and loading, thin workpieces are stacked at the feeding port, and the workpiece transfer manipulator grabs the thin workpieces stacked on the feeding port, and randomly places them on the feeding end of the feeding platform;

[0026] B. The conveyor belt transports the thin workpieces grabbed by the workpiece transfer manipulator from the feeding end of the loading platform to the end of the loading platform for visual recognition;

[0027] C. Visual recognition, set the visual detection camera above the loading platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com