A special loading vehicle for horizontal reaction tank

A technology for feeding trucks and reaction tanks, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of workers' personal safety threats, high labor intensity, and unfavorable safety production, and achieve low labor intensity and space utilization. High and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

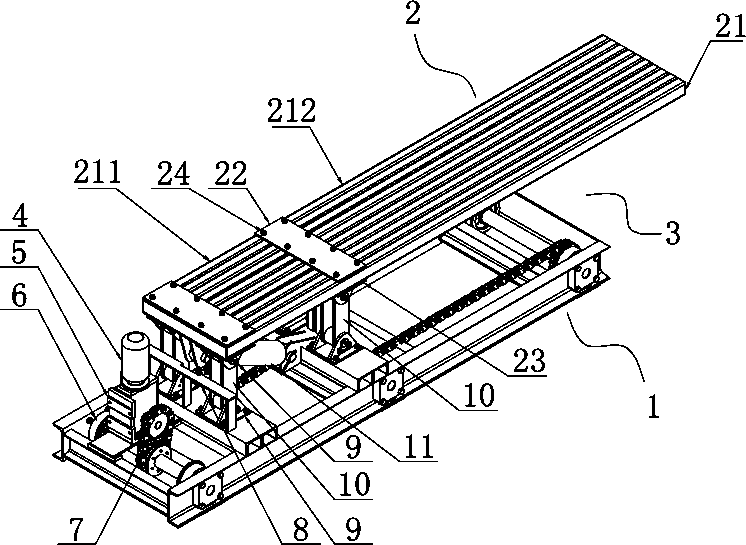

[0017] Such as figure 1 As shown, the special feeding car for the horizontal reaction tank of the present invention includes a chassis 1, and a running mechanism of the feeding car is installed on the chassis, and the running mechanism includes a driving motor 4, a speed reducer 5, a transmission device 7 and a walking wheel group, The walking wheel set is a track walking wheel set 6, and the transmission device is a chain and a sprocket transmission device. A loading platform 2 is arranged above the chassis, and the loading platform is divided into a connecting section 211 and a cantilever loading section 212 along the length direction of the tank body. In the link mechanism, each set of support arms is composed of at least two parallel single support arms, and a support arm hinge seat 9 for mounting the support arms is respectively provided on the connecting section between the chassis and the loading platform. The cantilever loading section is horizontally suspended above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com