Hydrodynamic grouting test device simulating different filler gaps

A technology of grouting test and filling, which is applied in the field of geotechnical engineering, can solve the problems of inability to accurately reach the treatment position, inability to evaluate the water-stop effect, waste of material and man-hours, etc., to achieve light weight, save materials, improve accuracy and effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

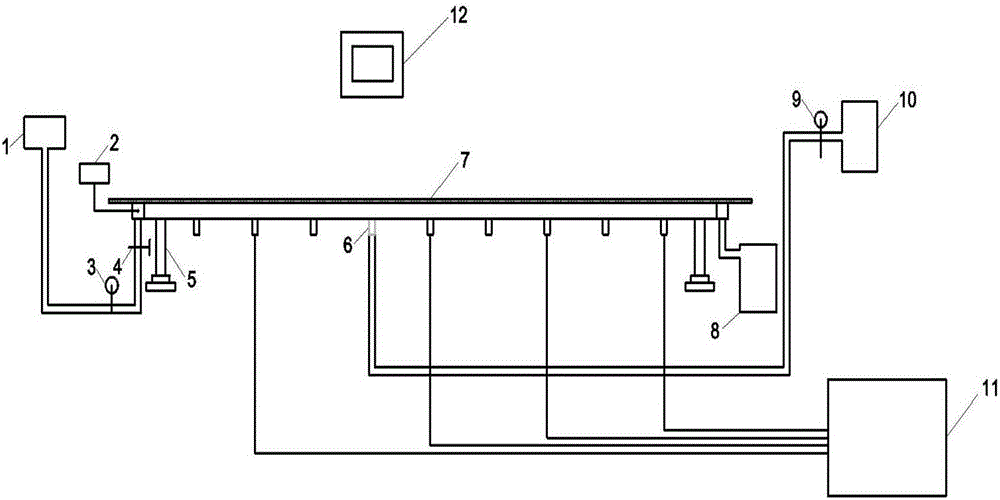

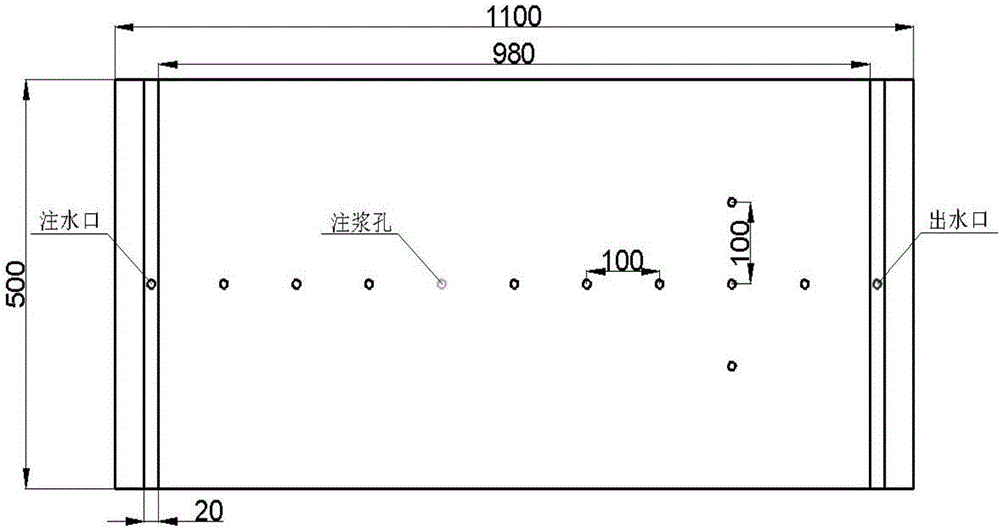

[0043] This test device is used to simulate the grouting under the dynamic water environment. The test model box is shown in the figure above. The grouting hole 6 is selected as the grouting hole, and the other small holes are used to measure the hole pressure. The two sides of the model box are respectively There are two 2cm long hollow grooves for water inlet and outlet and water pressure gauge. In this test, fine-grained quartz sand was used for experimental research. According to the geotechnical test specification, the indoor basic geotechnical test was carried out to obtain the physical property index of the test sand sample and the particle size distribution of the sand sample. See Table 1 and Table 2.

[0044] Table 1 Quartz sand density and void ratio

[0045]

[0046] Table 2 Particle size distribution table of 300g sample quartz sand test sand sample

[0047]

[0048] The grouting slurry used in the test was mixed with commercially available sodium bentonite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com