The bypass valve capable of repeating switch

A technology of bypass valve and switch, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of long basket length, complex structure, expensive price, etc., and improve drilling efficiency. High efficiency, high sand cleaning efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

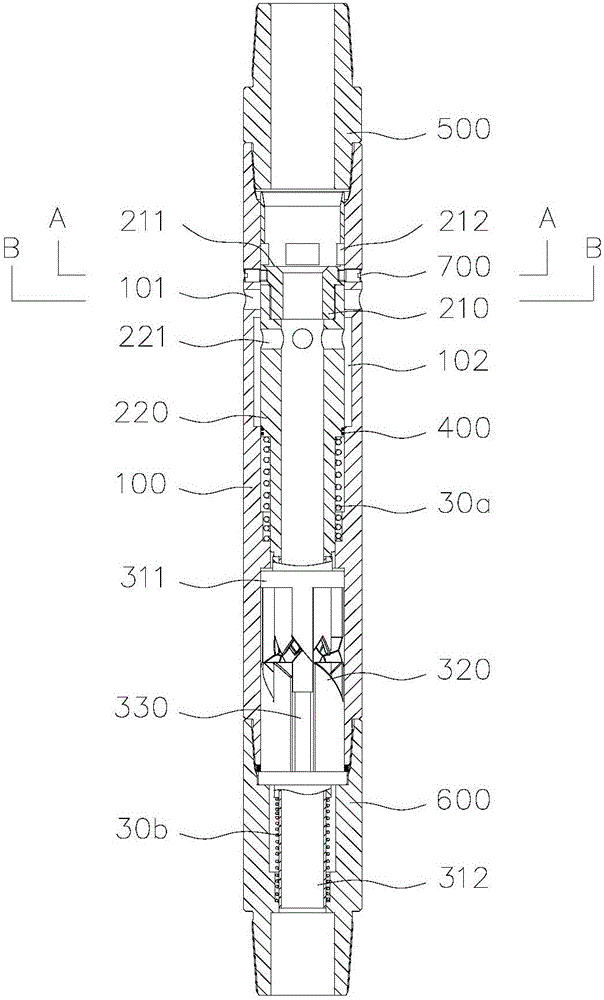

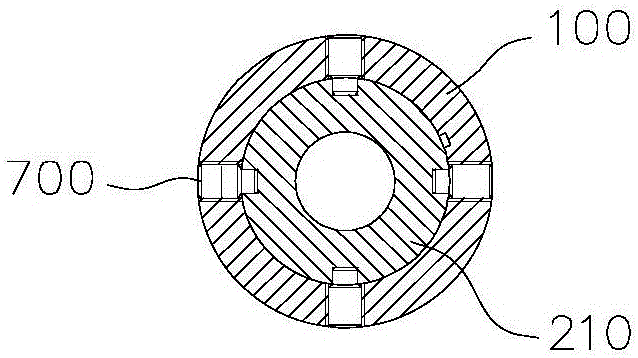

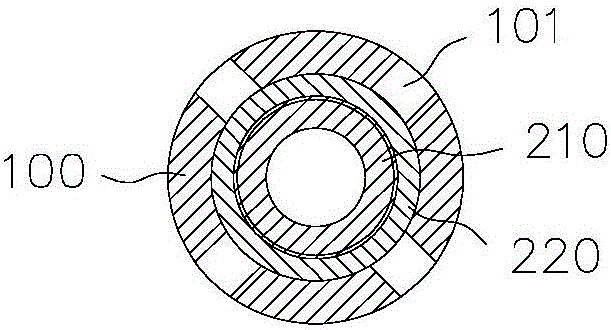

[0040] Such as figure 1 The bypass valve that can be switched repeatedly according to the present invention includes a valve body 100 and a valve core 200 that can slide in the valve body 100. The inner cavity of the valve body 100 forms an axially through main channel through the valve core 200, so The valve body 100 is sequentially provided with a bypass hole 101 and an inner ring groove 102 along its axial direction, and the valve core 200 is provided with a connecting channel, and the bypass hole 101 and the main channel are connected to form a bypass channel through the connecting channel. When the inner ring groove 102 and the main channel are connected through the connecting channel, a straight-through flow channel is formed. The valve body 100 is also equipped with a valve core connected to the valve core 200 and can position the valve core 200 to open the bypass channel. The reset mechanism for the position of the runner and straight-through runner.

[0041] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com