Liquefied hydrocarbon storage tank replacement and gas recovery device and method and application thereof

The technology of a recovery device and a recovery method is applied in the field of replacement gas recovery devices for liquefied hydrocarbon storage tanks, and can solve the problems of lack of devices to prevent leakage of liquefied hydrocarbons, increase of production costs of enterprises, and water entry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

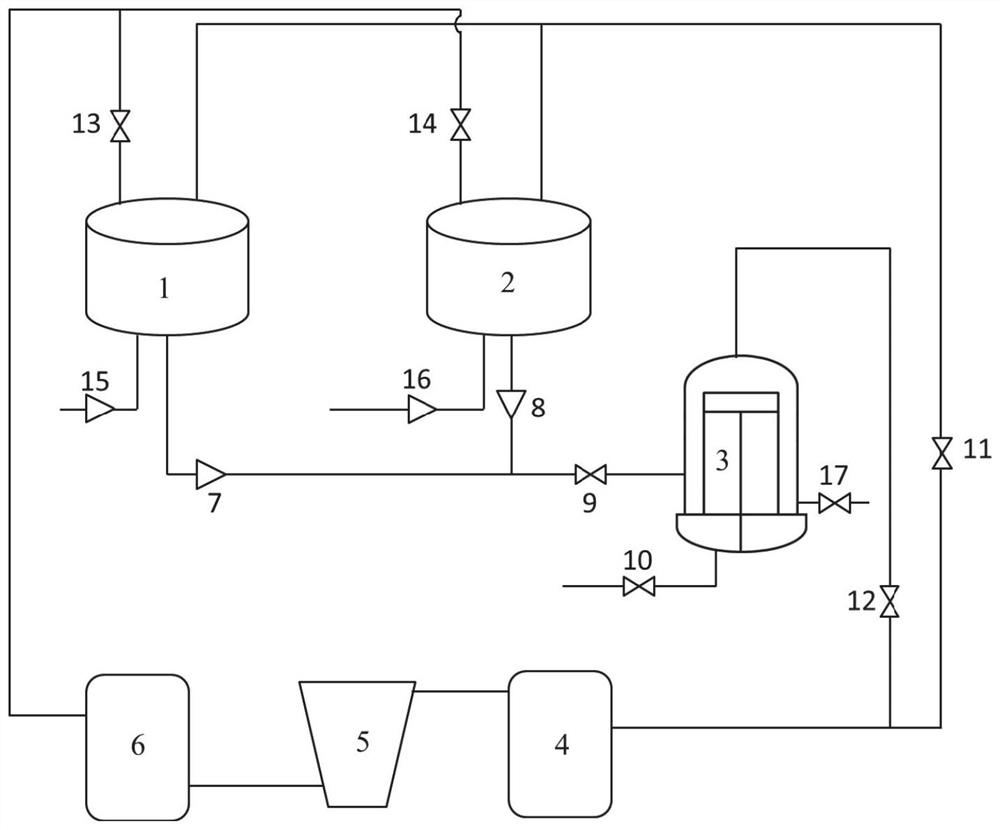

[0060] like figure 1 As shown, a liquefied hydrocarbon storage tank replacement gas recovery device includes a liquefied hydrocarbon storage tank 1 to be detected, a liquefied hydrocarbon storage tank 2, a liquefied hydrocarbon gasification separator 3, and a liquefied hydrocarbon compressor 5. One end of the liquefied hydrocarbon compressor 5 is connected to The compressor inlet buffer tank 4 is connected, the other end is connected to the compressor outlet buffer tank 6, the liquefied hydrocarbon storage tank 1 to be detected and the top of the liquefied hydrocarbon storage tank 2 are connected to the compressor inlet buffer tank 4, the liquefied hydrocarbon storage tank 1 to be detected and the top of the liquefied hydrocarbon storage tank 2 are connected to the compressor inlet buffer tank 4. The bottom of the liquefied hydrocarbon storage tank 2 is connected to the liquefied hydrocarbon gasification separator 3, and the compressor outlet buffer tank 6 is connected to the l...

