Water pump for nuclear power station plant

A technology for nuclear power plants and water pumps, which is applied to pumps, components of pumping devices for elastic fluids, pump control, etc., and can solve problems such as inconvenient maintenance of long-axis pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

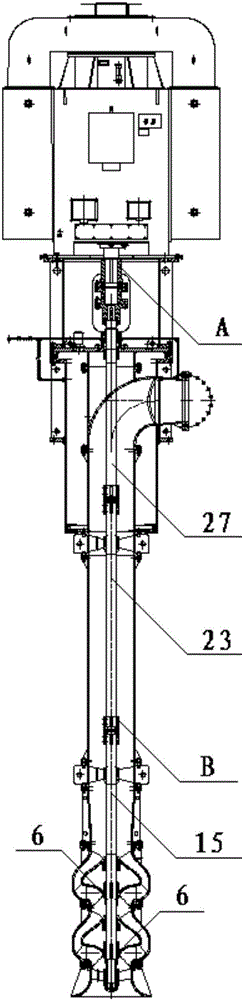

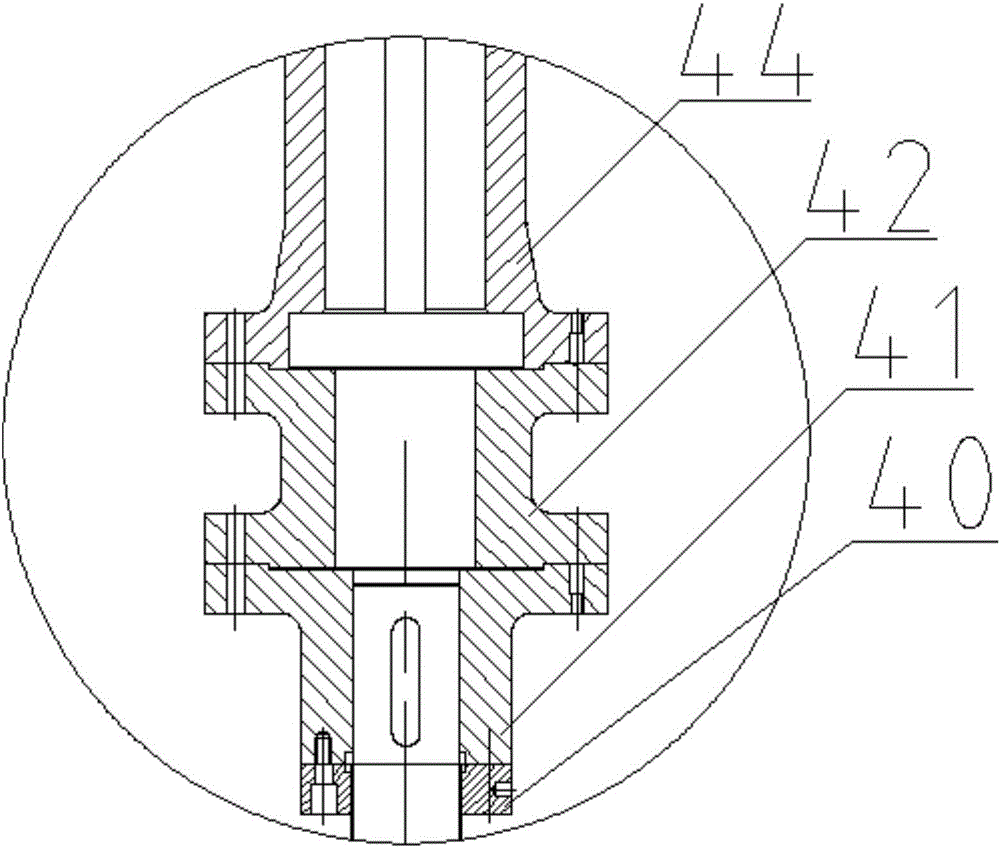

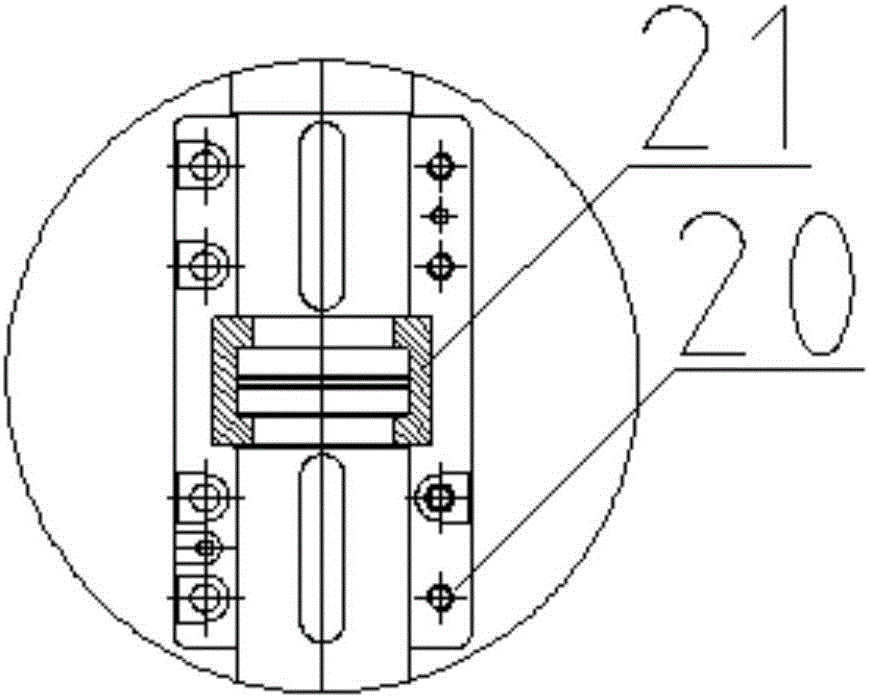

[0025] Such as figure 1 Shown is a schematic diagram of a nuclear power plant water pump of the present invention. The plant water pump for nuclear power plants includes a motor, a motor base, a pump base, a connecting pipe assembly, a diversion shell assembly, a water inlet horn, and a drive shaft assembly. The motor is installed on the motor base, the motor base is fixedly connected with the pump base through the pump cover, and the pump base is set on the pump pit, such as Figure 7 As mentioned above, the motor base of this solution is a cylindrical structure, the upper and lower ends of the cylindrical structure are provided with connecting flanges, and the interior of the cylindrical structure can provide installation space for the connecting assembly of the motor drive shaft and the upper main shaft. Such as Figure 5 As shown, the pump base of this scheme is a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com