Pneumatic control system for fire door

A pneumatic control system and technology for fire doors, applied in fire doors, fluid pressure actuators, servo motors, etc., can solve the problems that electrical circuits and electrical components are difficult to guarantee normal use, and are not suitable for electrical systems. Good safety protection effect, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

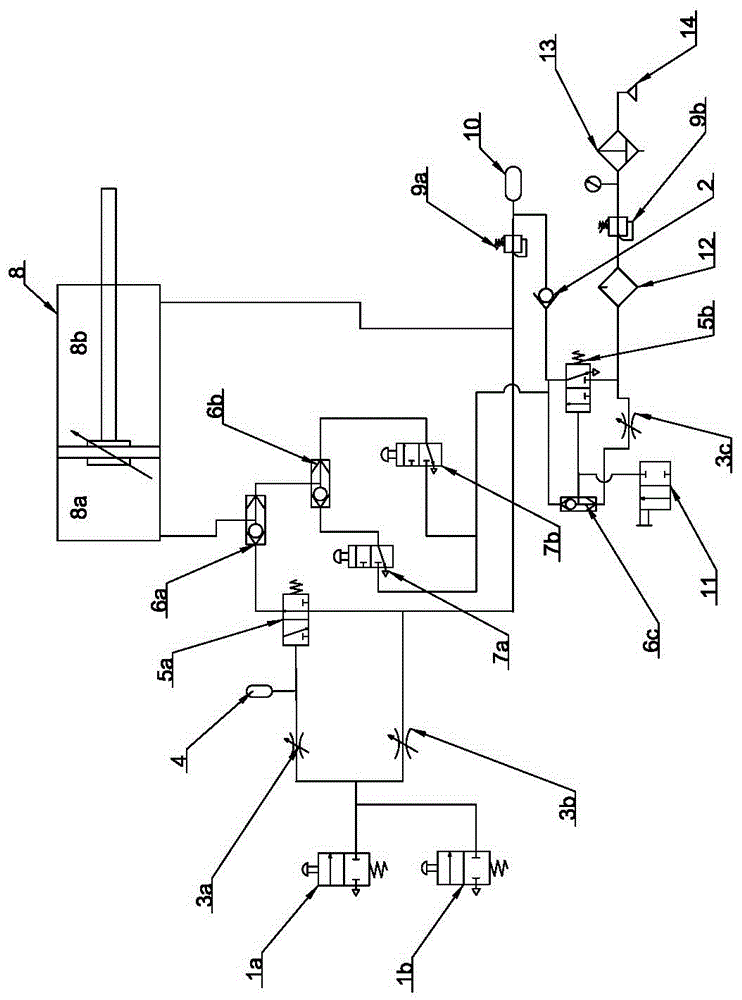

[0011] Such as figure 1 Shown is a pneumatic control system for a fire door, which includes a cylinder 8 for driving the fire door switch, a normally open door valve 7a and a normally open door valve 7b installed on the inside and outside of the door, respectively, installed on the door The inner and outer door opening button 1a and door opening button 2 1b, the air source 14 and the gas storage tank 10, the air source 14 is connected to the air-controlled reversing valve 5b and the air-controlled reversing valve after the filter 13, the pressure reducing valve 9b and the oil and gas separator 12 The inlet end of the throttle valve 1 3c, the air control reversing valve 5b is an air control two-position three-way valve, the outlet end of the air control reversing valve 5b is divided into four ways, the first way is connected to one of the shuttle valve 6C Inlet, the second path is connected to the gas tank 10 through the one-way valve 2, and the remaining two paths are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com