Embodiment 2

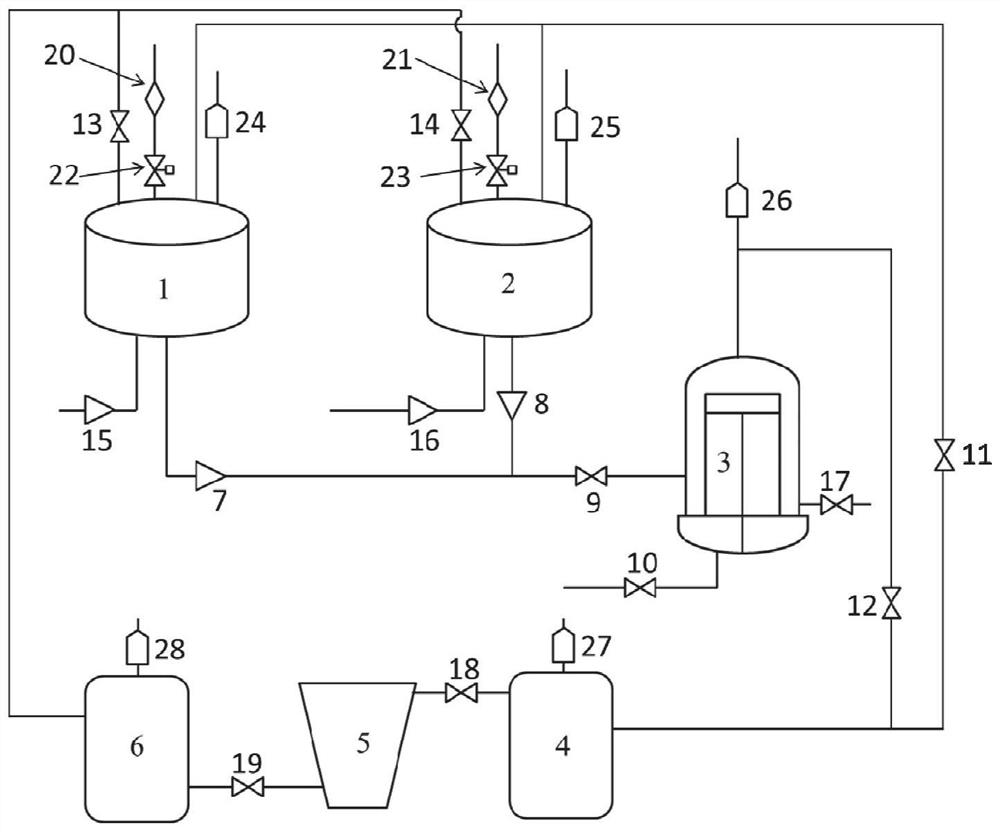

[0064] like figure 2 A liquefied hydrocarbon storage tank replacement gas recovery device shown, comprises a liquefied hydrocarbon storage tank 1 to be detected, a liquefied hydrocarbon storage tank 2, a liquefied hydrocarbon gasification separator 3, a liquefied hydrocarbon compressor 5, and one end of the liquefied hydrocarbon compressor 5 is connected to the compressor. The compressor inlet buffer tank 4 is connected, the other end is connected to the compressor outlet buffer tank 6, the liquefied hydrocarbon storage tank 1 to be detected and the top of the liquefied hydrocarbon storage tank 2 are connected to the compressor inlet buffer tank 4, the liquefied hydrocarbon storage tank 1 to be detected and the liquefied hydrocarbon storage tank 2 are connected to the compressor inlet buffer tank 4. The bottom of the hydrocarbon storage tank 2 is connected to the liquefied hydrocarbon gasification separator 3, and the compressor outlet buffer tank 6 is connected to the liquefi...

Embodiment 3

[0072] A method for recovering replacement gas from a liquefied hydrocarbon storage tank, using the liquefied hydrocarbon storage tank replacement gas recovery device of Embodiment 2 for recovery, including the transfer steps of liquid phase, gas phase, and residual liquid phase.

[0073] The liquid phase transfer step includes: the compressed gas generated by the compressor outlet buffer tank enters the liquefied hydrocarbon storage tank to be detected for pressurization, and the liquefied hydrocarbons in the liquefied hydrocarbon storage tank to be detected are transferred to the liquefied hydrocarbon storage tank;

[0074]The gas phase transfer step includes: the compressor inlet buffer tank extracts the gas phase in the liquefied hydrocarbon storage tank to be detected, and the gas phase is extracted to the liquefied hydrocarbon compressor, and transported to the liquefied hydrocarbon storage tank through the compressor outlet buffer tank;

[0075] The step of transferring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com